Light distribution structure of light-emitting diode (LED) lamp

A technology for LED lamps and lamps, which is applied in the directions of light sources, light source fixing, and components of lighting devices, etc., can solve the problems of high risk, poor process stability, and enlarged waterproof area, and achieves reduction of light-emitting area, small light-emitting area, and heat dissipation. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0028] The technical scheme of concrete implementation of the present invention is:

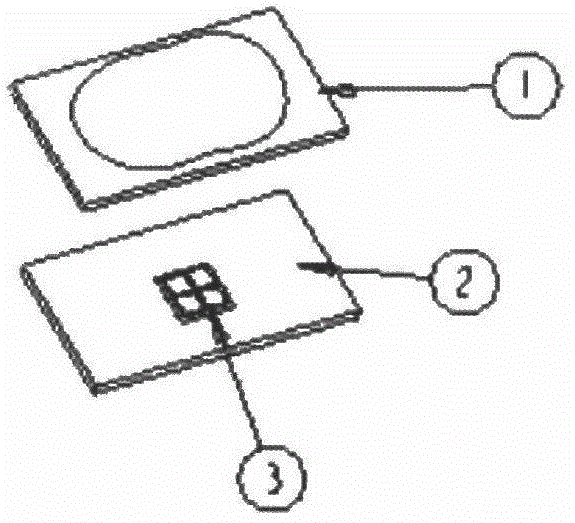

[0029] Such as figure 1 As shown, a light distribution structure of an LED lamp includes: a PCB aluminum substrate 2 welded with a lamp bead group 3, and a plastic lens 1 for covering the lamp bead group 3;

[0030] The lamp bead group 3 is composed of four medium-power 3030 double-crystal lamp beads, and the four lamp beads are distributed in a square shape;

[0031] The plastic lens 1 is provided with a convex surface cover for covering the lamp bead group 3;

[0032] The plastic lens 1 is made of UV-resistant PC material.

[0033] The inner cavity diameter of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com