Wave dissipating prefabricated block

A technology of prefabricated blocks and bumps, applied in coastline protection and other directions, can solve the problems of poor stability of cement blocks and easy sliding, and achieve the effects of short construction time, enhanced connection strength, and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

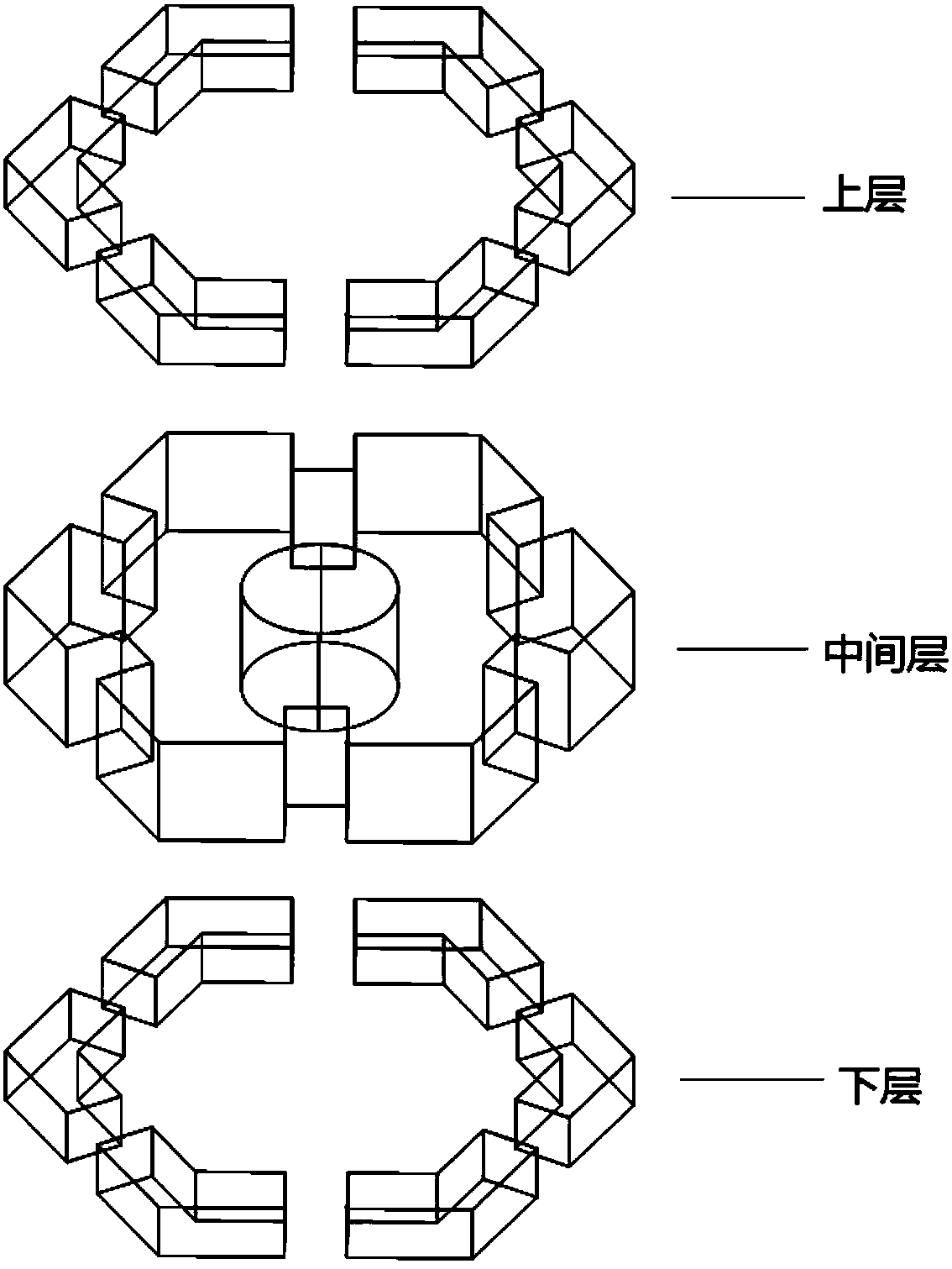

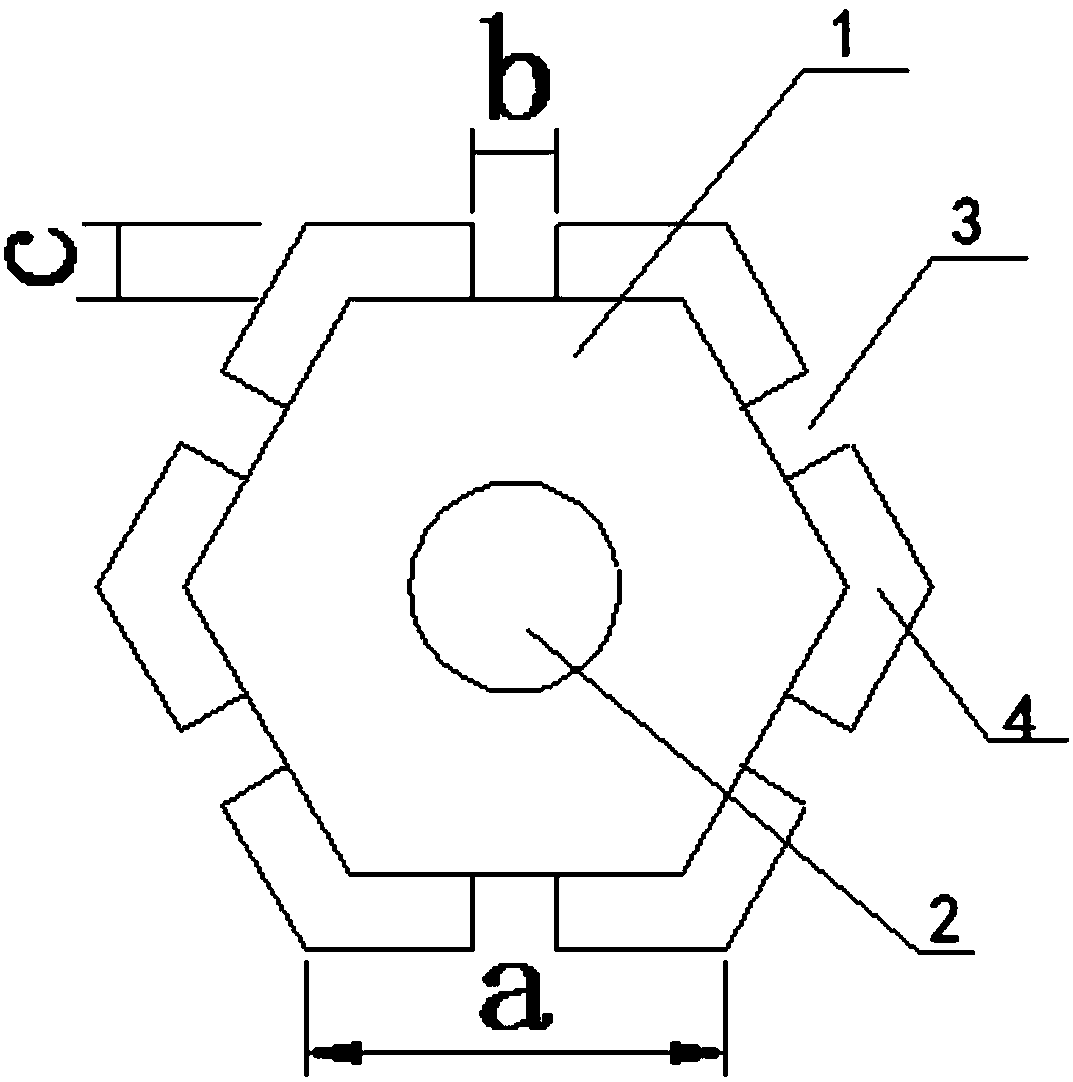

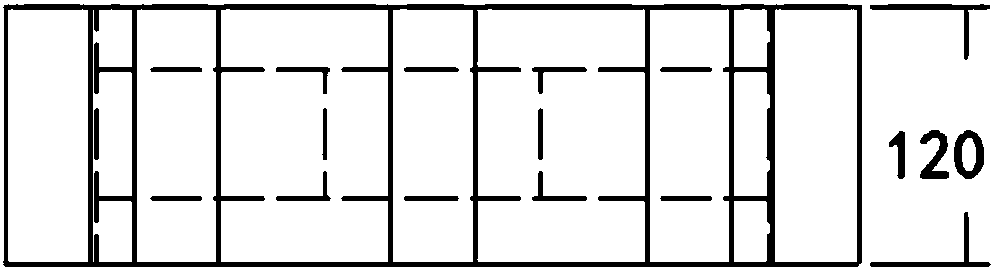

[0023] Such as Figure 1 to Figure 3 As shown, a prefabricated block for wave dissipation includes a prefabricated block body 1, the prefabricated block body 1 is a regular hexagon, and the height of the prefabricated block body 1 is 60mm. In order to ensure that the wave-dissipating prefabricated blocks cooperate with each other and do not cause extrusion protrusions due to insufficient gaps, the specifications of each wave-dissipating prefabricated block are uniform, and the length of each side of the prefabricated block body 1 is a, a 200mm. A through hole 2 is opened in the center of the prefabricated block body 1, the through hole 2 is a circular through hole, and the radius of the through hole 2 is 50mm. In order to effectively disch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com