Plant-derived PE masterbatch and preparation method thereof

A plant source and masterbatch technology, which is applied in the field of plant source PE masterbatch and its preparation, can solve the problems of poor melt fluidity, easy broken wire, poor hygroscopicity, etc., and achieve good melt fluidity, stable production process, and particle size Good diameter uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

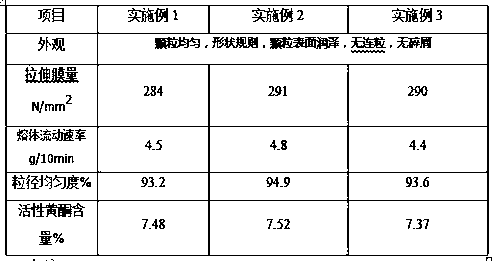

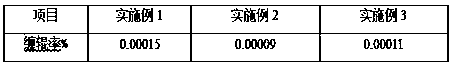

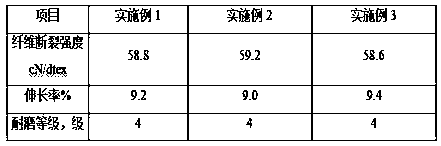

Examples

Embodiment 1

[0055] Embodiment 1 A kind of preparation method of plant source PE masterbatch

[0056] Step 1, preparation of modified motherwort extract

[0057] (1) Selection of raw materials

[0058] Motherwort extract is selected as the plant source raw material of this embodiment, and 100% of the motherwort extract passes through a 10,000-mesh sieve, the appearance of powder is loose, no agglomeration, the color is brownish yellow, and uniform; the content of active ingredients is ≥98% , the content of motherwort is 4.65%, the content of stachydrine hydrochloride is 9.42%, the sulfur content is less than or equal to 5ppm, the water is less than or equal to 3%, the total number of colonies is less than 99cfu / g, Salmonella and Escherichia coli cannot be detected, and the shelf life is 24 months.

[0059] (2) Preparation of modified motherwort extract

[0060] Mix 45 parts of motherwort extract with 28 parts of chitin and 7 parts of starch, adjust the pH to 8 with sodium carbonate, add ...

Embodiment 2

[0087] Embodiment 2 A kind of preparation method of plant source PE masterbatch

[0088] (1) Selection of raw materials

[0089] Motherwort extract is selected as the plant source raw material of this embodiment, and 100% of the motherwort extract passes through a 10,000-mesh sieve, the appearance of powder is loose, no agglomeration, the color is brownish yellow, and uniform; the content of active ingredients is ≥98% , the content of motherwort is 4.65%, the content of stachydrine hydrochloride is 9.42%, the sulfur content is less than or equal to 5ppm, the water is less than or equal to 3%, the total number of colonies is less than 99cfu / g, Salmonella and Escherichia coli cannot be detected, and the shelf life is 24 months.

[0090] (2) Preparation of modified motherwort extract

[0091] Mix 45 parts of motherwort extract with 26 parts of chitin and 6 parts of starch, adjust the pH to 7.5 with sodium carbonate, add 82 parts of deionized water and heat to 61°C for 20-30 minu...

Embodiment 3

[0118] Embodiment 3 A kind of preparation method of plant source PE masterbatch

[0119] (1) Selection of raw materials

[0120] Motherwort extract is selected as the plant source raw material of this embodiment, and 100% of the motherwort extract passes through a 10,000-mesh sieve, the appearance of powder is loose, no agglomeration, the color is brownish yellow, and uniform; the content of active ingredients is ≥98% , the content of motherwort is 4.65%, the content of stachydrine hydrochloride is 9.42%, the sulfur content is less than or equal to 5ppm, the water is less than or equal to 3%, the total number of colonies is less than 99cfu / g, Salmonella and Escherichia coli cannot be detected, and the shelf life is 24 months.

[0121] (2) Preparation of modified motherwort extract

[0122] Add 22 parts of chitin and 5 parts of starch to the above 45 parts of motherwort extract, mix, adjust the pH to 7 with sodium carbonate, add 72 parts of deionized water and heat to 50-65 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com