Aircraft keel beam

An aircraft and keel technology, applied in the field of keel beams, can solve the problems of not allowing deformation and increasing stress, and achieve the effect of optimizing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

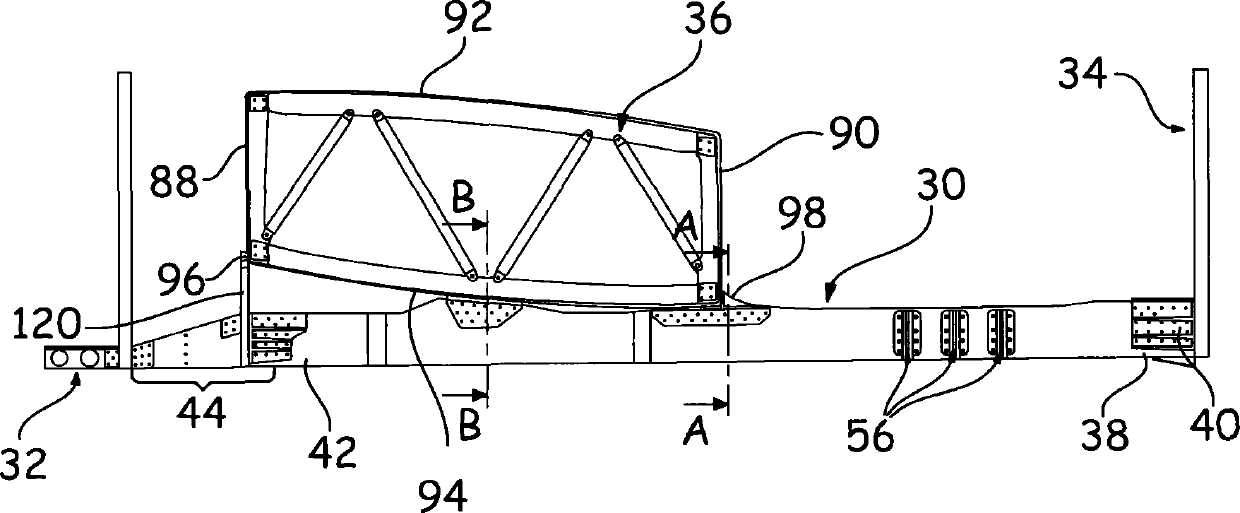

[0029] image 3 A keel beam 30 for connecting a front structure 32 and a rear structure 34 of the aircraft is shown. The keel beam 30 is connected to a center wing box 36 . The joist beam 30 includes a rear end 38 connected to the rear structure 34 by means of a splice plate 40 and a front end 42 connected to the front structure 32 by means of an assembly of stiffeners and splice plates 44 .

[0030] The keel beam 30 is made of composite material to reduce the onboard mass. Alternatively, the joist beams may be metallic and obtained by bending, extruding, pressure forming, explosion forming or the like.

[0031] According to the invention, the joist beam 30 comprises on the one hand a first U-shaped portion 46 , hereafter referred to as the body, having a horizontal bottom 48 and two solid side walls 50 , 50 ′, and on the other hand a second portion, referred to as the cover. Portion 52 , which together with body 46 defines a closed portion and includes opening 54 for acces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com