Convenient hydraulic electrohydraulic hammer

An electro-hydraulic hammer and hydraulic technology, which is applied in the direction of power hammer, light impact tool, hammer driving device, etc., can solve the problems of large buffer piston outer diameter, high equipment height, easy failure, etc., and achieve the overall height reduction and convenient maintenance , the effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

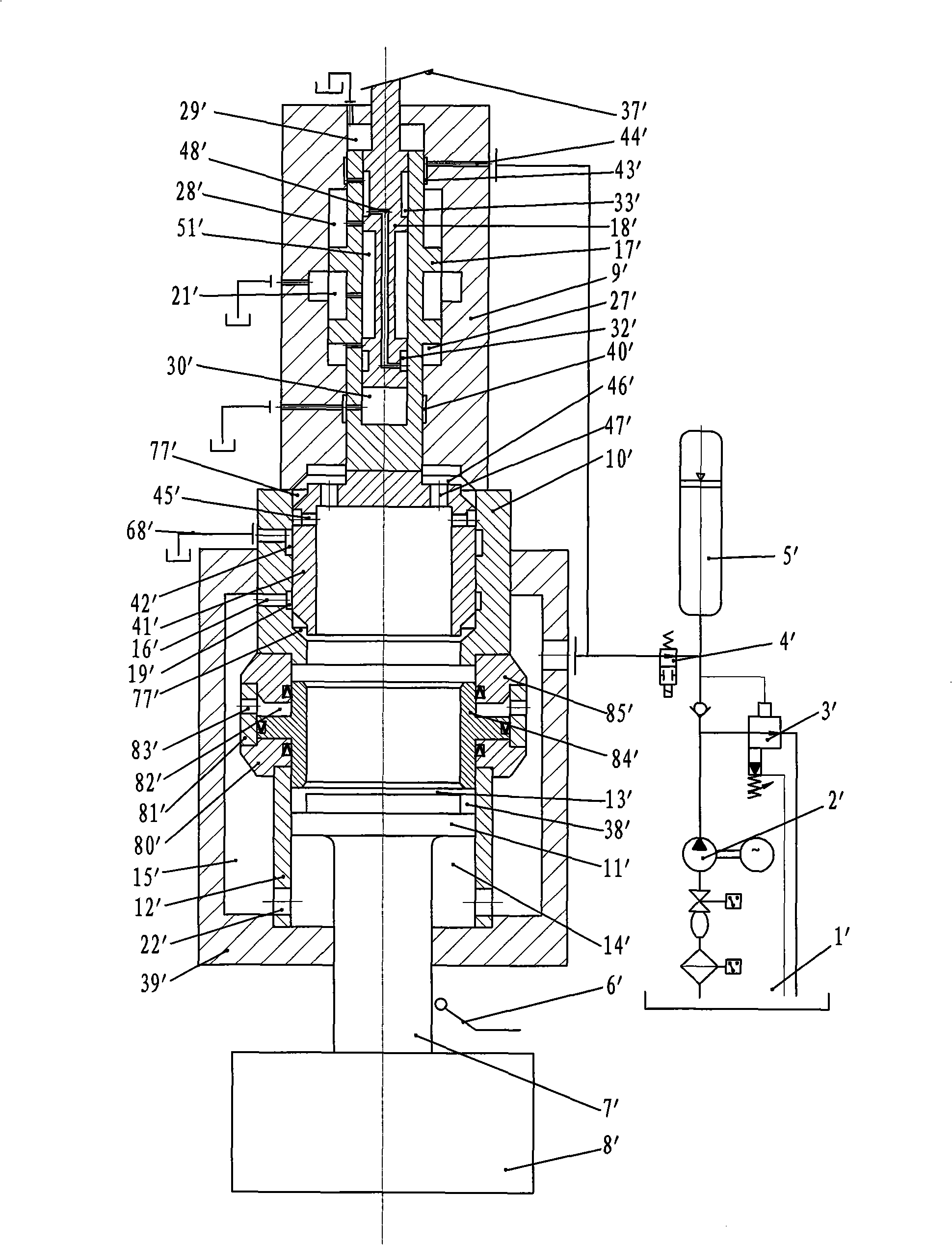

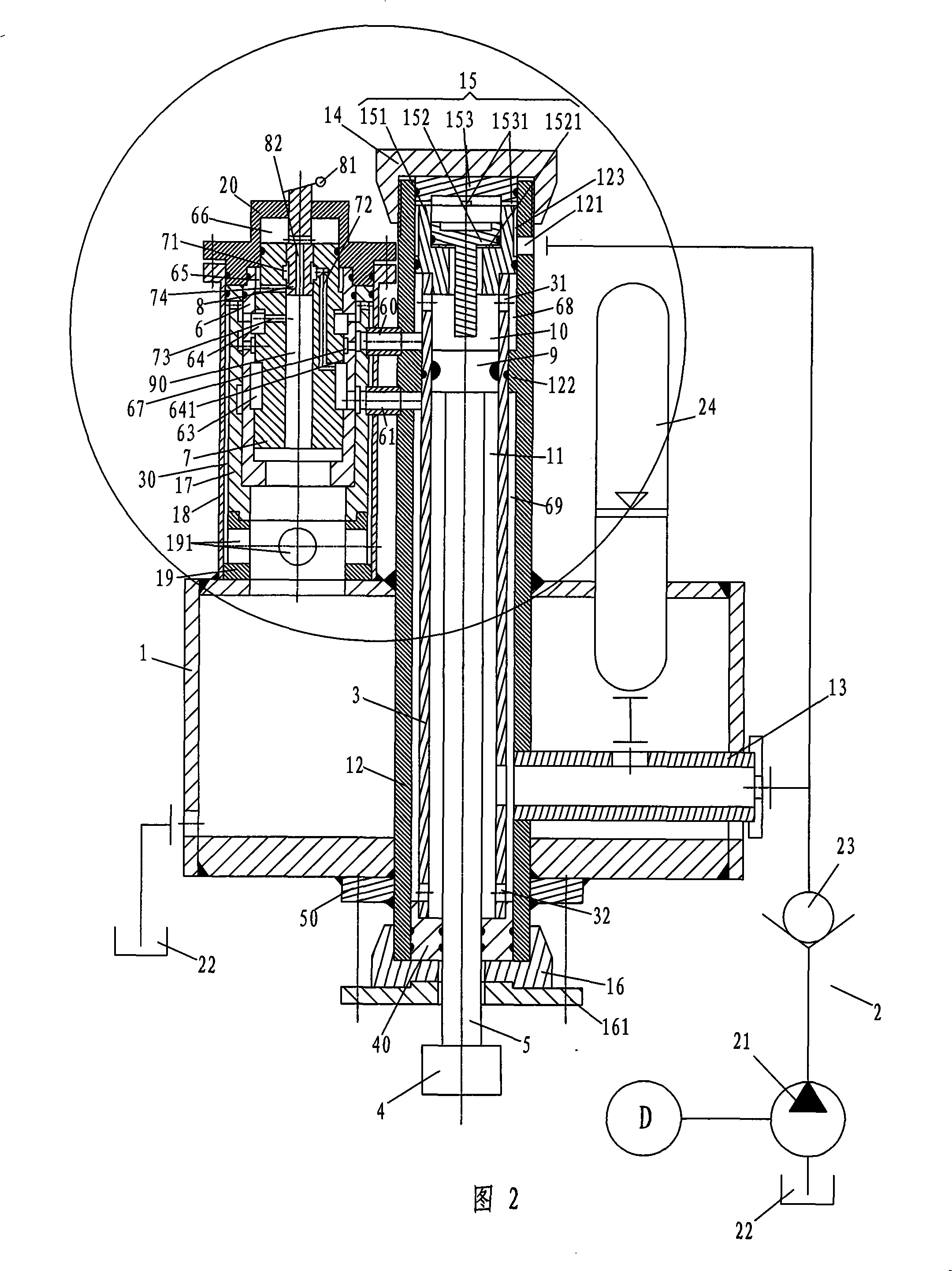

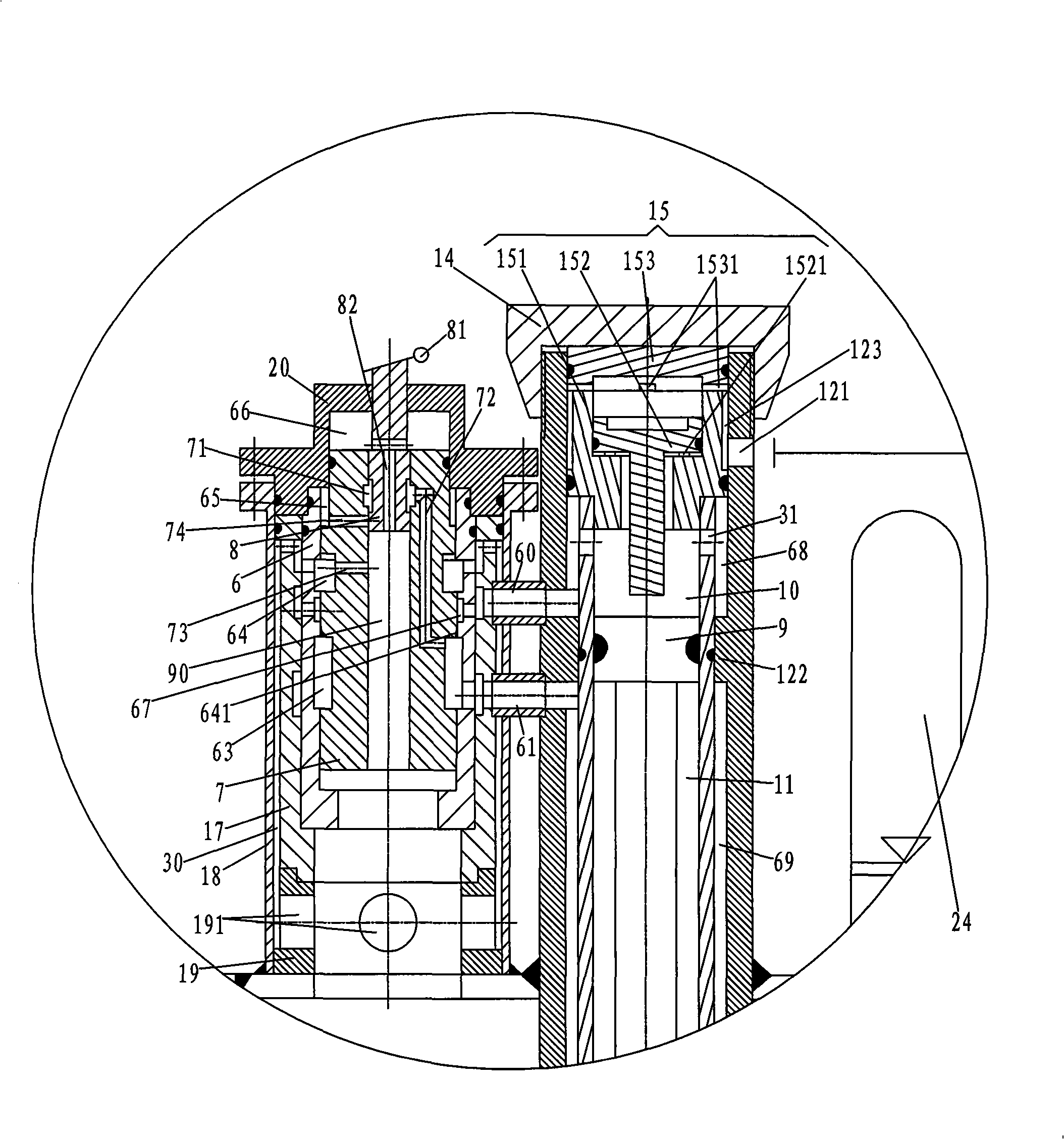

[0021] Please refer to the structural representation of the convenient hydraulic electro-hydraulic hammer of the present invention shown in Fig. 2 and image 3As shown in the partial enlarged view, the hydraulic electro-hydraulic hammer includes a base 1, a hydraulic source 2, an oil cylinder 3, a hammer rod 5 with a hammer head 4 at the lower end of the inner cavity of the oil cylinder 3, a valve sleeve 6, and a valve sleeve 6. The follow-up valve 7 and the spool 8 provided by sliding in the inner chamber of the follow-up valve 7, the upper end of the spool 8 is connected with the spool control rod 81, the inner cavity of the follow-up valve 7 at the bottom of the spool 8 is a low-pressure passage 90, and the hammer rod 5. The upper end is connected to the piston 9. The upper and lower ends of the piston 9 have an upper cylinder chamber 10 and a lower cylinder chamber 11. The effective working area of the piston 9 in the upper cylinder chamber 10 is larger than that in the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com