Processing method of amorphous alloy stator core slot and locking and positioning clamp thereof

An amorphous alloy, stator core technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., to achieve the effects of low cost, high efficiency and long processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

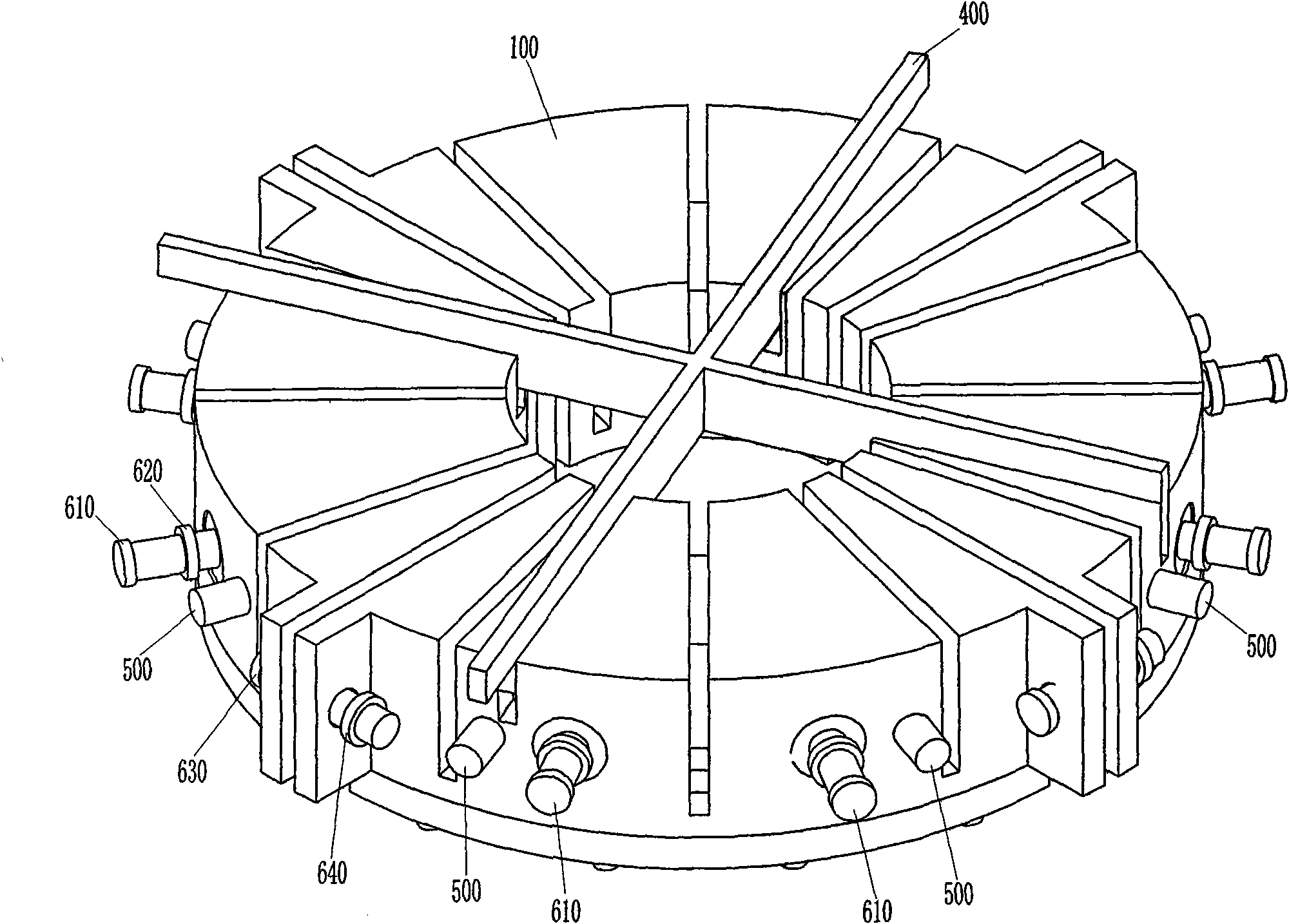

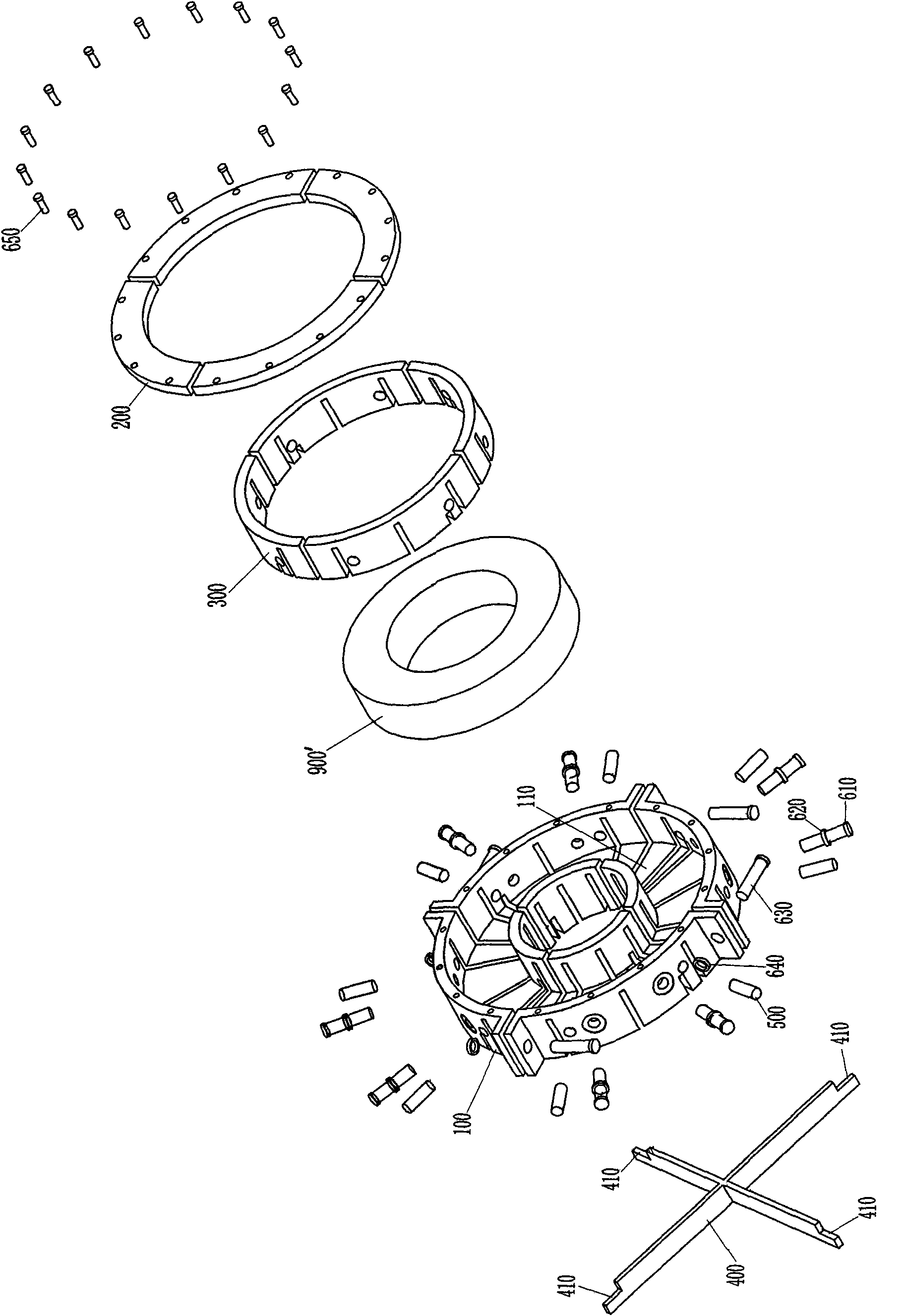

[0078] see Figure 2 to Figure 13 , Figure 22 and Figure 23 , the present invention is used to process the locking and positioning fixture of the amorphous alloy stator core slot, including a housing 100, a bottom plate 200, a moving clamping ring 300, a positioning plate 400, eight clamping bolts 610, and four fixing bolts 630 , four fixing nuts 640, eight positioning pins 500 and sixteen screws 650; the housing 100 is a cylinder 120 provided with a bottom surface 110, and the cylinder is provided with a cylinder body 130 upward from the central part of the bottom surface 110 inner wall, The outer diameter of the cylinder body 130 is adapted to the inner diameter of the stator core 900' to be processed, the cylinder body 130 and the bottom surface 110 are provided with the same central through hole 140, the outer wall of the cylinder body 130, the inner wall of the cylinder 120 and the bottom surface 110 The inner wall forms a cavity 150, and the ring wall of the cylinder...

specific Embodiment 2

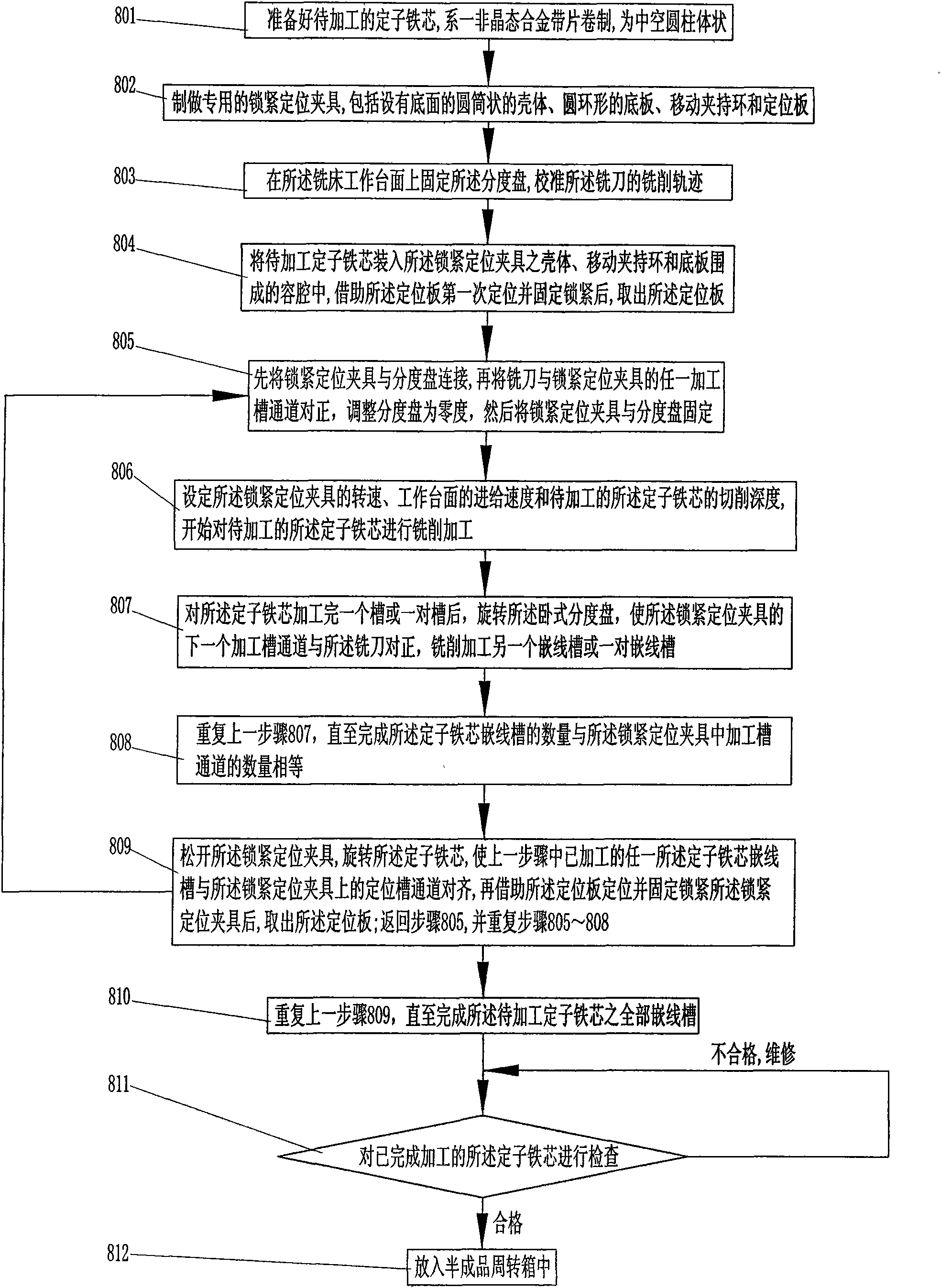

[0083] see Figure 1 to Figure 3 and Figure 14 to Figure 23 , the processing method of the amorphous alloy stator core groove of the present invention adopts milling processing, and the equipment used includes the horizontal milling machine equipment for completing the cutting processing task of the amorphous alloy stator core 900′ to be processed, and completing the stator iron core to be processed. The horizontal indexing plate for rotating and positioning the core 900 ′, the disc milling cutter for radially cutting the stator core 900 ′ to be processed, and the locking and positioning fixture for radially clamping and positioning the stator core 900 ′ The locking and positioning fixture adopts the locking and positioning fixture in the first embodiment. In this embodiment, the width dimension of the processing groove channel 160 of the housing 100 in the locking and positioning fixture, the moving clamp The width dimension of the processing groove passage 360 of the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com