Method for cutting rare earth alloy with scroll saw and method for producing rare earth alloy plate

A wire saw and rare earth technology, which is applied in the manufacture of tools, metal sawing equipment, inductors/transformers/magnets, etc., can solve the problems of impracticability, wire breakage, and reduced cutting accuracy, and achieve sufficient and effective separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

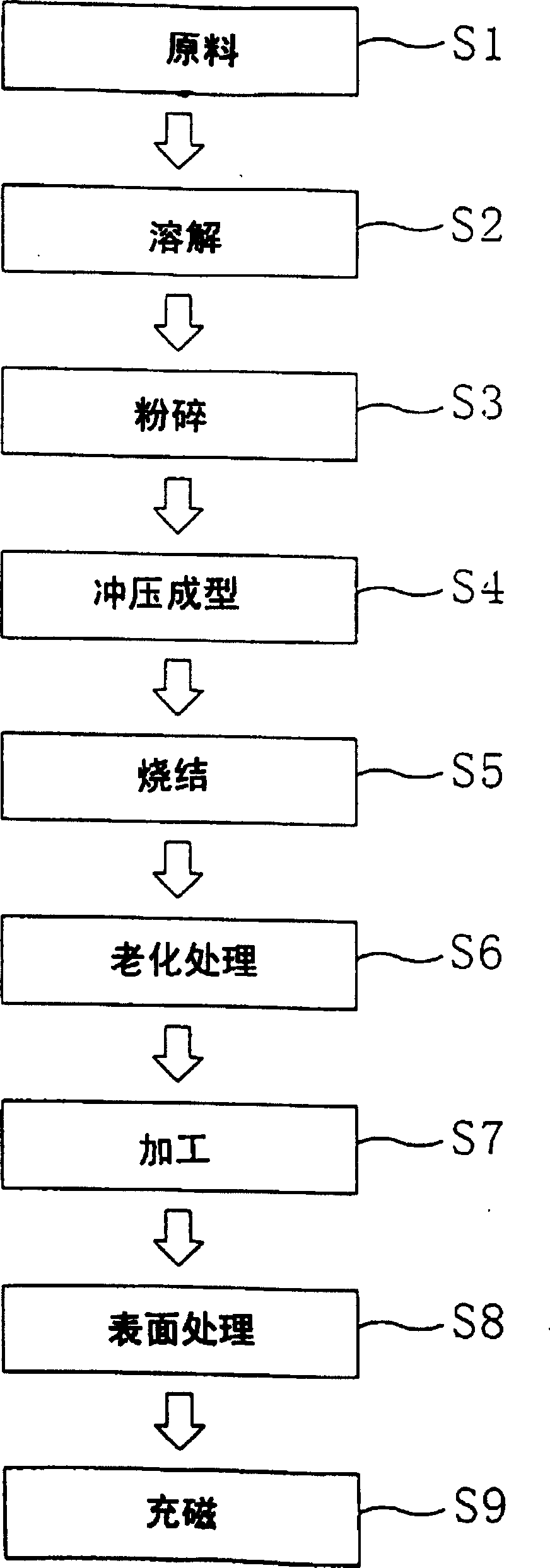

[0040] Next, an example of the method for producing the rare earth alloy sheet of the present invention will be described. In this embodiment, a ternary system compound Nd-Fe-B mainly composed of neodymium (Nd), iron (Fe) and boron (B) is used as a rare earth alloy, or Dy (dysprosium) is used to replace Nd- A compound in which a part of Nd in Fe-B is replaced with Co (cobalt) for a part of Fe. As we all know, Nd-Fe-B is the largest energy product over 320ks / m 3 Strong neodymium magnet material.

[0041] Refer below figure 1 The flow chart briefly illustrates the production method of the Nd-Fe-B blank. A method for producing a rare earth alloy as a magnet material is described in detail in, for example, US Patent No. 4,770,723.

[0042] First, in figure 1 After accurately weighing the raw materials according to the set composition ratio in step S1, the raw materials are melted in a vacuum or argon atmosphere high-frequency melting furnace in step S2. The molten raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com