Mechanical double energy storage impact mechanism and impact method

An impact mechanism and double energy storage technology, which is applied in the direction of power hammer and hammer driving device, etc., can solve the problem of high stress at the contact point between the impact head and the impacted object, high equipment cost and maintenance cost, and large working force of the pneumatic impact mechanism. problem, achieve good energy saving effect, reduce equipment and labor costs, and achieve accurate impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

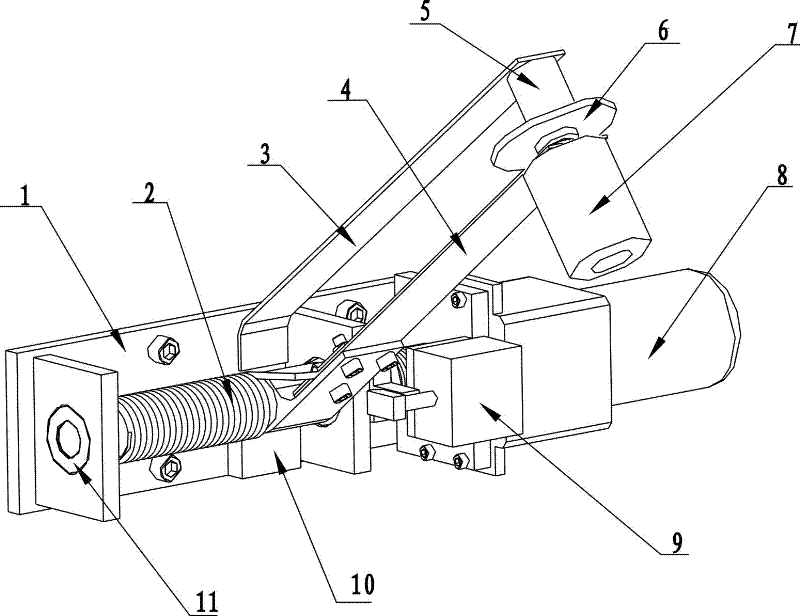

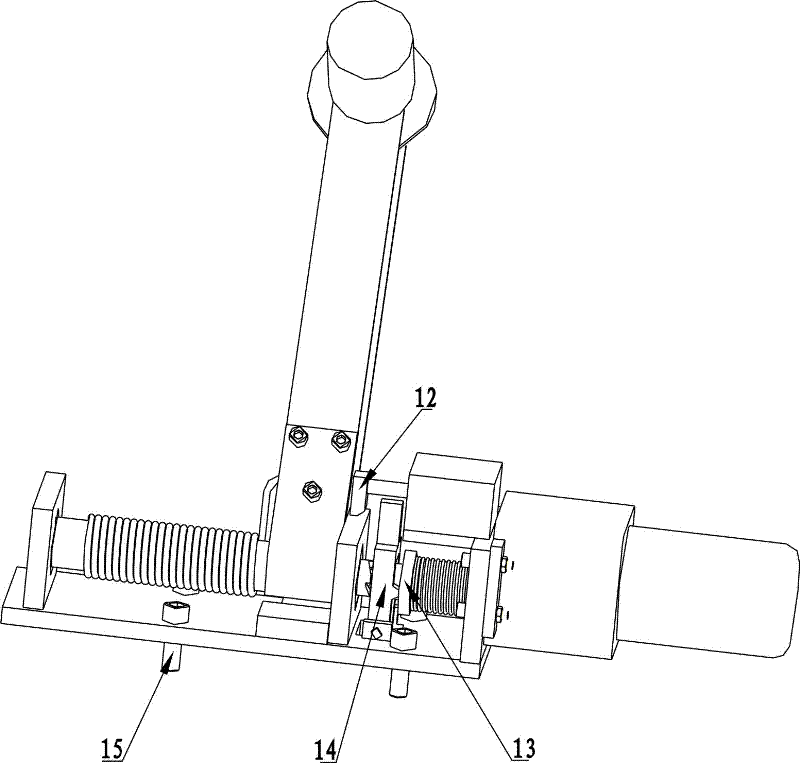

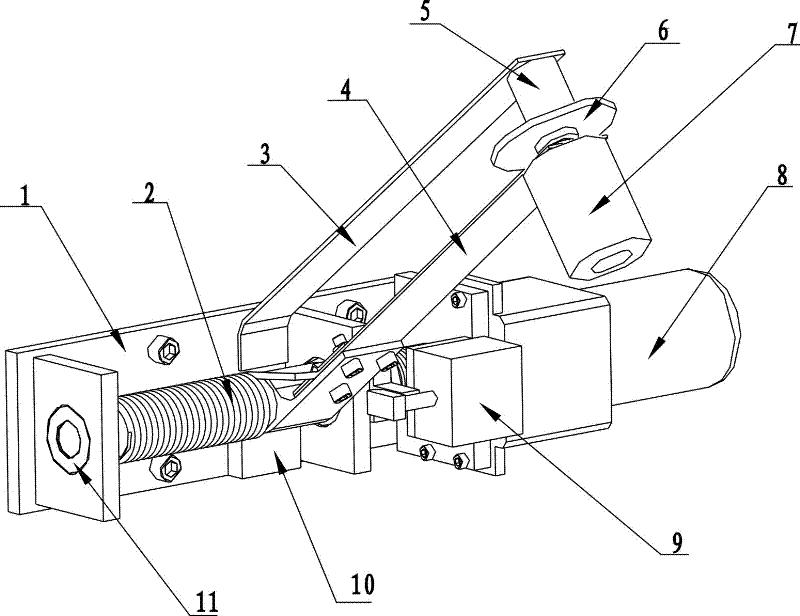

[0038] Such as figure 1 , figure 2 As shown, the mechanical double energy storage impact mechanism of the present invention consists of a frame 1, a torsion spring 2, an auxiliary positioning electromagnet mounting arm, a swing arm, an auxiliary positioning electromagnet, a suction plate 6, a hammer head 7, and an electric drive mechanism 8 , clutch electromagnet, buffer block 10, bearing 11, rotating shaft 12, drag hook 13, gear clutch 14, lever 15, mounting screw 16 and form.

[0039] The frame 1 plays a supporting role for the whole mechanism, and is installed on the corresponding position of the main equipment by screws 16 . The rotating shaft 12 is installed and positioned on the frame 1 through the bearing 11 . The torsion spring 2 and the rotating shaft 12 are coaxially installed, one end is fixed on the swing arm 4, and the other end is fixed on the frame 1.

[0040] The electric drive mechanism 8, the clutch electromagnet, and the buffer block 10 are installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com