Thermal treatment method for improving bake-hardening performance and natural aging stability of 6xxx-series aluminum alloys

A heat treatment method and bake hardening technology, applied in the field of aluminum alloy processing, can solve the problems of good aging stability, time-consuming, low production efficiency, etc., and achieve the effects of improving bake hardening performance, reducing energy consumption, and long transfer time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

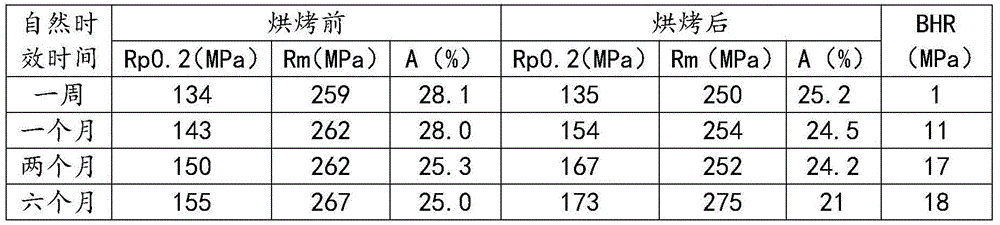

[0026] After the 6016 aluminum alloy ingot is homogenized, it is hot-rolled and cold-rolled to a thin plate of 1.0mm; the thin plate is rapidly water-quenched to room temperature within 20 minutes after solution treatment at 535°C / 5min, and enters the air-cushion furnace at a temperature of 50°C Insulation, heat preservation for 1min, air cooling to below 40°C, and then natural aging for one week, one month, two months, six months, then 175°C / 30min baking experiment, the mechanical properties of the samples before and after baking are shown in Table 1 Show.

[0027] Table 1 Bake hardening properties of pre-aged and air-cooled samples at 50℃

[0028]

[0029] Note: Rp0.2 is yield strength, Rm is tensile strength, A is elongation, BHR is bake hardening value (difference of yield strength before and after baking), the same below.

Embodiment 2

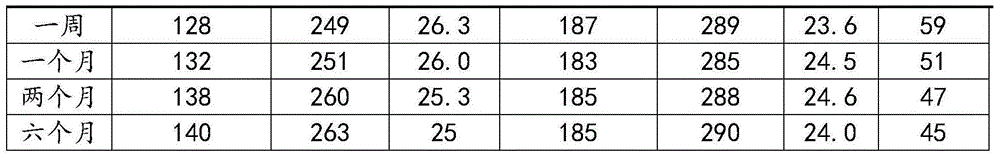

[0031] After the 6016 aluminum alloy ingot is homogenized, it is hot-rolled and cold-rolled to a thin plate of 1.0mm; the thin plate is rapidly water-quenched to room temperature within 20 minutes after solution treatment at 535°C / 5min, and enters the air-cushion furnace at a temperature of 70°C Insulation, keep the temperature for 1min and then cool down to below 40°C, the cooling rate is 20°C / h, then after natural aging for one week, one month, two months, and six months, conduct a baking experiment at 175°C / 30min, the mechanical properties of the sample before and after baking The performance is shown in Table 2.

[0032] Table 2 Bake hardening properties of samples pre-aged at 70°C with a cooling rate of 20°C / h

[0033]

[0034]

Embodiment 3

[0036] After the 6016 aluminum alloy ingot is homogenized, it is hot-rolled and cold-rolled to a thin plate of 1.0mm; the thin plate is rapidly water-quenched to room temperature and within 20 minutes after solution treatment at 535°C×5min, and then enters an air-cushion furnace at a temperature of 80°C Insulation, heat preservation for 1min and then lower the temperature to below 40°C with a cooling rate of 20°C / h, then natural aging for one week, one month, two months, and six months, then perform a baking test at 175°C / 30min, the samples before and after baking The mechanical properties are shown in Table 3.

[0037]Table 3 Bake hardening properties of samples pre-aged at 80°C with a cooling rate of 20°C / h

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com