Powder metallurgy tantalum powder and/or niobium powder and preparing method thereof

A technology of powder metallurgy and niobium powder, which is applied in the field of tantalum powder and/or niobium powder and its preparation, and can solve problems such as serious environmental pollution, difficulty in breaking sintered agglomerates, and complex equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

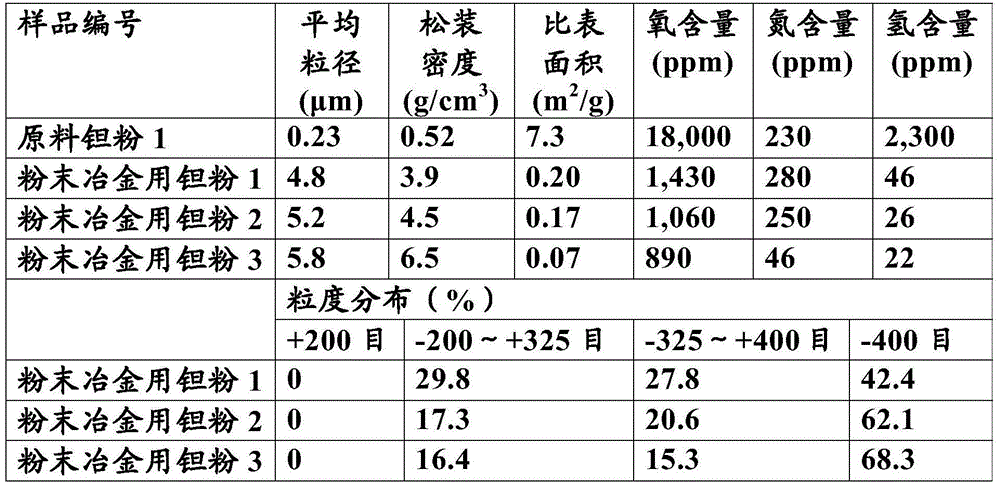

[0059] Take the raw material tantalum powder 1 totaling 200kg, divide it into 30 trays in a tantalum crucible, put it on the material rack, send it into the heat treatment furnace, start the evacuation system, and the vacuum degree is lower than 3.0×10 -2 After Pa, power is sent to heat, the sintering temperature is 1500°C, and the sintering time is 3 hours. After sintering, the temperature is lowered, and when the detection temperature is lower than 50°C, air is slowly introduced into the chamber where the materials of the sintering furnace are located for passivation, and a sintered block is obtained after being discharged from the furnace. After putting the sintered block into the hydrogenation container, firstly discharge the air in the container through evacuation, then pass 0.5Mpa hydrogen with a purity of 99.995% into the container as a protective gas, and then heat the sintered block to a high temperature of 800-950°C , keep warm for 3 hours, then cut off the power to ...

Embodiment 2

[0061] Take raw material tantalum powder 1 totaling 200kg, divide it into 30 trays with graphite crucibles, heat treatment and sintering temperature is 1500°C, and sintering time is 10 hours, other conditions are the same as in Example 1. The finally obtained tantalum powder for powder metallurgy is numbered as tantalum powder for powder metallurgy 2, and its physical properties and chemical impurities are analyzed. The analysis results are shown in Table 2.

Embodiment 3

[0063] Get raw material tantalum powder 1 and add up to 200kg, divide it into 30 trays with graphite crucibles, heat treatment sintering temperature is 2100 ℃, and sintering time is 10 hours, other conditions are carried out heat treatment sintering, hydrogenation pulverization according to the condition of embodiment 1, analysis Oxygen and hydrogen content in tantalum hydride powder, analysis results: oxygen content is 13,000ppm, hydrogen content is 5,600ppm, 2.0 times the stoichiometric amount of metal magnesium required is evenly mixed into the tantalum hydride powder, converted according to the weight of tantalum hydride powder, The metal magnesium is 4.0% of the weight of tantalum hydride powder, and other conditions are carried out according to the conditions of Example 1 for dehydrogenation and oxygen reduction, pickling and impurity removal. The tantalum powder for powder metallurgy was coded as tantalum powder for powder metallurgy 3, and its physical properties and ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com