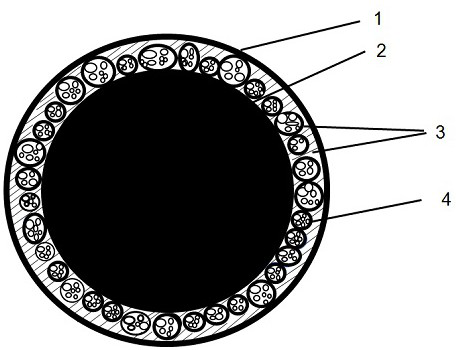

Carbon-silicon-tin compound negative electrode material and preparation method thereof

A negative electrode material and composite material technology, applied in the field of carbon-silicon-tin composite negative electrode material and its preparation, can solve the problems of peeling, poor conductivity, volume expansion, etc., to prevent separation and pulverization, avoid volume increase, and ensure close contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

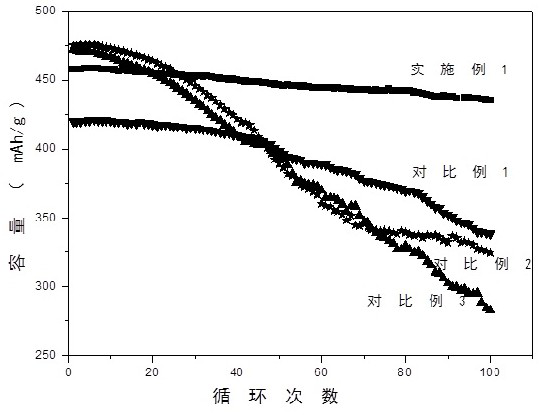

Examples

Embodiment 1

[0029] Preparation of carbon-silicon-tin composite anode materials

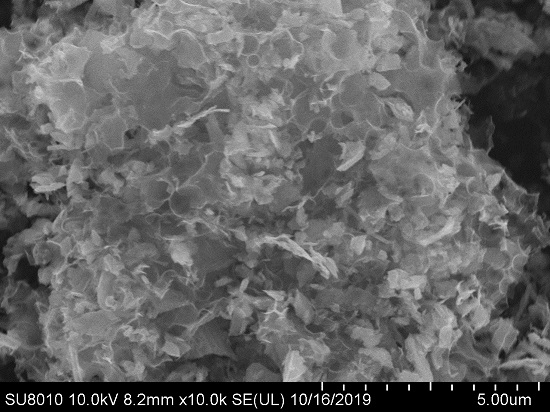

[0030]Step 1, soak silicon oxide with a particle size D50 of 2 μm in a hydrofluoric acid solution with a mass concentration of 25%, wherein the mass ratio of silicon oxide to hydrofluoric acid solution is 1:10; stir at room temperature for 2 hours, filter , the filter cake was washed with distilled water until neutral, and dried at 80°C to obtain a honeycomb silicon-based material;

[0031] Step 2, mix stannous chloride and water at a mass ratio of 1:10, and slowly add 0.01mol / L hydrochloric acid dropwise under stirring until clarification;

[0032] Step 3: add the honeycomb silicon-based material obtained in Step 1 into the solution prepared in Step 2 and completely immerse it, and stir for 3 hours; slowly add dropwise an ammonia solution with a mass concentration of 30%, so that the pH of the solution is 8, and continue stirring for 3 hours;

[0033] Step 4: filter with suction, wash the filter cake until ...

Embodiment 2

[0046] 1. Preparation of carbon-silicon-tin composite anode materials

[0047] Step 1, the particle size D 50 Soak silicon oxide with a thickness of 0.5 μm in a hydrofluoric acid solution with a mass concentration of 5%, wherein the mass ratio of silicon oxide to hydrofluoric acid solution is 1:5; stir at room temperature for 0.5 h, filter, and use distilled water for the filter cake Wash until neutral, and dry at 40°C to obtain a honeycomb silicon-based material;

[0048] Step 2, mix stannous chloride and water at a mass ratio of 1:10, and slowly add 0.01mol / L hydrochloric acid dropwise under stirring until clarification;

[0049] Step 3: Add the honeycomb silicon-based material obtained in Step 1 into the solution prepared in Step 2 and completely immerse it, and stir for 3 hours; slowly add dropwise an ammonia solution with a mass concentration of 50%, so that the pH of the solution is 4, and continue stirring for 5 hours;

[0050] Step 4: filter with suction, wash the fi...

Embodiment 3

[0056] 1. Preparation of carbon-silicon-tin composite anode materials

[0057] Step 1, the particle size D 50 Nano-silicon with a diameter of 100nm is soaked in hydrofluoric acid solution with a mass concentration of 5%, wherein the mass ratio of nano-silicon to hydrofluoric acid solution is 1:10; stir at room temperature for 0.5h, filter, and wash the filter cake with distilled water to medium properties, drying at 60°C to obtain a honeycomb silicon-based material;

[0058] Step 2, mix stannous chloride and water at a mass ratio of 1:50, and slowly add 0.01mol / L hydrochloric acid dropwise under stirring until clarification;

[0059] Step 3: add the honeycomb silicon-based material obtained in Step 1 into the solution prepared in Step 2 and completely immerse it, and stir for 0.5 h; slowly add dropwise an ammonia solution with a mass concentration of 10%, so that the pH of the solution is 7, and continue stirring for 2 h;

[0060] Step 4: filter with suction, wash the filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com