Extruding device for thermosetting powder coating production

A technology of thermosetting powder and coating, which is applied in the direction of mixer with rotating stirring device, transportation, packaging, dissolution, etc. It can solve the problems of thermosetting powder coating residue, thermosetting powder coating waste, and affecting the coating process, so as to reduce residue, The effect of avoiding waste, increasing heating speed and heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

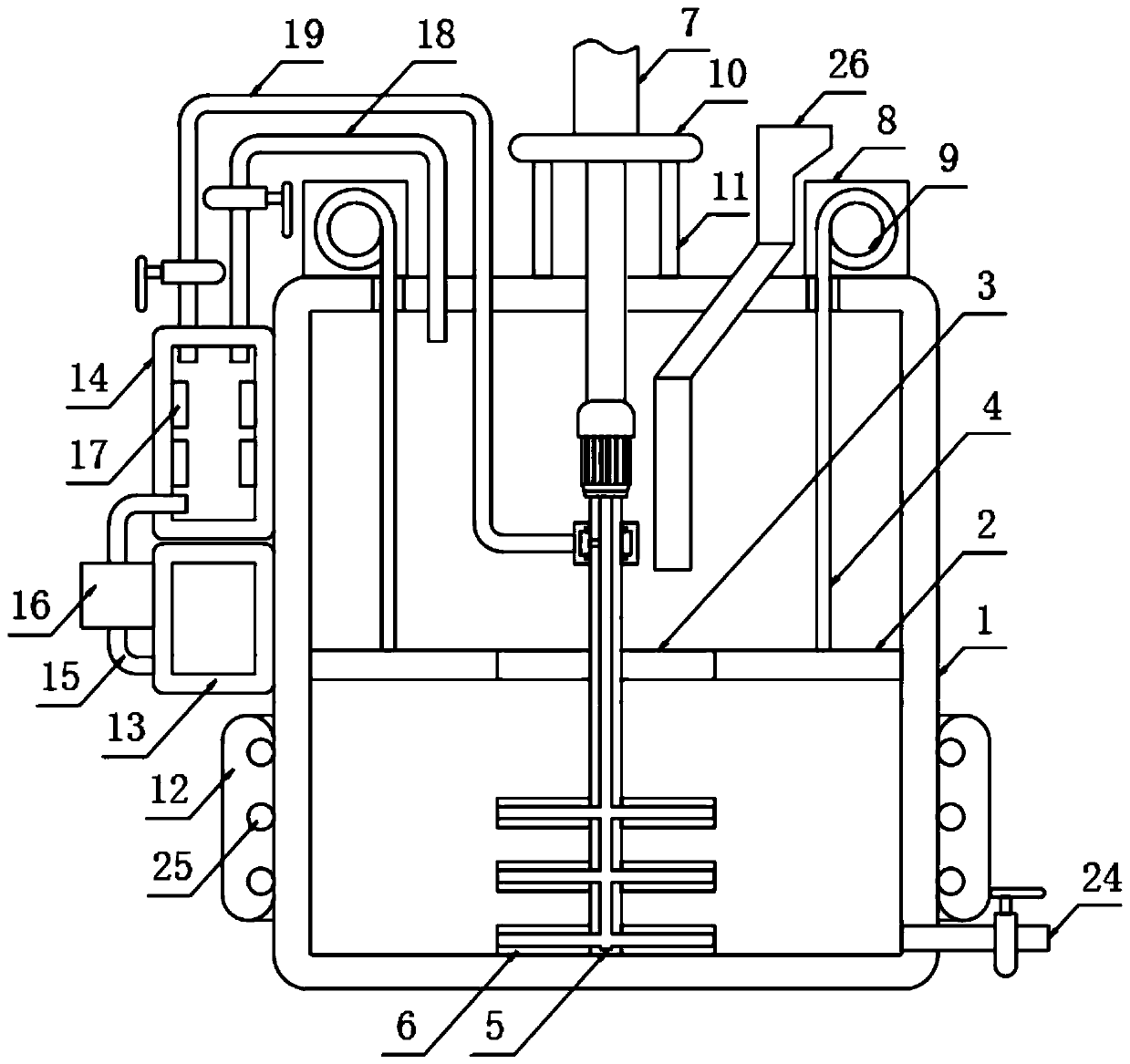

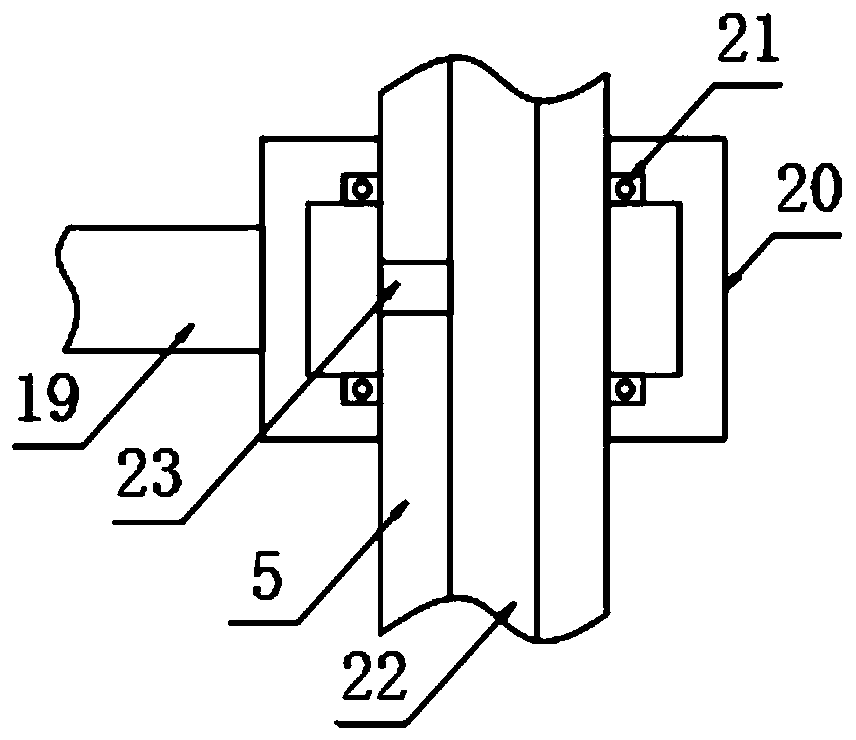

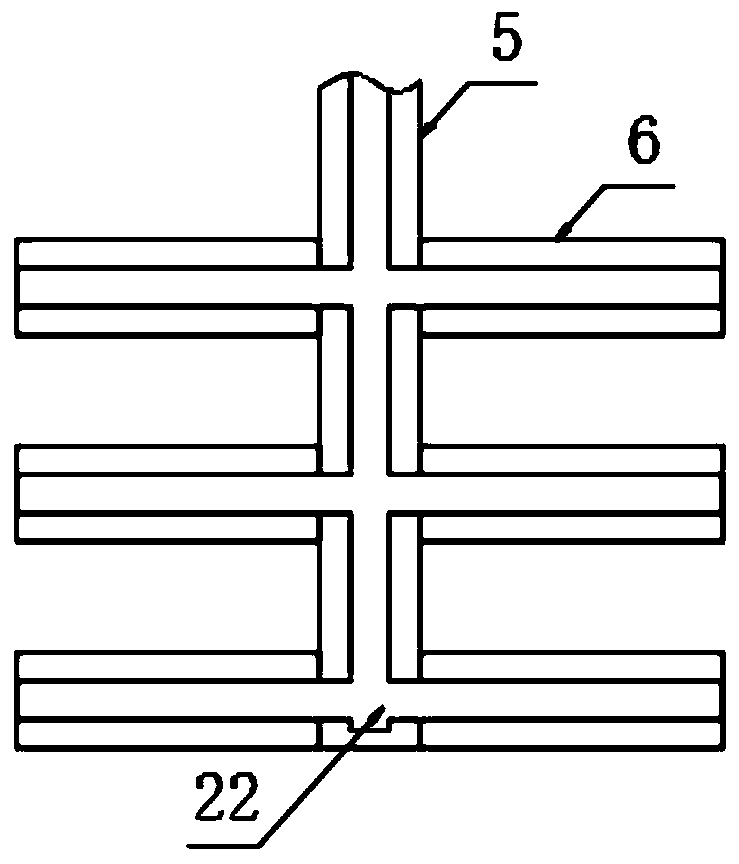

[0024] The present invention provides such as Figure 1-3 A thermosetting powder coating production extrusion device shown includes a housing 1, a scraper 2 is provided inside the housing 1, the edge of the scraper 2 is attached to the housing 1, and the scraper 2 runs through A through hole 3 and a steel wire rope 4 are fixed on the top, a stirring rod 5 is fixed inside the through hole 3, and a stirring plate 6 is sleeved on the outside of the stirring rod 5, and the stirring plate 6 is connected to the through hole 3. Adaptation, the top of the stirring rod 5 is fixed with a cylinder 7, the bottom of the cylinder 7 is fixed with a top plate 10, the bottom of the top plate 10 is fixed with a mounting rod 11, and the mounting rod 11 is fixed on the top of the housing 1 , the top of the housing 1 is fixed with a winding machine 8, the winding machine 8 is provided with a winding wheel 9, and the steel wire rope 4 is fixed on the outside of the winding wheel 9.

[0025] It can...

Embodiment 2

[0027] Further, in the above-mentioned embodiment 1, the outer side of the housing 1 is sleeved with a thermal insulation cover 12 , and the thermal insulation cover 12 is provided with a heating pipe 25 inside.

[0028] Further, in the first embodiment above, the side of the housing 1 is fixed with a gas storage chamber 13 and a heating chamber 14, the gas storage chamber 13 is arranged at the bottom of the heating chamber 14, and the inside of the gas storage chamber 13 is filled with Inert gas, the inert gas is set as nitrogen.

[0029] Further, in the first embodiment above, a connecting pipe 15 is provided on the side of the gas storage chamber 13 and the heating chamber 14 , an air pump 16 is provided on the connecting pipe 15 , and a heating element 17 is provided inside the heating chamber 14 .

[0030] Further, in the first embodiment above, the top of the heating chamber 14 is provided with a first air intake pipe 18 and a second air intake pipe 19, the second air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com