Rolled material for high strength spring, and wire for high strength spring using the same

a high-strength spring and rolling material technology, applied in the direction of furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of increasing manufacturing costs and resource saving, affecting the service life of the wire, etc., to achieve excellent corrosion fatigue properties, excellent drawability, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0066]The present invention will be described in more detail below by way of Examples. It should be noted that, however, these examples are never construed to limit the scope of the invention; various modifications and changes may be made without departing from the scope and spirit of the invention and should be considered to be within the scope of the invention.

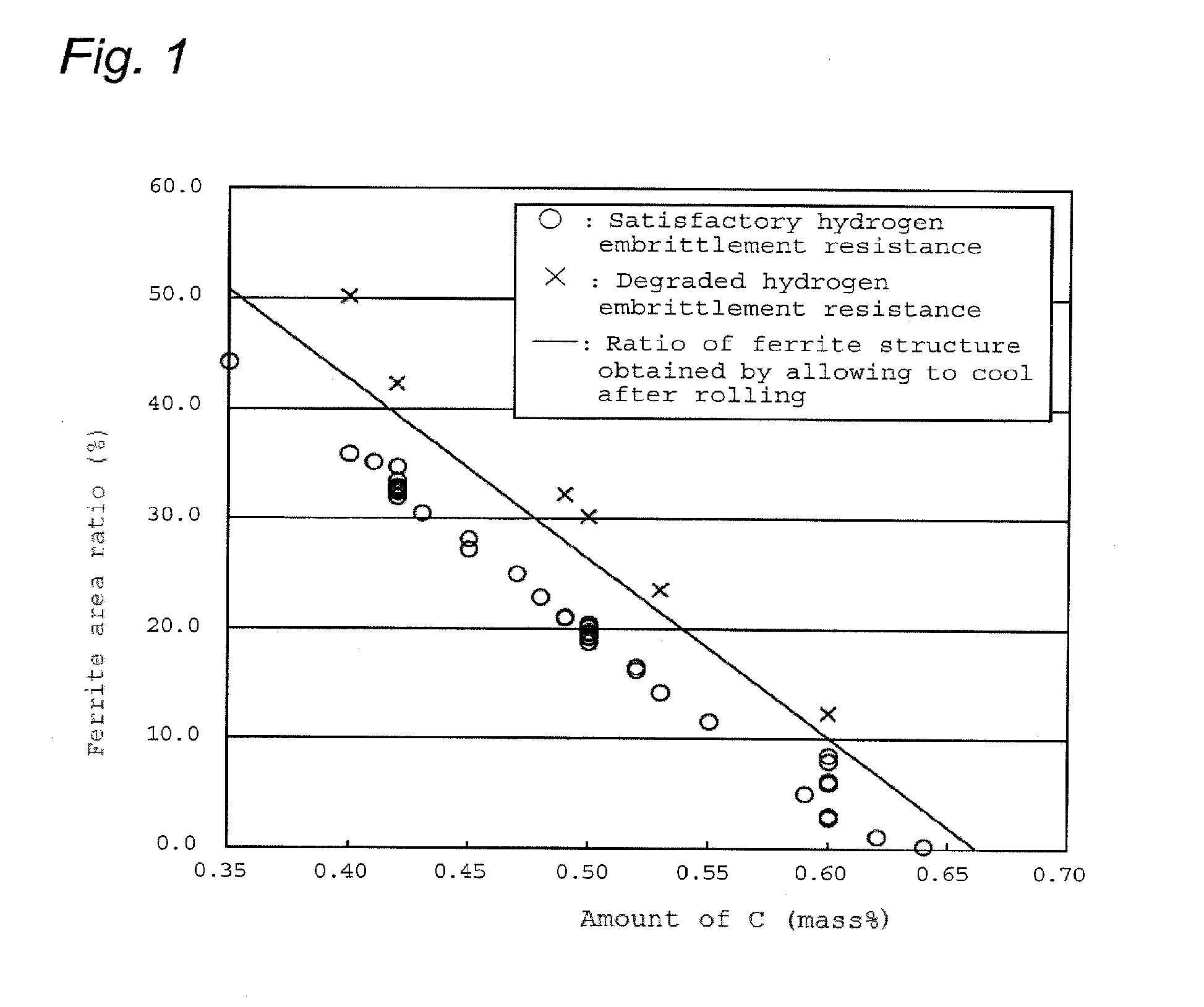

[0067]Each of steel materials having chemical compositions shown in Tables 1 to 3 was melted by melting in converter and then subjecting to continuous casting and a homogenizing treatment at 1,100° C. or higher. After the homogenizing treatment, blooming was performed, followed by heating at 1,100 to 1,280° C. and further hot rolling to obtain a wire rod having a diameter of 14.3 mm, namely, a rolled material. Whether or not a degassing treatment of a molten steel is implemented, coiling temperature TL after hot rolling, and cooling conditions after cooling are as shown in Tables 4 to 6. In test examples in which “Implementa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com