Aging-resistant bake-hardened steel plate and galvanized plate and production method of aging-resistant bake-hardened steel plate

A technology of bake hardening and production method, which is applied in hot-dip plating process, coating, metal material coating process, etc., which can solve the problem of ensuring the stability of bake hardenability and aging resistance of the coil, and increase the control of other process links Difficulty, unfavorable secondary processing brittleness, etc., to achieve good market application prospects, avoid secondary processing brittleness, good bake hardenability and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

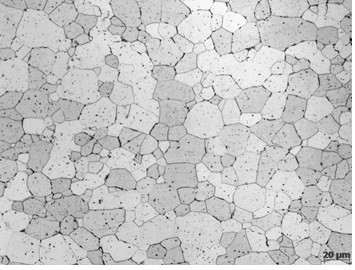

Image

Examples

Embodiment 1-8

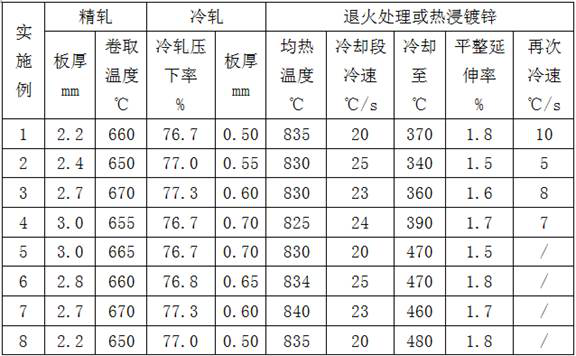

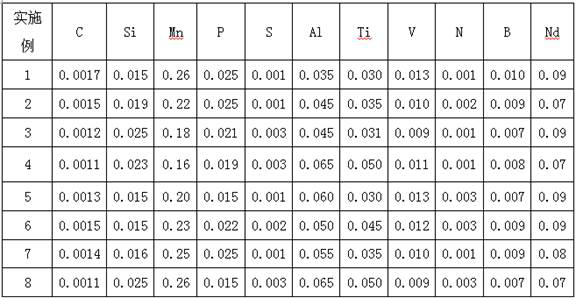

[0032] Embodiments 1-8: The aging-resistant bake-hardening steel sheet and its galvanized sheet and the production method adopt the following process, wherein the product of Embodiment 1-4 is a cold-rolled annealed steel sheet, and the product of Embodiment 5-8 is a galvanized sheet.

[0033] (1) Finish rolling process: the steel billet is heated to the austenite single-phase region for direct finish rolling, the thickness of the rolled plate is controlled at 2.2-3.0 mm, and the coiling temperature is controlled at 650-670 °C.

[0034] (2) Cold-rolling process: cold-rolled steel coils or steel plates with a thickness of 0.50-0.70mm are obtained through cold-rolling reduction of 76.7-77.3%.

[0035] (3) Annealing treatment process: Examples 1-4 adopt annealing treatment to obtain cold-rolled annealed steel plates; the annealing process is: the steel coil or steel plate obtained in step (2) is continuously annealed at a soaking temperature of 825-835 °C, and the cooling section i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com