Recycling device of waste plastic

A recycling device and waste plastic technology, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of time-consuming transfer, high investment cost, discontinuous processing, etc., achieve compact structure, reduce input cost, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

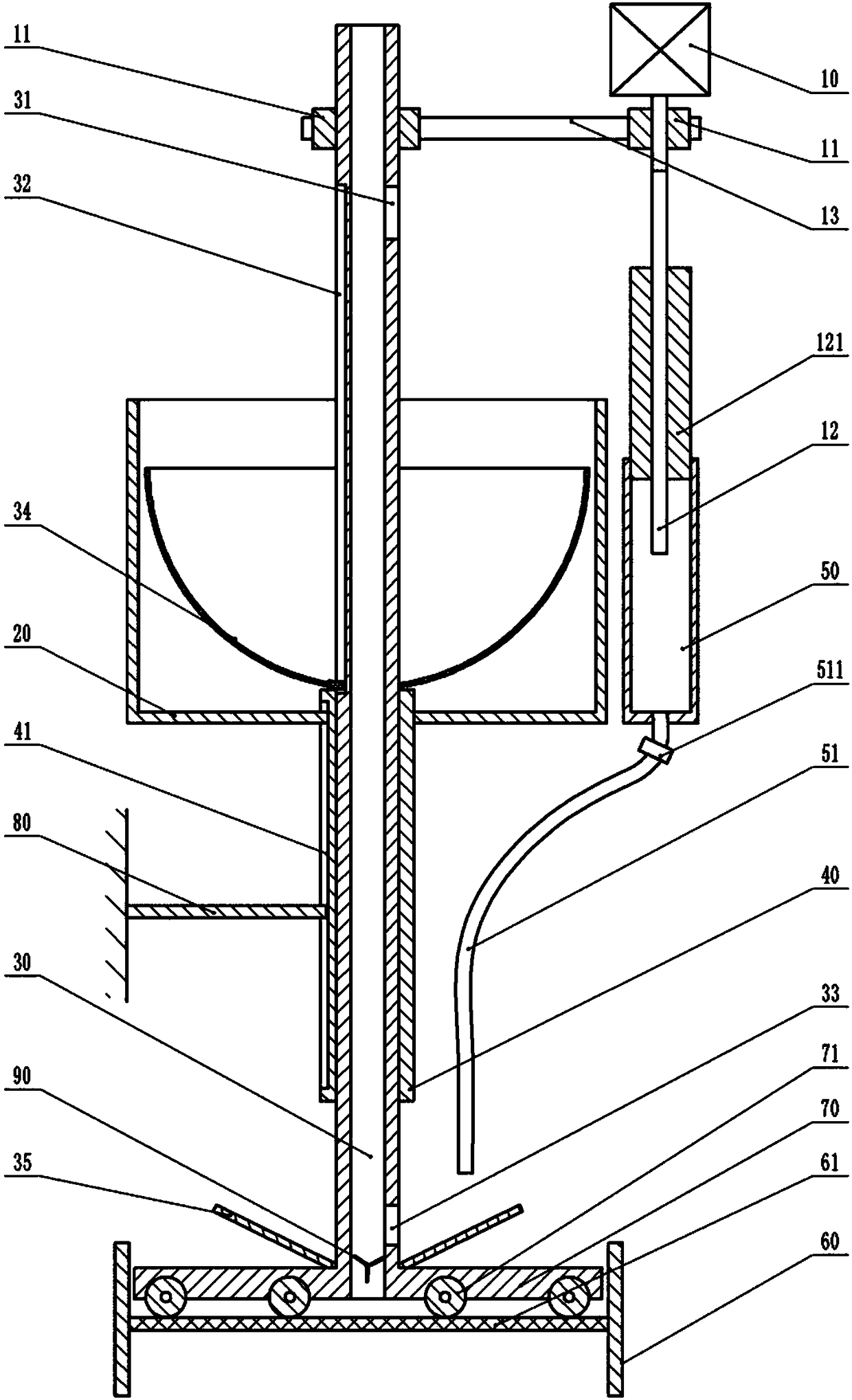

[0018] Instructions attached figure 1 The reference signs in include: motor 10, friction wheel 11, threaded rod 12, plunger 121, belt 13, cleaning tank 20, hollow shaft 30, feed port 31, strip groove 32, feed port 33, hemispherical screen 34 , Conical funnel 35, top column 40, card slot 41, feeding cylinder 50, discharge pipe 51, one-way discharge valve 511, rolling cylinder 60, rigid sieve plate 61, pressure plate 70, pressure roller 71, limit rod 80.

[0019] like figure 1 As shown, the waste plastic recycling device includes a cleaning unit, a power unit, a crushing unit, a feeding unit and a mixing unit. The cleaning unit includes a cleaning tank 20, a hollow rotating shaft 30, a hemispherical sieve 34, a top post 40 and a limit rod 80. The surface of the hollow rotating shaft 30 is provided with bar-shaped grooves 32 distributed along the height direction, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com