Highly impact-resistant steel pipe and method for producing the same

a technology of high impact resistance and steel pipes, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems that most electric-resistance-welded steel pipes tend to undergo deterioration of strength and toughness, and achieve low yield ratio, high ts, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

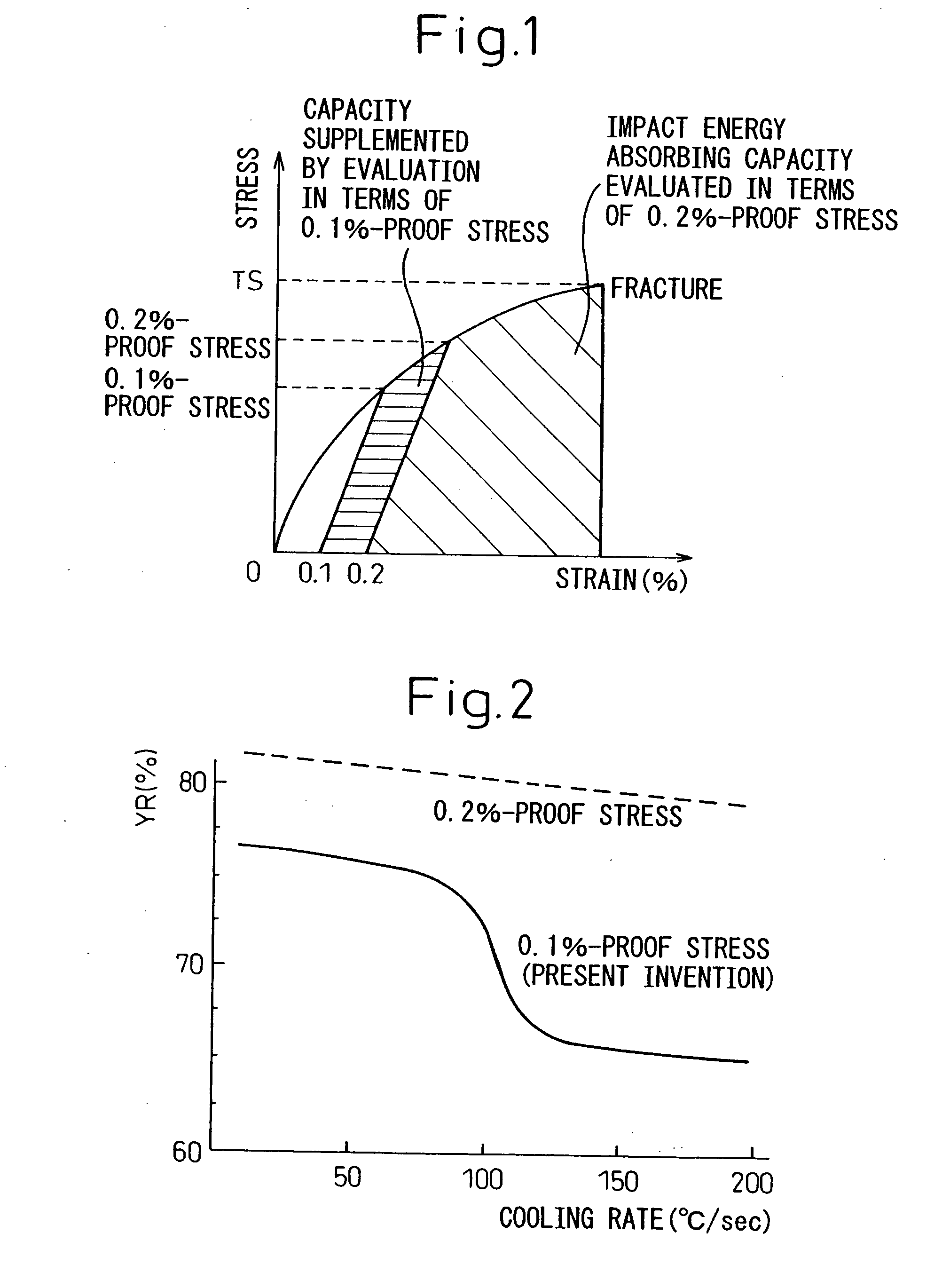

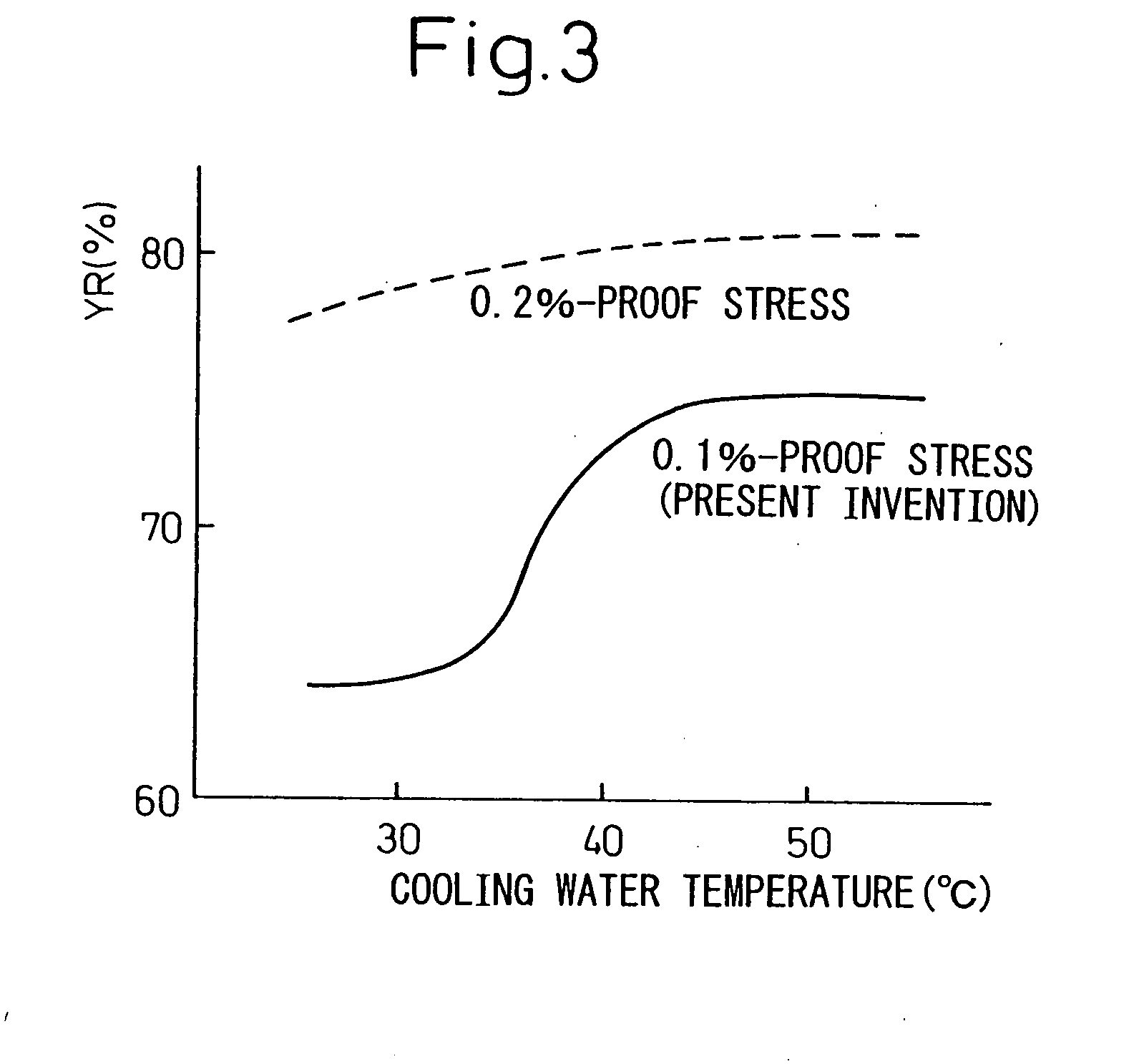

[0042] Electric-resistance-welded steel pipes comprising the steels having various compositions shown in Table 1 were produced, heated with induction heating by moving at a constant speed on a conveyer and passing through wire coils, and then rapidly cooled to an ordinary temperature with an adjacent water quenching device. The cooling rates and cooling water temperatures are shown Table 2. The 0.1%-proof stresses and rupture strengths were measured by subjecting cut-out test pieces to a tensile tester. Further, the test pieces after being subjected to the tensile tests were observed with a transmission electron microscope. The resulting dislocation densities are also shown in Table 2.

TABLE 1InventiveInventiveInventiveInventiveInventiveInventiveInventiveInventiveexample 1example 2example 3example 4example 5example 6example 7example 8C (%)0.210.240.280.280.300.300.350.30Si (%)0.220.230.210.210.200.200.210.20Mn (%)1.411.431.411.411.441.441.401.00P (%)0.0210.0210.0180.0180.0160.0160....

example 2

[0045] Electric-resistance-welded steel pipes having various compositions shown in Table 3 were produced and the tensile strength, the ratio of the strength of a welded portion to that of a body portion, the occurrence of cracks at low temperature impact bending, and others of each of the steel pipes were measured. The results are shown in Table 3. The value of α=Si−Mn / 8 and the prior austenite grain size number of each of the steel pipes are also shown in Table 3. The invention examples 9 to 13 and the comparative examples 1 to 3 are the examples of round-shaped electric-resistance-welded steel pipes and the invention examples 14 and 15 and the comparative example 4 are the examples of square-shaped electric-resistance-welded steel pipes having quadratic sectional shapes.

TABLE 3InventiveInventiveInventiveInventiveInventiveInventiveInventiveCompara-Compara-Compara-Compara-exampleexampleexampleexampleexampleexampleexampletivetivetivetive9101112131415example 1example 2example 3examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com