Variable-speed circumferential low-stress bending fatigue crack precise blanking machine and blanking method thereof

A bending fatigue and precision blanking technology, which is applied in the direction of power hammer, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of instantaneous breaking of bars, long total blanking time, uneven force, etc., and achieve vertical fracture Smooth, high material utilization, no radial distortion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

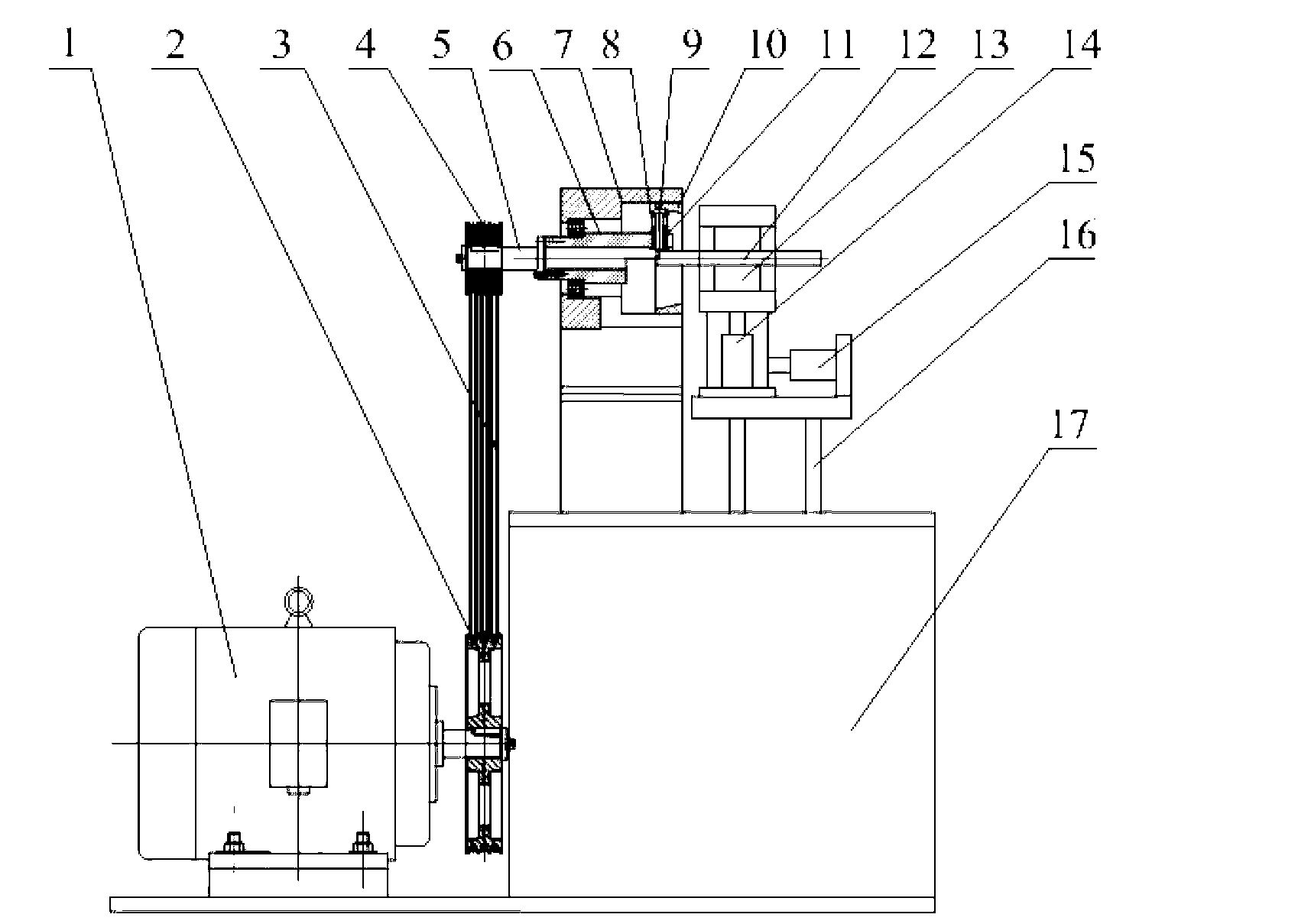

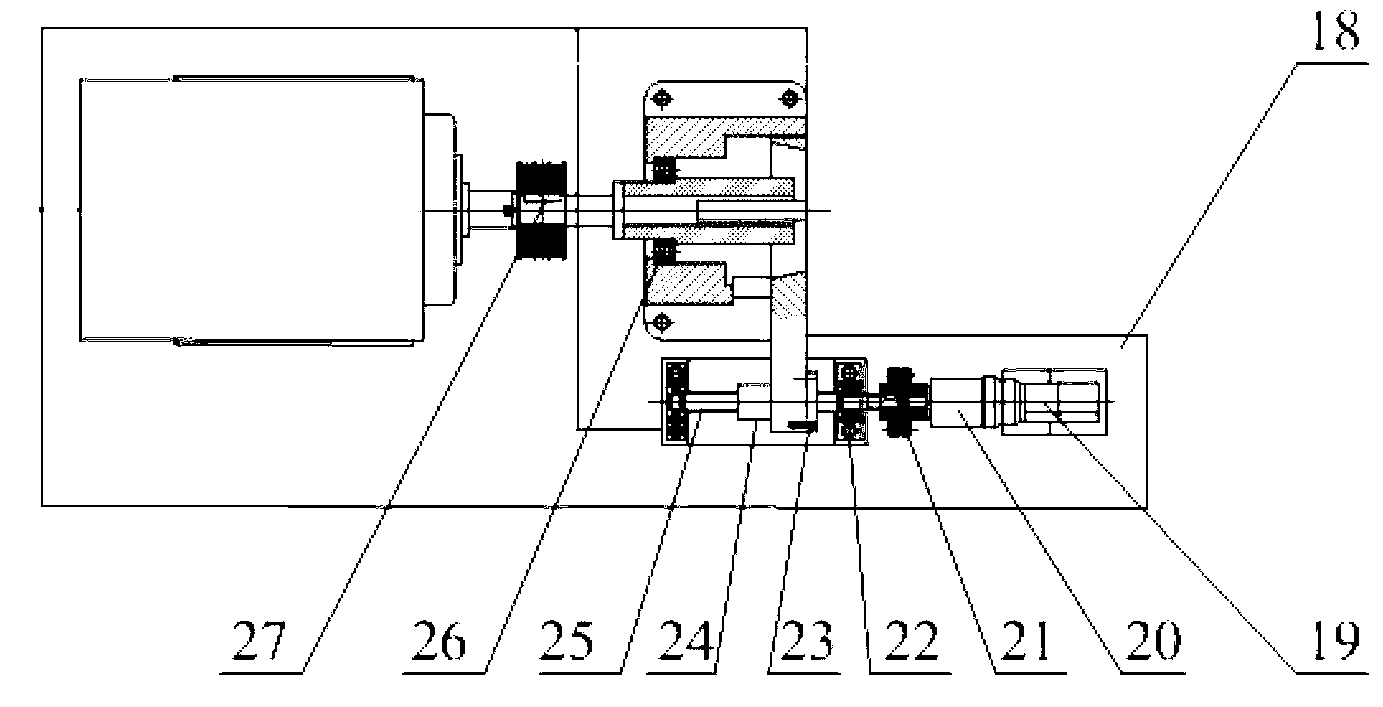

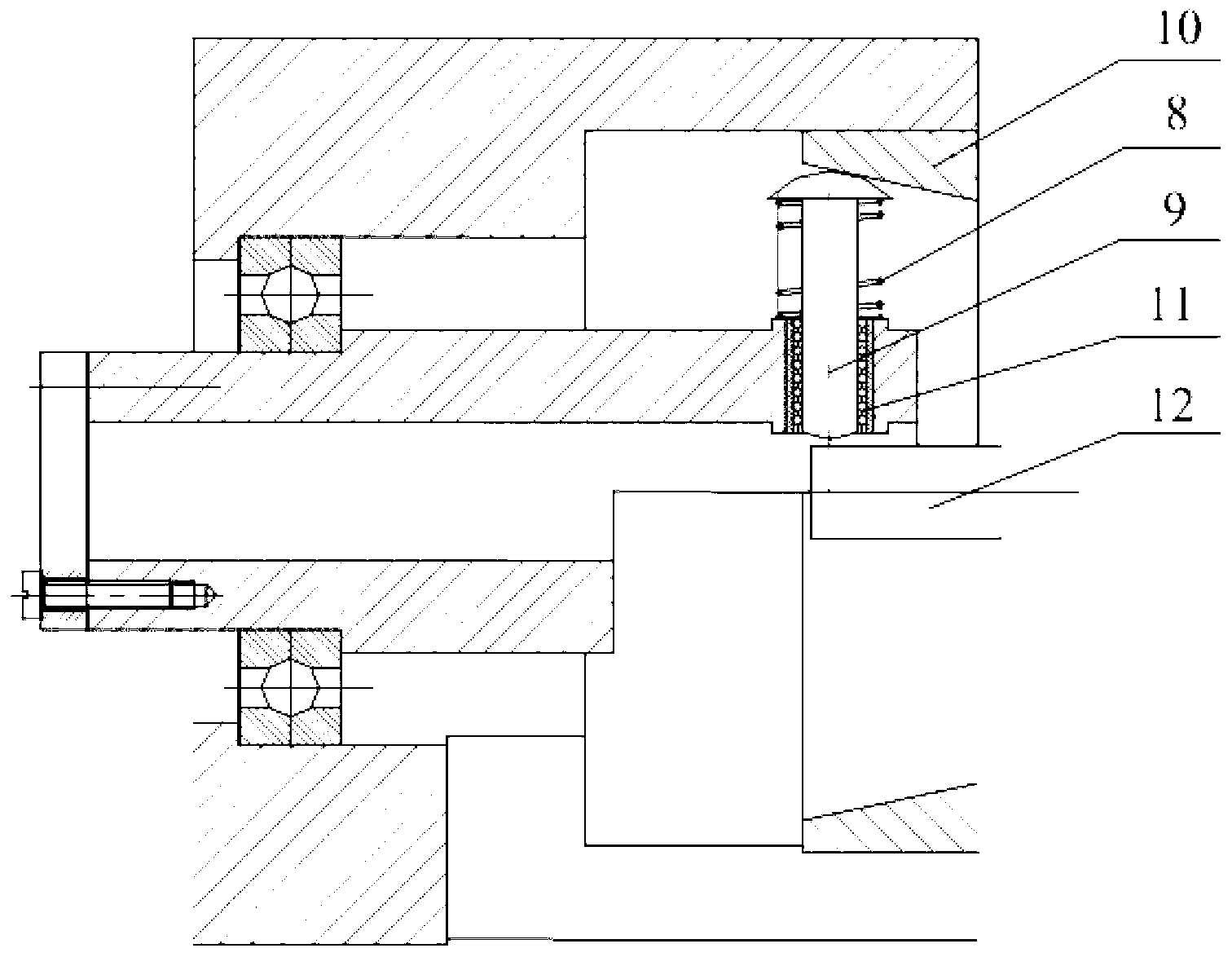

[0029] like figure 1 , figure 2 and image 3 A variable-speed circumferential low-stress bending fatigue fracture precision blanking machine is shown, including frequency conversion motor 1, large pulley 2, V-shaped belt 3, small pulley 4, two-stage gear accelerator 5, high-speed main shaft 6, and sliding guide rails Support seat 7, spiral compression spring 8, columnar hammer head 9, feed sleeve 10, ball guide bush 11, metal bar 12, gripper 13, clamping cylinder 14, feeding cylinder 15, hydraulic clamping and feeding mechanism Bracket 16, body 17, seat plate 18, servo motor 19, reducer 20, coupling 21, ball screw support seat 22, screw 23, nut 24, ball screw 25, deep groove ball bearing 26 and key 27 The frequency conversion motor 1 is connected with the large pulley 2; the large pulley 2 is connected with the small pulley 4 through the V-belt 3; the small pulley 4 is fixed on the input shaft of the two-stage gear accelerator 5 through the key 27 Above; the output shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com