Steel sheet excellent in bake hardenability and corrosion resistance and method for producing the same

一种烘烤硬化、耐蚀性的技术,应用在制造工具、炉、热处理设备等方向,能够解决制造成本增加、难以确保镀覆质量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

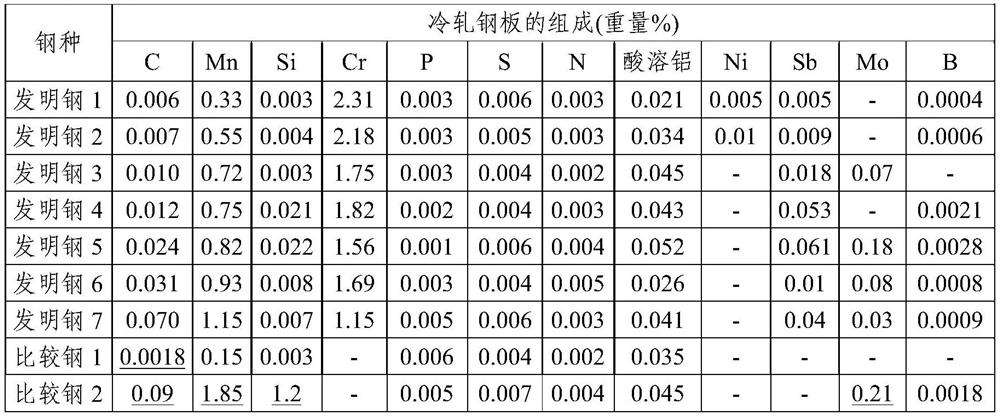

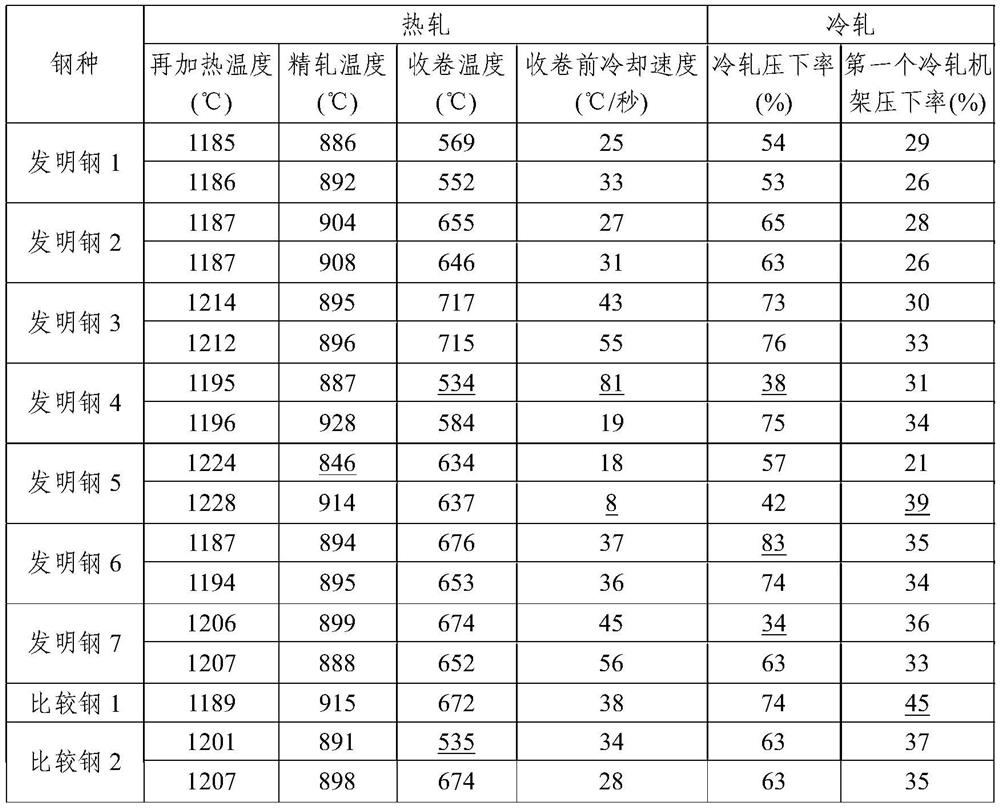

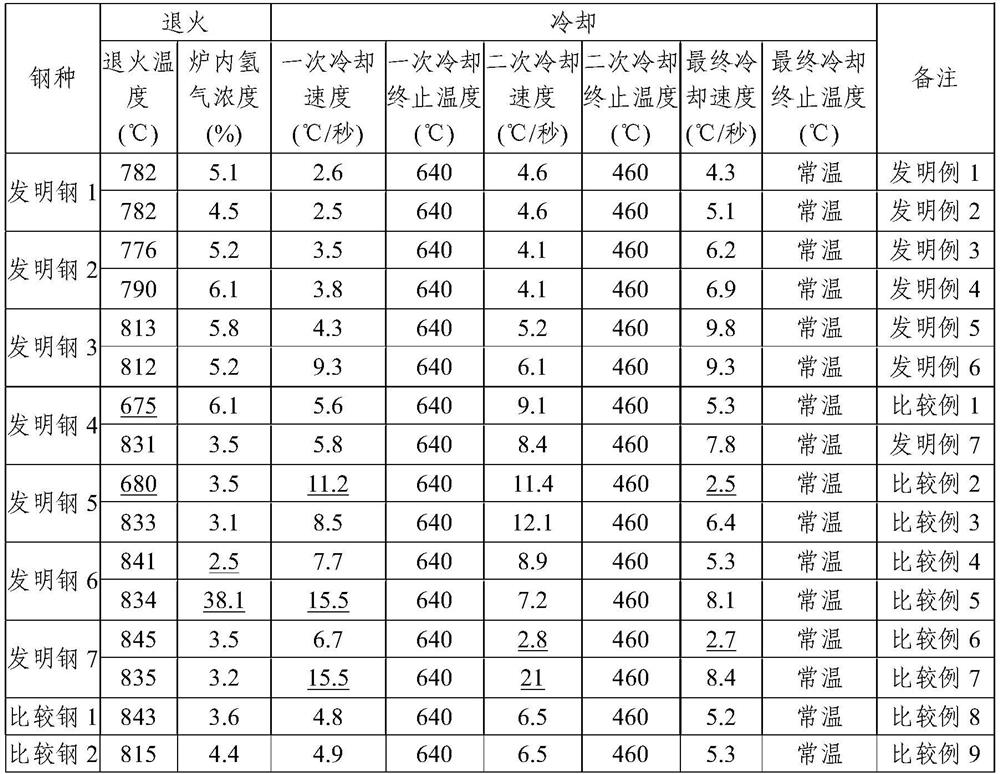

[0150] A billet having an alloy composition described in Table 1 below was prepared, and then a hot-dip galvanized steel sheet (GI steel sheet) or an alloyed hot-dip galvanized steel sheet (GA steel sheet) was manufactured using the manufacturing process described in Table 2 and Table 3 below. At this time, the hot-dip galvanizing is performed using a conventional hot-dip galvanizing bath, and the alloying heat treatment is also performed under normal conditions (500-540° C.).

[0151] For reference, in Table 1 below, Invention Steels 1, 2, 4, and 5 and Comparative Steels 1 and 2 correspond to alloyed hot-dip galvanized steel sheets, and Invention Steels 3, 6, and 7 correspond to hot-dip galvanized steel sheets. Comparative steel 1 is BH steel using conventional ultra-low carbon steel, and Comparative steel 2 is high carbon DP steel series steel.

[0152] The microstructures of the respective plated steel sheets manufactured as described above were observed and their physical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| longitudinal tensile yield strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| longitudinal tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com