Stain-proof fabric capable of preventing evaporative heat loss

A technology of evaporative heat and fabrics, which is applied in the field of textile fabrics and fabrics, can solve problems such as easy to get dirty, limited functions, airtightness, etc., and achieve the effects of preventing evaporative heat loss, good heat preservation effect, and good sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

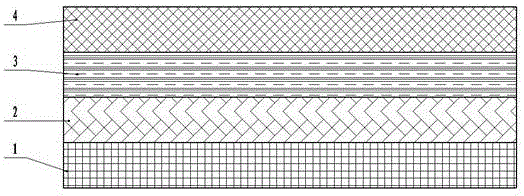

[0014] see figure 1 , an anti-fouling fabric for preventing evaporation heat loss, comprising an inner layer, the inner layer is provided with a breathable layer, an outer layer and an anti-fouling layer in sequence, and each layer is fixed by sewing; the inner layer includes a first warp yarn and a first Weft yarn, the first warp yarn is made of jute fiber, and the first weft yarn is made of holy hemp fiber; the air-permeable layer includes a second warp yarn and a second weft yarn, and the second warp yarn is made of acrylic fiber. The second weft yarn is made of polyester fiber; the outer layer includes a third warp yarn and a third weft yarn, the third warp yarn is made of bamboo fiber, and the third weft yarn is made of spandex fiber; the antifouling layer is Fluorine monomer waterborne polyurethane coating layer.

[0015] The back of the inner layer is provided with a lining fabric layer. The lining fabric layer is a composite fabric consisting of a lining, a barrier la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com