Zinc-based plated steel sheet having excellent room temperature aging resistance and bake hardenability, and method for producing same

A baking hardening and time-sensitive technology, which is applied in chemical instruments and methods, manufacturing tools, hot-dip plating processes, etc., can solve the problems of increased manufacturing costs and difficulty in ensuring the quality of plating, and achieves excellent abnormal temperature resistance and aging resistance, excellent The effect of bake hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

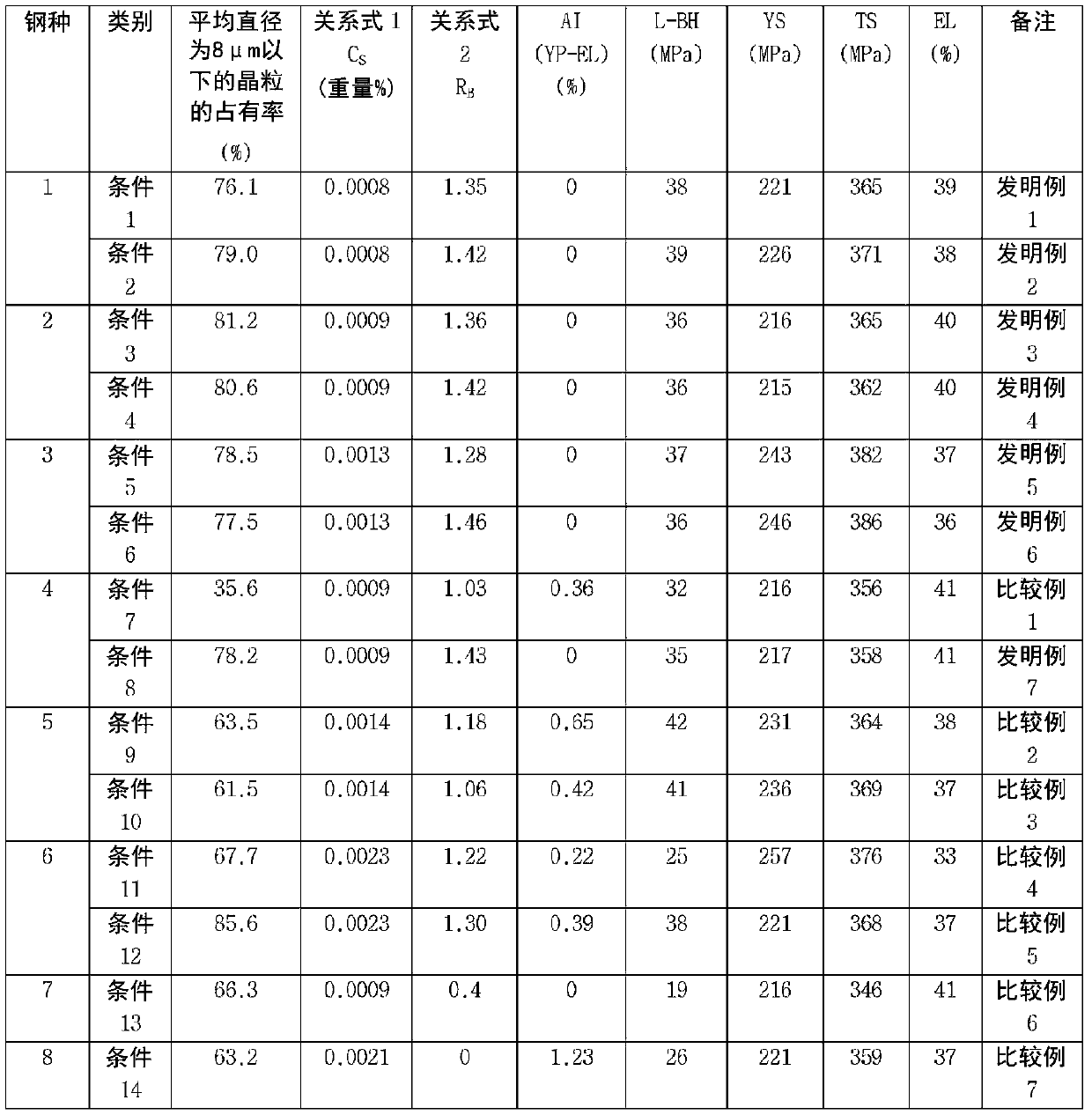

[0132] Hereinafter, the present invention will be described more specifically by way of examples. However, it should be noted that the following examples are only for illustrating the present invention and are not intended to limit the scope of rights of the present invention.

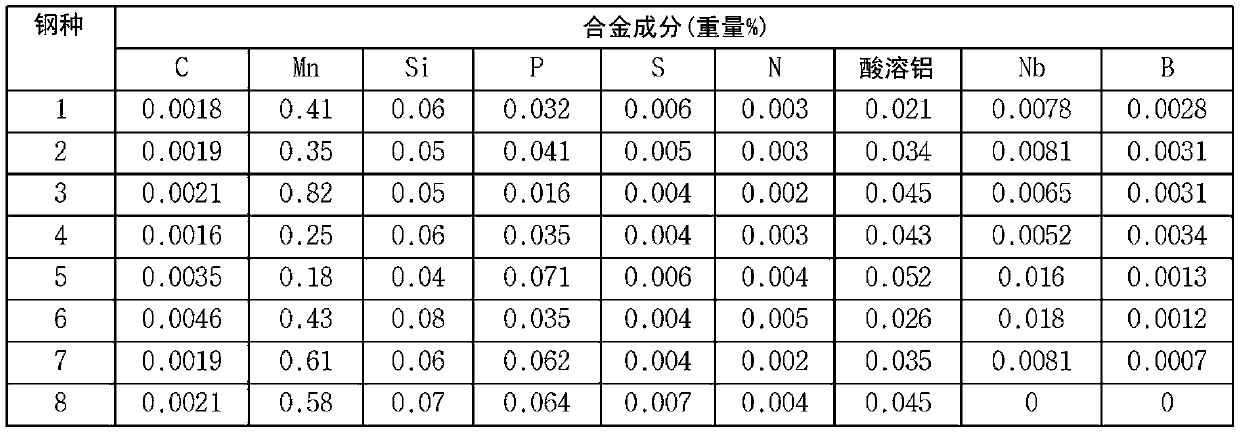

[0133] Steel slabs having the alloy compositions described in Table 1 below were manufactured, and zinc-based plated steel sheet test pieces were manufactured by the manufacturing process described in Table 2 below. For reference, steel grades 1, 2, 4, and 5 in Table 1 below belong to alloyed hot-dip galvanized steel sheets (GA steel sheets), and steel grades 3 and 6 belong to hot-dip galvanized steel sheets. Steel grades 7 and 8 represent BH steels using conventional ultra-low carbon steels.

[0134] [Table 1]

[0135]

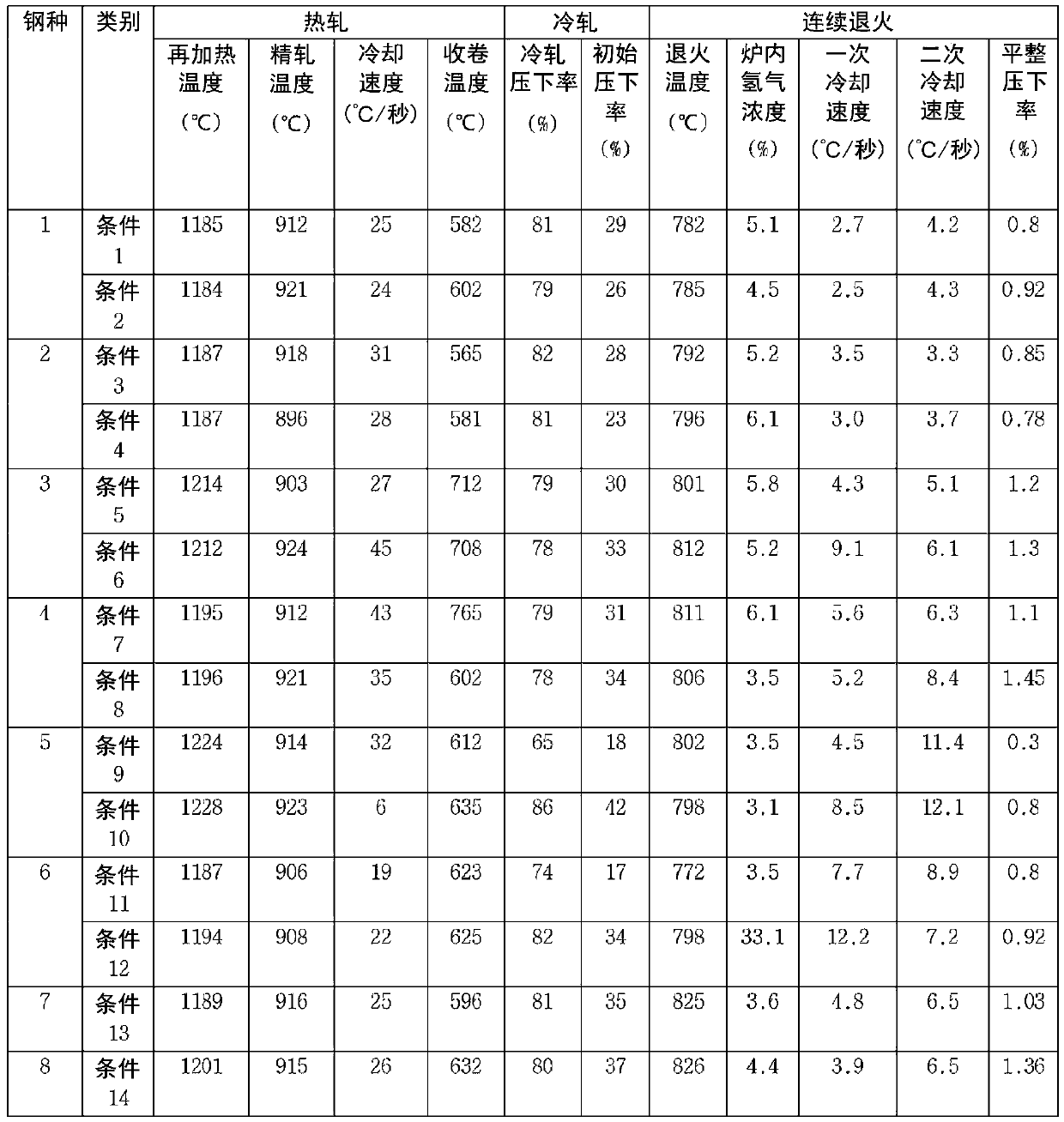

[0136] [Table 2]

[0137]

[0138]Using slabs having the compositions in Table 1, zinc-based alloy-plated steel sheet test pieces were produced under the conditions in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardening | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com