Preheating method for improving bake-hardening performance and forming performance of 6022 aluminum alloy

A technology of preheating and baking hardening, which is applied in the field of aluminum alloy heat treatment, can solve the problems of reducing formability, solute atom impoverishment, increasing stamping springback, etc., and achieves improvement of baking hardenability, suppression of natural aging, and suppression of adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

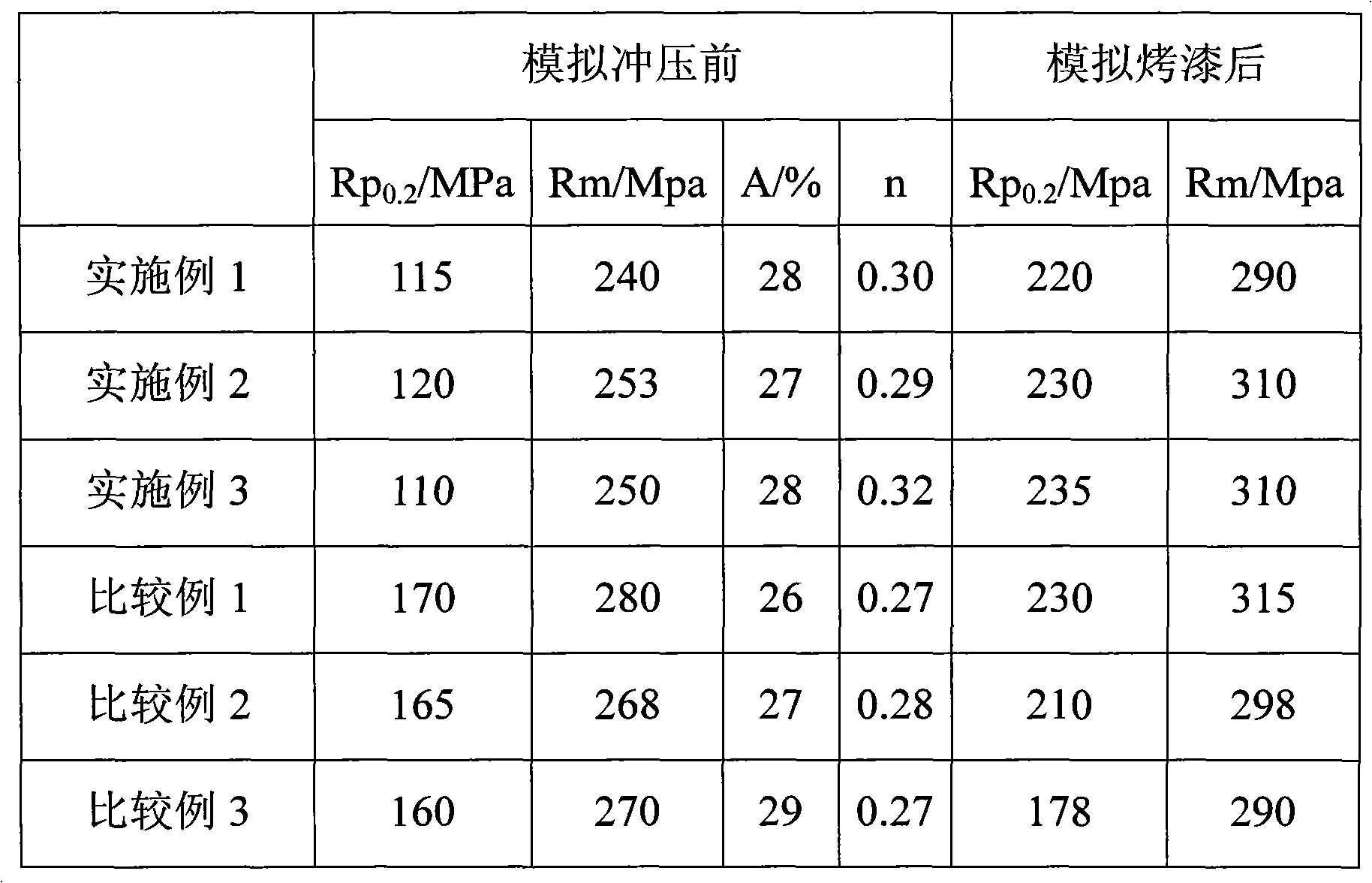

Embodiment 1

[0016] The 6022 aluminum alloy sheet was solid-dissolved at 530°C for 20 minutes, and then quenched in water. After standing at room temperature for 1 day, carry out pre-aging treatment: the treatment temperature is 180°C, the time is 60 seconds, and then after standing at room temperature for 1 month, carry out simulated stamping and baking paint treatment (2% pre-deformation + 175°C×30min heat treatment ).

Embodiment 2

[0018] The 6022 aluminum alloy sheet was solid-dissolved at 550°C for 10 minutes and quenched in water. After standing at room temperature for 20 hours, carry out pre-aging treatment: the treatment temperature is 250 ° C, the time is 20 seconds, and then after standing at room temperature for 1 month, carry out simulated stamping and baking paint treatment (2% pre-deformation + 175 ° C × 30 min heat treatment).

Embodiment 3

[0020] The 6022 aluminum alloy sheet was solid-dissolved at 555°C for 15 minutes, and then quenched in water. After standing at room temperature for 5 hours, carry out pre-aging treatment: the treatment temperature is 200°C, the time is 30 seconds, and then after standing at room temperature for 1 month, carry out simulated stamping and baking paint treatment (2% pre-deformation + 175°C×30min heat treatment).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com