High-strength high-modulus polyethylene fiber circular-blow cooling device

A polyethylene fiber, cooling device technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problem of insufficient time for stretching the spinning solution tension, no ideal solution, and insufficient post-spinning drafting. Stability and other issues, to achieve the effect of sufficient stretching and disentanglement time, excellent draftability and stable spinning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

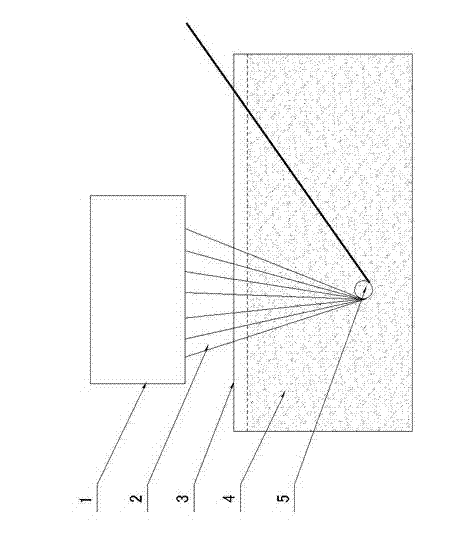

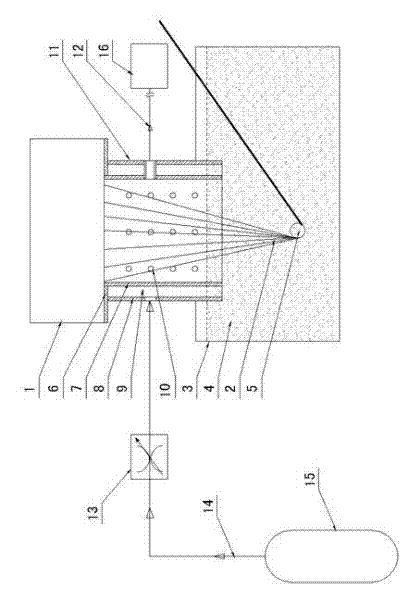

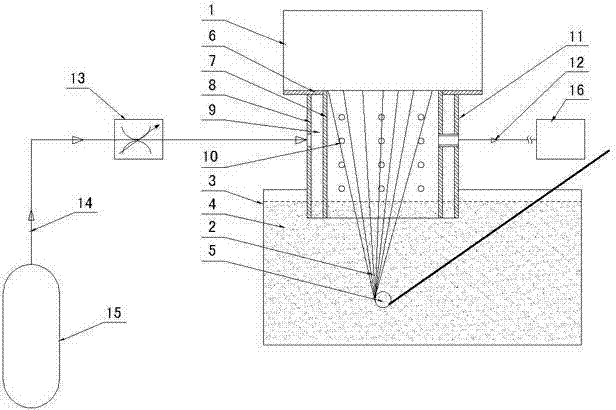

[0018] figure 2 Shown, for the present invention creates a kind of high-strength high-modulus polyethylene fiber ring air blowing cooling device specific embodiment, it comprises the air storage tank 15, throttle valve 13, cooler 11 that are used to store cooling gas, and described cooler 11 comprises The fixed seat 6 fixed on the spinneret assembly 1 and the inner cylinder 7 and the outer cylinder 8 correspondingly fixed on the fixed seat 6, the inner cylinder 7 is a hollow structure and forms the tow 2 channel, the inner cylinder 7 and the outer An annular pressure equalizing chamber 9 with the upper opening closed and the lower opening open is formed between the cylinders 8. The lower opening of the annular pressure equalizing chamber 9 is soaked in the cooling liquid 4 of the chilled water tank 3, which can prevent the cooling gas from being discharged from the lower part of the cooler 11. The wall of the inner cylinder 7 is evenly distributed with some air inlets 10 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com