Titanium niobate/carbon composite electrode material and preparation method thereof

An electrode material and carbon composite technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low conductivity and low rate performance, and achieve the effects of improving conductivity, convenient operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] a. Weigh rutile titanium dioxide and niobium pentoxide according to the atomic ratio Ti:Nb=1:5.88, and then weigh a certain amount of citric acid, wherein the quality of citric acid is 5% of the total mass of carbon dioxide and niobium oxide, These three substances are placed in a ball mill tank, and ethanol is used as a dispersion medium, and ball milled on a ball mill at 600 rpm for 24 hours to fully mix the raw materials;

[0031] b. drying the mixture obtained in step a at 71° C. to obtain a precursor;

[0032] c. Calcining the precursor obtained in step b at 1300° C. for 52 hours under the protection of argon, and naturally cooling down to room temperature to obtain titanium niobate / carbon composite electrode material.

[0033] The experimental result of the titanium niobate / carbon composite electrode material that embodiment 1 prepares is as follows Figure 1-Figure 4 shown.

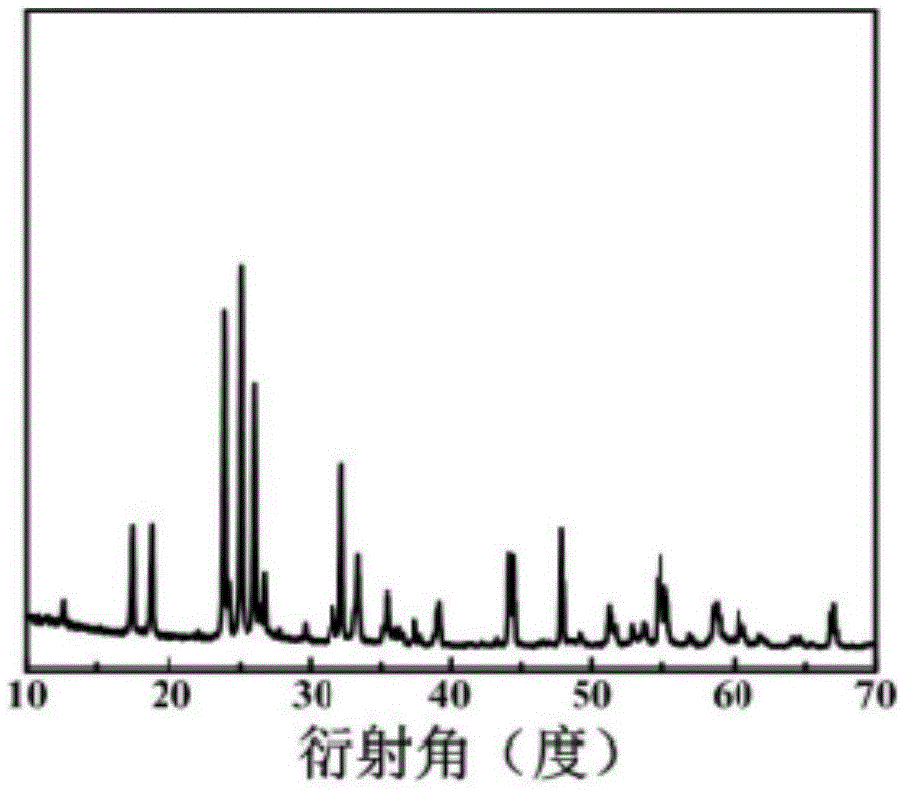

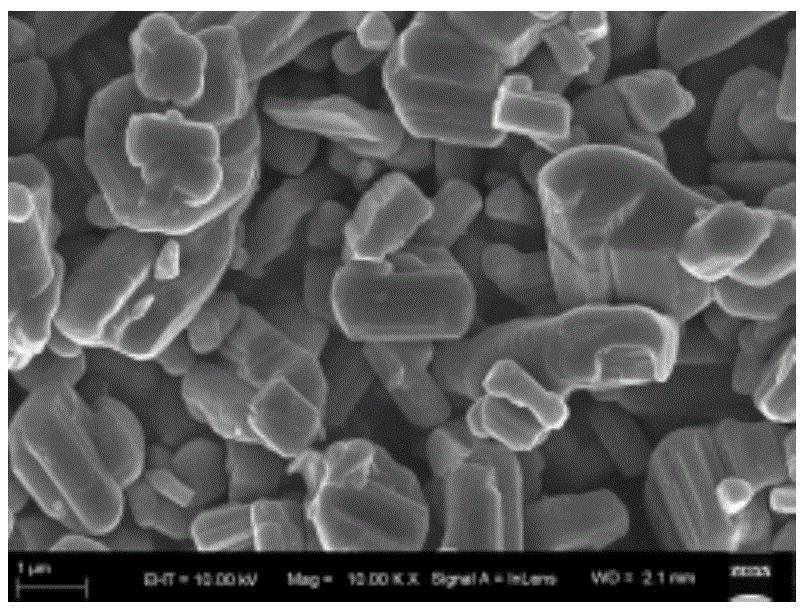

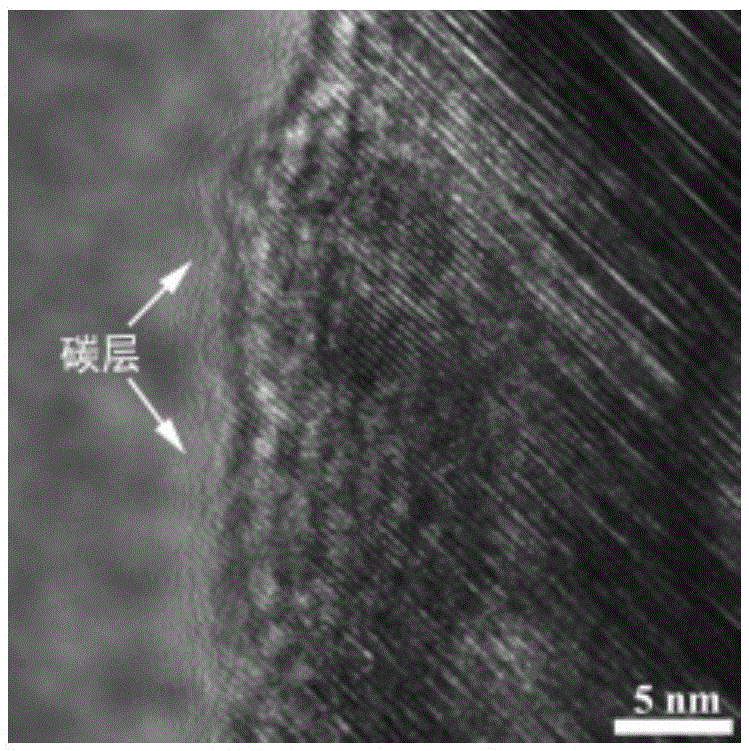

[0034] figure 1 The XRD figure of the titanium niobate / carbon composite electrode mat...

Embodiment 2

[0039] a, take by weighing rutile type titanium dioxide and niobium dioxide by atomic ratio Ti:Nb=1:6.35, then take by weighing a certain amount of acetylene black, wherein, the quality of acetylene black is 2% of the total mass of carbon dioxide and niobium oxide, will These three kinds of materials are placed in the ball mill tank, with ethanol as the dispersion medium, on the ball mill with 280 rpm ball mill for 19 hours, the raw materials are fully mixed;

[0040] b. drying the mixture obtained in step a at 78° C. to obtain a precursor;

[0041] c. Calcining the precursor obtained in step b at 950° C. for 35 hours under the protection of nitrogen, and naturally cooling down to room temperature to obtain the titanium niobate / carbon composite electrode material.

Embodiment 3

[0043] a. Weigh anatase titanium dioxide and NiO3 according to the atomic ratio Ti:Nb=1:6.16, and then weigh a certain amount of graphite, wherein the mass of graphite is 13% of the total mass of carbon dioxide and niobium oxide, These three substances are placed in a ball mill tank, and ethanol is used as a dispersion medium, and ball milled on a ball mill at 320 rpm for 20 hours to fully mix the raw materials;

[0044] b. drying the mixture obtained in step a at 90° C. to obtain a precursor;

[0045] c. Calcining the precursor obtained in step b at 1190° C. for 39 hours under the protection of nitrogen, and naturally cooling down to room temperature to obtain titanium niobate / carbon composite electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com