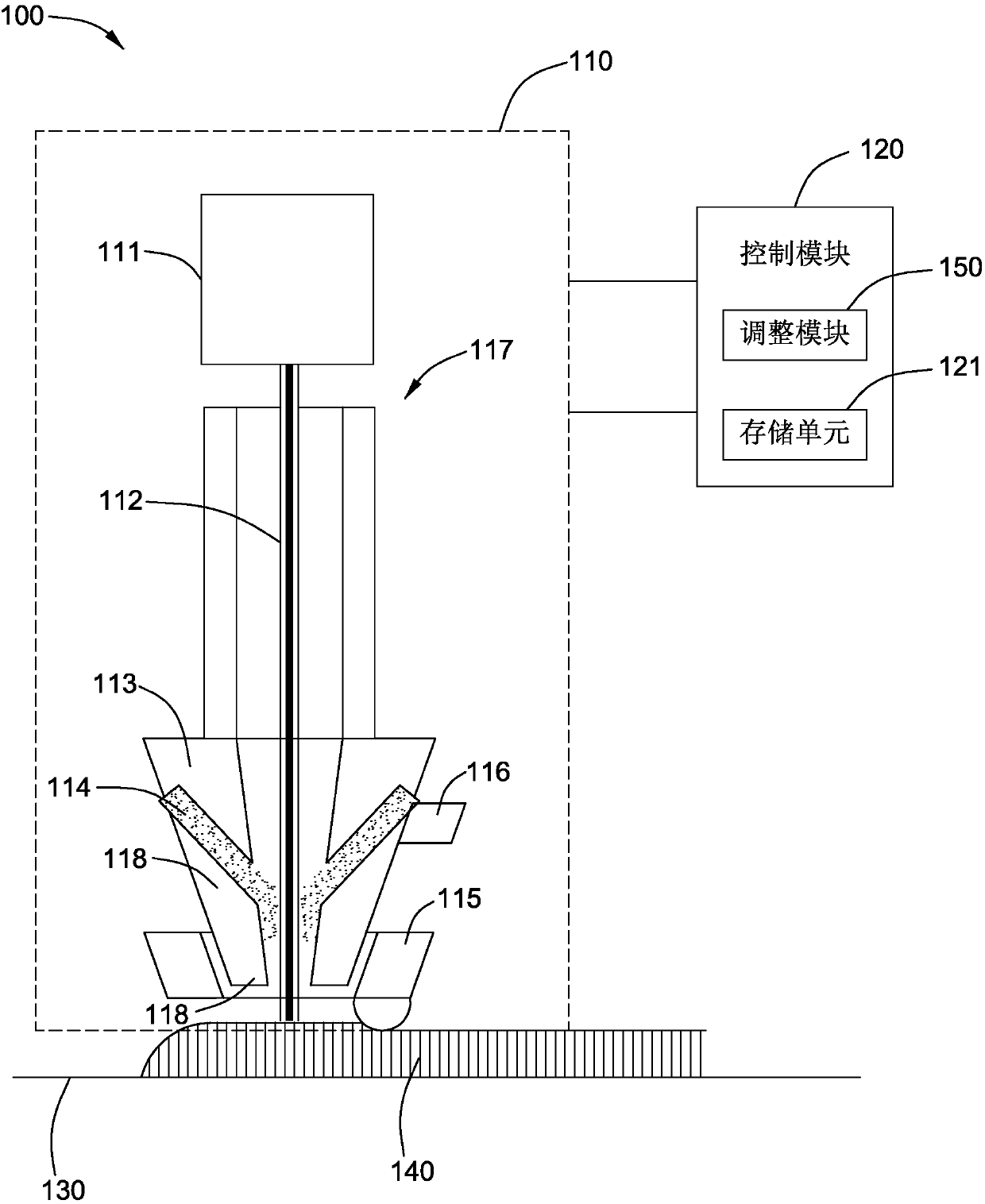

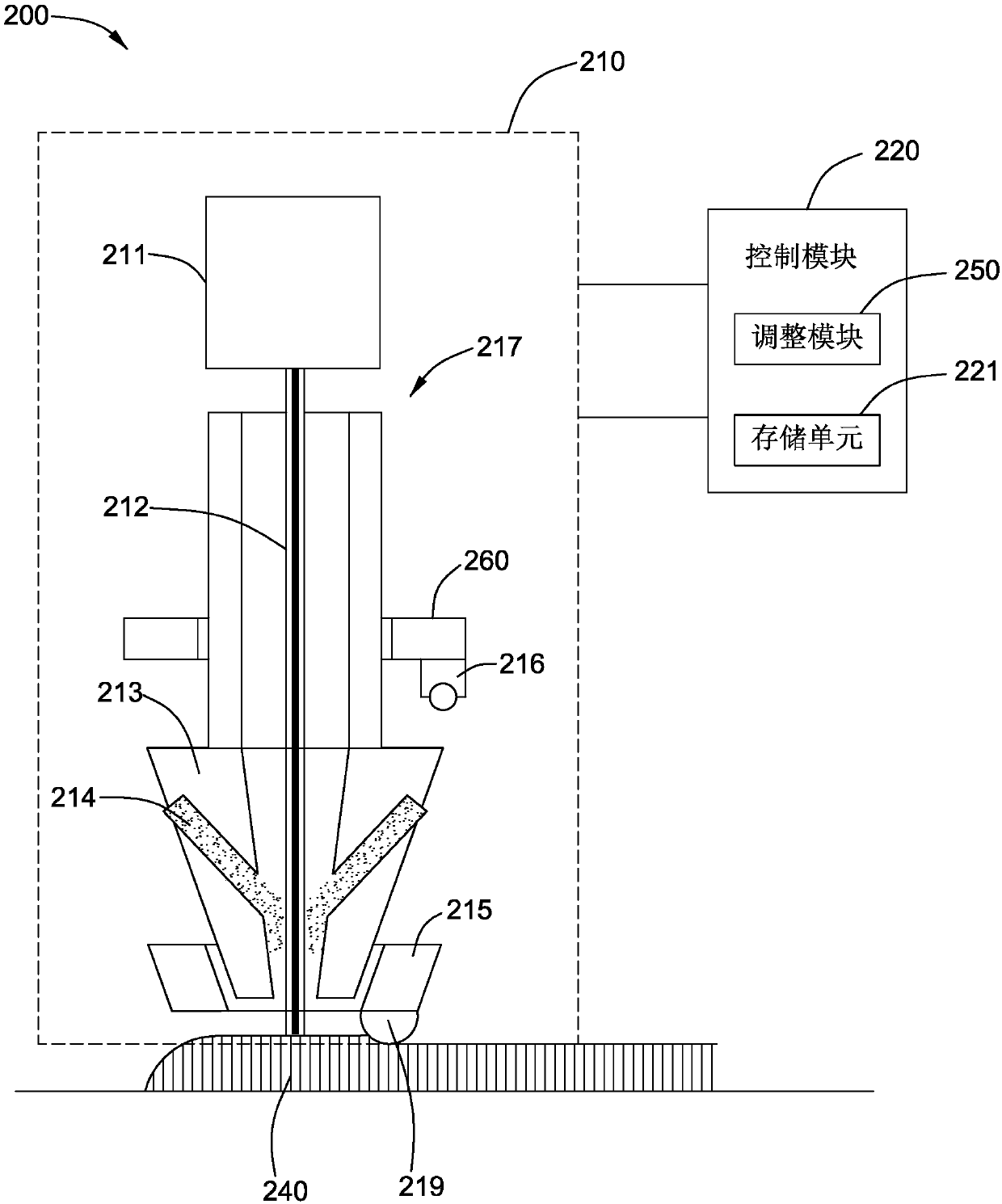

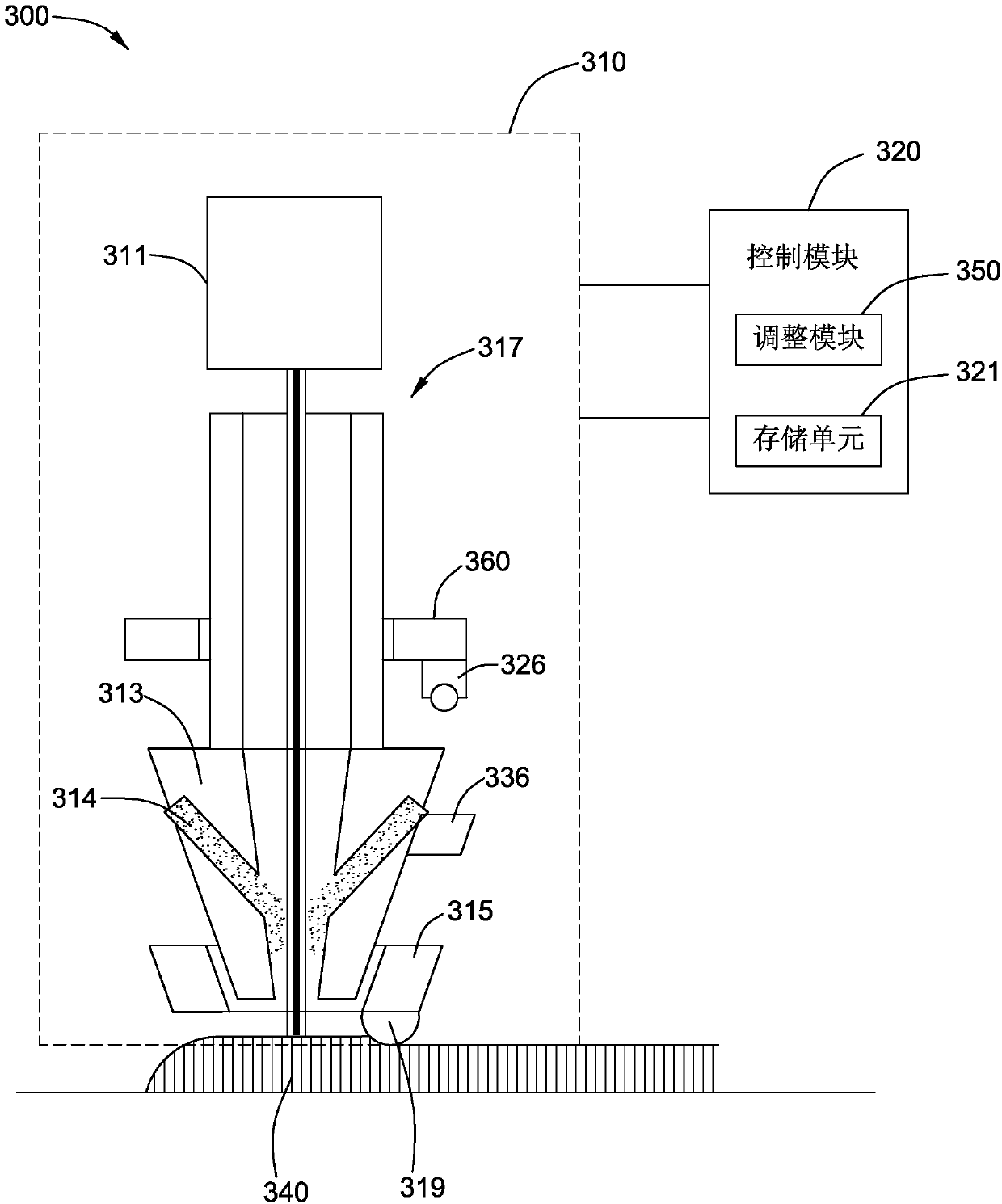

Temperature controlling system and method for additive manufacturing

A temperature control system and additive manufacturing technology, applied in the field of additive manufacturing, can solve problems such as affecting the scope of application of materials and forging effects, high complexity of processes and equipment, and monitoring forging positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As used herein, "comprises," "comprising," or "having" and similar words mean that in addition to the items listed thereafter and their equivalents, other items may also be within the scope. Approximate terms in the present application are used to modify the quantity, which means that the present invention is not limited to the specific quantity, but also includes the modified parts that are close to the stated quantity, acceptable, and will not cause changes in the relevant basic functions.

[0029] In the specification and claims, unless clearly stated otherwise, all items are not limited to singular or plural. Unless the context clearly dictates otherwise, the terms "or" and "or" do not imply exclusion, but mean that at least one of the mentioned items (eg, ingredients) is present, and includes situations where combinations of the mentioned items may be present.

[0030] The reference to "some embodiments" and the like in the description of the present application me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com