High-strength steel plate

一种高强度钢板、抗拉强度的技术,应用在炉子类型、炉、热处理炉等方向,能够解决烘烤硬化量预应变依赖性小、烘烤硬化性高、烘烤硬化量大等问题,达到烘烤硬化性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

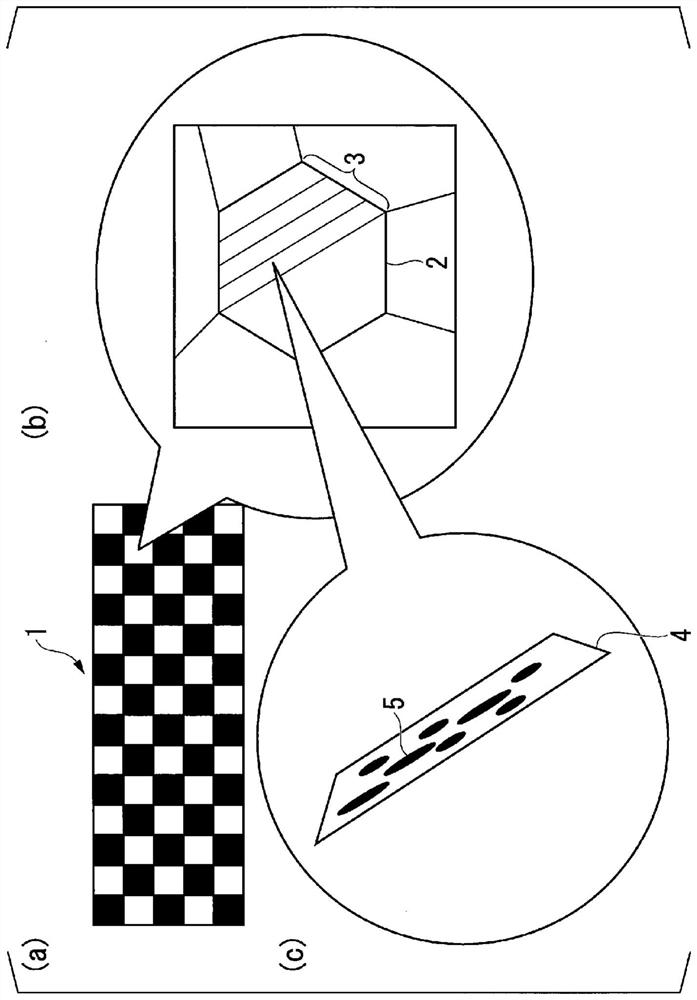

Image

Examples

Embodiment 1

[0163]Next, an embodiment of the present invention will be described. The conditions in the examples are an example of conditions used to confirm the practicability and effects of the present invention, and the present invention is not limited to this example of conditions. The present invention can adopt various conditions as long as it does not deviate from the gist of the present invention and achieves the purpose of the present invention.

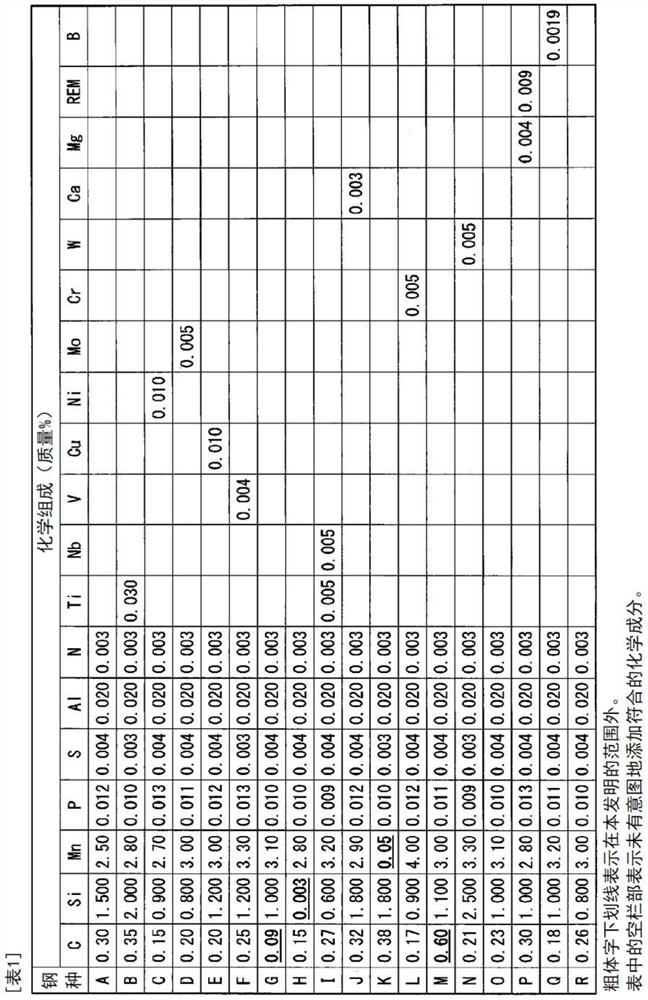

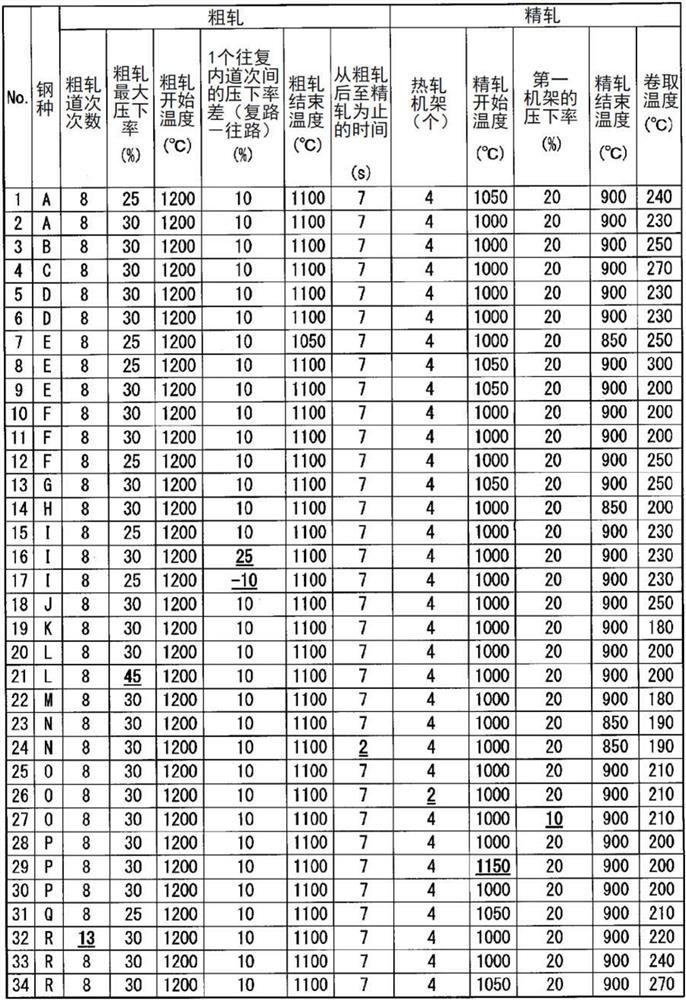

[0164]A slab having the chemical composition shown in Table 1 was produced. After the slab was heated at 1300°C for 1 hour, rough rolling and finish rolling were performed under the conditions shown in Table 2 to obtain a hot-rolled steel sheet. After that, the hot-rolled steel sheet was pickled, and cold-rolled at the reduction ratio shown in Table 2 to obtain a cold-rolled steel sheet. Next, annealing and heat treatment were performed under the conditions shown in Table 2. In addition, each temperature shown in Table 2 is the surface temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com