A method for separating tellurium in crude selenium refining process

A refining process and crude selenium technology, applied in the metallurgical field, can solve the problems such as the quality of refined selenium powder cannot meet the requirements, the impurity removal effect is not good, etc., achieve good promotion value and economic benefits, shorten the production cycle, and increase the direct yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

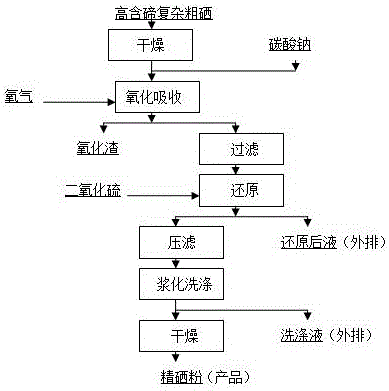

Method used

Image

Examples

Embodiment 1

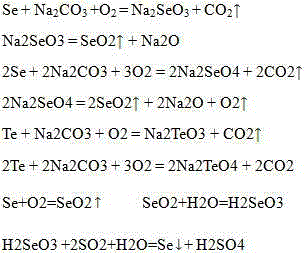

[0021] A method for separating tellurium in the refining process of high tellurium-containing complex crude selenium (alloy crude selenium), wherein the mass percentage content of tellurium as an impurity in the crude selenium is 3.56%, which comprises the following steps:

[0022] Step 1, weigh the 45% sodium carbonate powder of the impurity tellurium quality contained in the coarse selenium, add in the oxidation furnace after the sodium carbonate powder is uniformly mixed with the coarse selenium;

[0023] Step 2. Heating the oxidation furnace. When the temperature of the furnace rises to 100°C, feed oxygen, and the flow rate of oxygen is controlled at 15Nm 3 / h, when the temperature rises to 500°C, increase the oxygen flow rate to 25Nm 3 / h, the pressure in the oxidation furnace is -29Mpa, and at the same time replenish water in the absorption tank of the oxidation furnace in time to ensure that the negative pressure in the furnace is stable. The feeding time is 4.21h, the...

Embodiment 2

[0026] A method for separating tellurium during the refining process of high-tellurium-containing complex crude selenium (selenium material obtained by leaching of alloy blowing acid mud), wherein the mass percentage content of tellurium as an impurity in the crude selenium is 8.11%, which includes the following steps:

[0027] Step 1, weigh the 55% sodium carbonate powder of impurity tellurium quality contained in the coarse selenium, add in the oxidation furnace after the sodium carbonate powder is evenly mixed with the coarse selenium;

[0028] Step 2: Heating the oxidation furnace. When the temperature of the furnace rises to 100°C, feed oxygen, and the flow rate of oxygen is controlled at 20Nm 3 / h, when the temperature rises to 500°C, increase the oxygen flow rate to 25Nm 3 / h, the pressure in the oxidation furnace is -30Mpa, and at the same time replenish water in the absorption tank of the oxidation furnace in time to ensure that the negative pressure in the furnace is...

Embodiment 3

[0032] A method for separating tellurium in the refining process of high-tellurium-containing complex crude selenium (sedimented selenium slag), wherein the mass percent content of tellurium as an impurity in the crude selenium is 5.11%, which comprises the following steps:

[0033] Step 1, weighing 50% sodium carbonate powder of the impurity tellurium quality contained in the coarse selenium, adding the sodium carbonate powder and coarse selenium into the oxidation furnace after being uniformly mixed;

[0034] Step 2: Heating the oxidation furnace. When the temperature of the furnace rises to 100°C, feed oxygen, and the flow rate of oxygen is controlled at 18Nm3 / h. When the temperature rises to 500°C, increase the flow rate of oxygen to 25Nm3 / h. The pressure is -32Mpa. At the same time, water is replenished in the absorption tank of the oxidation furnace in time to ensure a stable negative pressure in the furnace. The temperature in the first section of the oxidation furnace i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com