Machining method of 180BH cold-rolled baked hardened high-strength steel for automobiles

A baking hardening and processing method technology, which is applied in the field of advanced high-strength steel for automobiles and metallurgical materials, can solve environmental pollution, traffic congestion and other problems, and achieve the effect of stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The chemical composition (mass fraction / %) of this embodiment is as follows: C 0.0019; Si 0.004; Mn 0.196; P 0.040; S 0.008; Als 0.029; Nb 0.012; Cr 0.065;

[0054] In this embodiment, the heating temperature of the hot-rolled slab is 1180° C., the finish rolling temperature is 900° C., the coiling temperature is 700° C.; the cold rolling reduction is 85%.

[0055] The continuous annealing process of this embodiment is as follows: hold at 850°C for 80 minutes; cool with the furnace to 730°C, and rapidly cool to 400°C at a cooling rate of 30°C / s, hold for 2 hours, and then cool with the furnace to room temperature.

[0056] The performance index of the present embodiment is as follows: Yield strength 190MPa; Tensile strength 330MPa; Elongation 42%; 90 value 0.21; r 90 Value 2.4; BH 2 Value 55.

Embodiment 2

[0058] The chemical composition (mass fraction / %) of this embodiment is as follows: C 0.0015; Si 0.001; Mn 0.18; P 0.035; S 0.005; Als 0.02; Nb 0.015; Cr 0.072;

[0059] In this embodiment, the heating temperature of the hot-rolled slab is 1210° C., the finish rolling temperature is 900° C., the coiling temperature is 710° C.; the cold rolling reduction is 80%.

[0060] The continuous annealing process of the present invention is as follows: heat preservation at 840°C for 90 minutes; cooling to 720°C with the furnace, and rapid cooling to 400°C at a cooling rate of 35°C / s, heat preservation for 3 hours, and cooling to room temperature with the furnace.

[0061] The performance index of the present embodiment is as follows: yield strength 205MPa; Tensile strength 325MPa; Elongation 41%; n 90 value 0.23; r 90 Value 1.88; BH 2 Value 35.

Embodiment 3

[0063] The chemical composition (mass fraction / %) of this embodiment is as follows: C 0.0025; Si 0.012; Mn 0.22; P 0.045; S 0.012; Als 0.0373; Nb 0.017; Cr 0.089;

[0064] In this embodiment, the heating temperature of the hot-rolled slab is 1190° C., the finish rolling temperature is 900° C., the coiling temperature is 690° C.; the cold rolling reduction is 90%.

[0065] The continuous annealing process of the present invention is as follows: heat preservation at 860°C for 70 minutes; cooling to 740°C with the furnace, and rapid cooling to 400°C at a cooling rate of 40°C / s, heat preservation for 2 hours, and cooling to room temperature with the furnace.

[0066] The performance index of the present embodiment is as follows: yield strength 215MPa; Tensile strength 348MPa; Elongation 45.5%; n 90 value 0.24; r 90 Value 2.94; BH 2 Value 48.

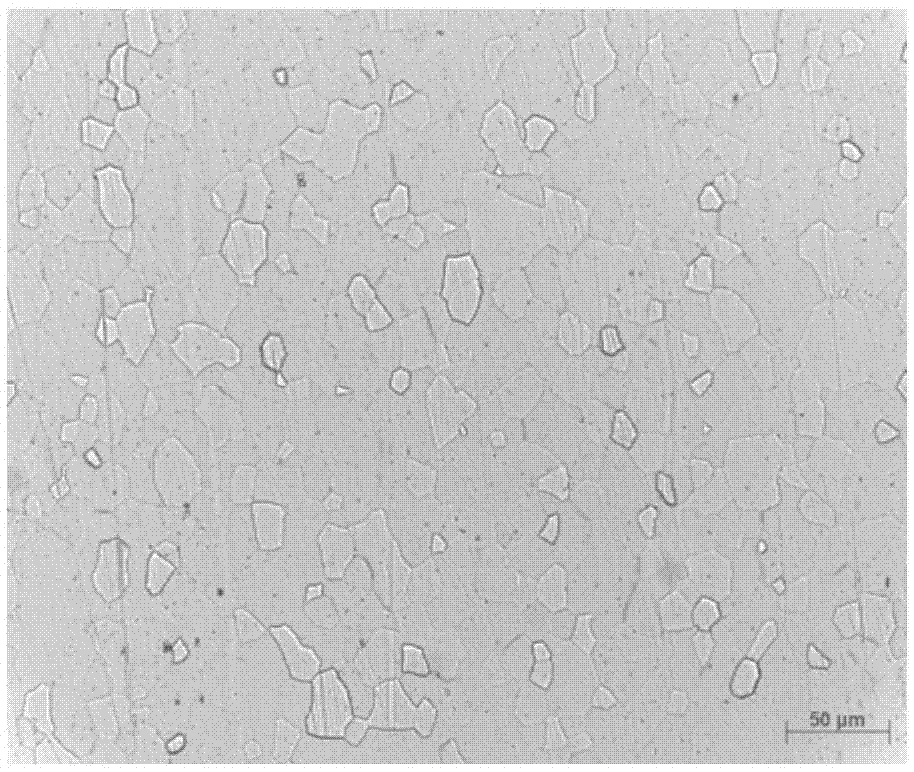

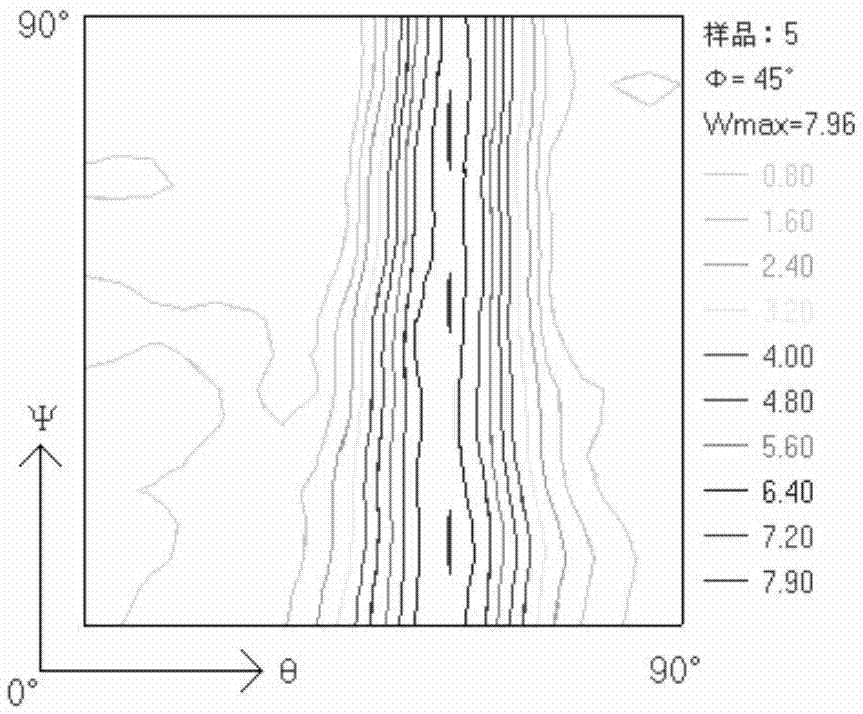

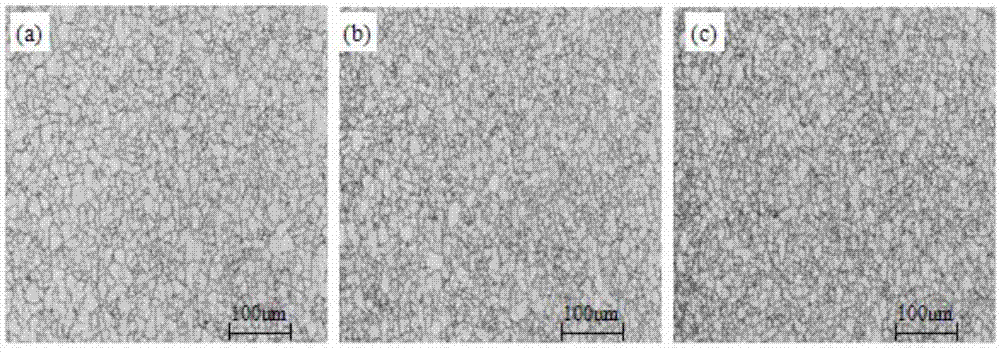

[0067] Such as figure 1 As shown in Table 1, the finished structure of cold-rolled bake-hardening high-strength high-strength steel 180...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com