Hot-dip galvanized steel sheet with superior bake hardenability and aging resistance, and manufacturing method thereof

A bake-hardening and hot-dip galvanizing technology, applied in hot-dip galvanizing process, manufacturing tools, heat treatment furnaces, etc., can solve the problems of increased manufacturing cost and difficulty in ensuring the quality of electroplating, and achieve excellent bake hardenability and aging resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] Hereinafter, the present invention will be described in more detail by way of examples. However, the following examples only illustrate the present invention in more detail and do not limit the scope of the present invention.

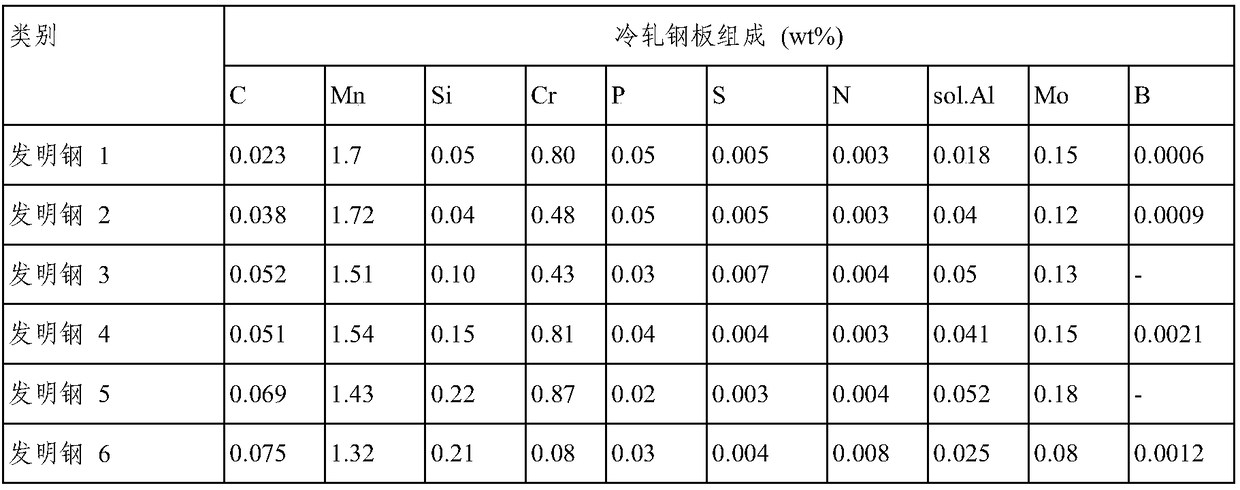

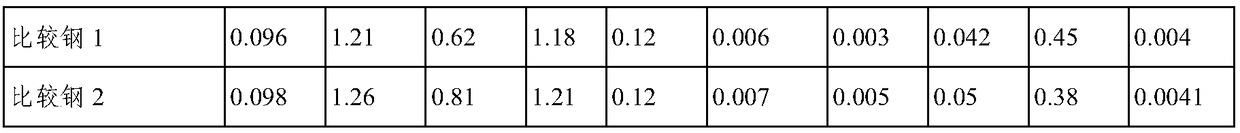

[0082] After preparing slabs having the alloy compositions shown in Table 1 below, hot-dip galvanized steel sheets (GI steel sheets) or galvannealed steel sheets (GA steel sheets) were prepared using the manufacturing method described in Table 2 below. For reference, Inventive Steels 1, 2, 4, and 5 and Comparative Examples 1 and 2 correspond to alloyed hot-dip galvanized steel sheets, and Inventive Steels 3 and 6 correspond to hot-dip galvanized steel sheets in Table 1 below. At the same time, during the preparation of each sample, the end temperature of the first cooling was constantly set to 650°C, then the end temperature of the second cooling was constantly set to 560°C, and the end temperature of the third cooling was constant The ground is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com