High carbon steel wires excellent in spinnability and method for producing same

A high carbon steel wire, wire drawing technology, applied in the direction of metal rolling, etc., can solve the problem that the drawability of high carbon steel wire is not good enough, there is no mention of eliminating the drawing resistance of the wire drawing die, and it has no drawability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

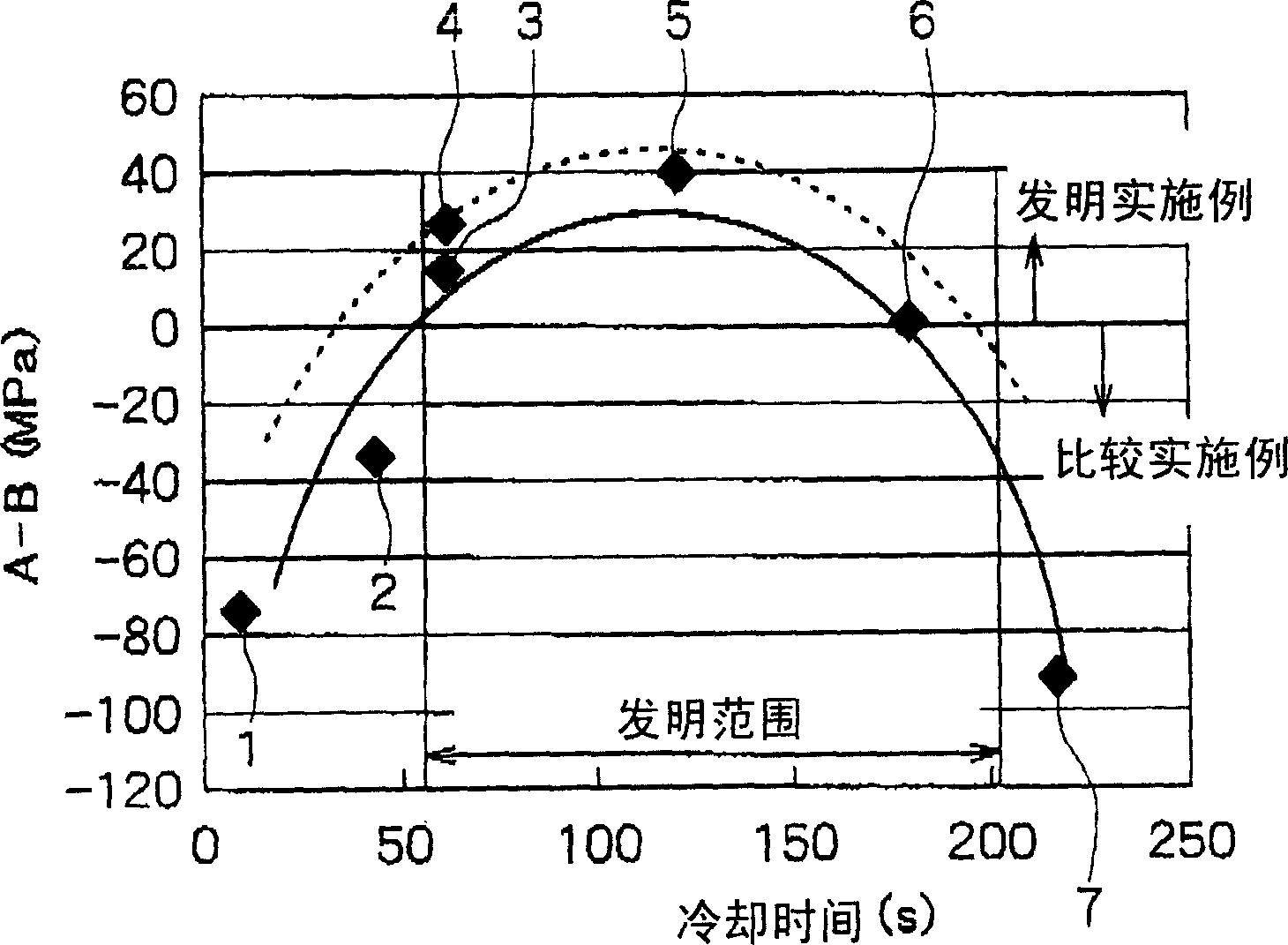

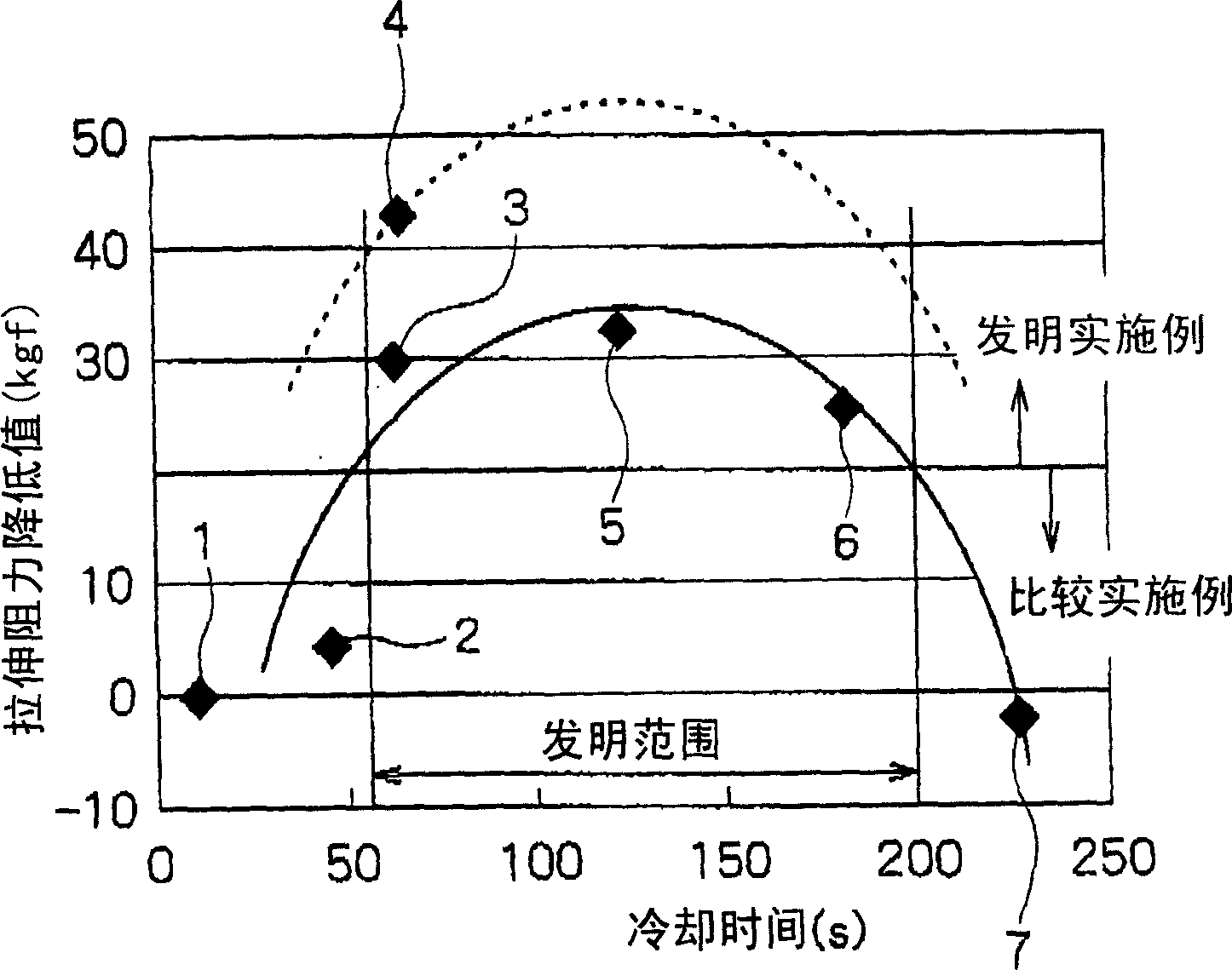

[0091] Embodiments of the present invention will be described below. In Example 1, high-carbon steel wire rods were obtained by variously changing the controlled cooling conditions (especially the cooling time for cooling the wire rods from 450°C to 300°C), and then the mechanical properties, drawability and tensile properties of the wire rods were evaluated. Stretch resistance.

[0092] From among the compositions shown in Table 1 below, high carbon steel slabs of Class 3 steel were commonly used and hot rolled, followed by controlled cooling under different conditions A to G shown in Table 2, to produce diameters of 5.5mm steel wire. In blast cooling from coiling temperature to 450°C, A, B, C, E, F and G in Table 2 may be strong blast cooling and D may be weak blast cooling, as an indication of judgment.

[0093] For these steel wire rods, the area percentage (%) of pearlite, the average interlaminar gap (nm), the average strength TS obtained by a tensile test, and RA (red...

Embodiment 2

[0111] Next, the results obtained in Example 2 are shown in Table 4. In Example 2, steel wire rods with a diameter of 5.5 mm of composition 1 to 10 in Table 1 were rolled under the conditions in Table 2, and then pairs of the same steel type were subjected to different controlled cooling conditions A (Comparative Example) and E (inventive examples). The high carbon steel thus obtained was then subjected to wire drawing in the same method as in Example 1.

[0112] Then, according to the same method as in Example 1, the pearlite area percentage (%), RA (%), average strength TS obtained by tensile test, average interlayer gap (nm), and Drawability, stretch resistance, and reduction in stretch resistance. The results obtained are shown in Table 4. The reductions in tensile resistance shown in Table 4 are comparisons (differences) between the following comparative examples and the examples of the present invention under the same type of steel, except for controlled cooling after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com