Processed mozzarella cheese and preparation method thereof

A cheese and dry mixing technology, applied in cheese substitutes, bacteria used in food preparation, dairy products, etc., can solve the problems of complex production process, high production cost, poor wire drawing, etc., and achieve a high degree of product standardization, Good baking processing characteristics, beneficial to shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

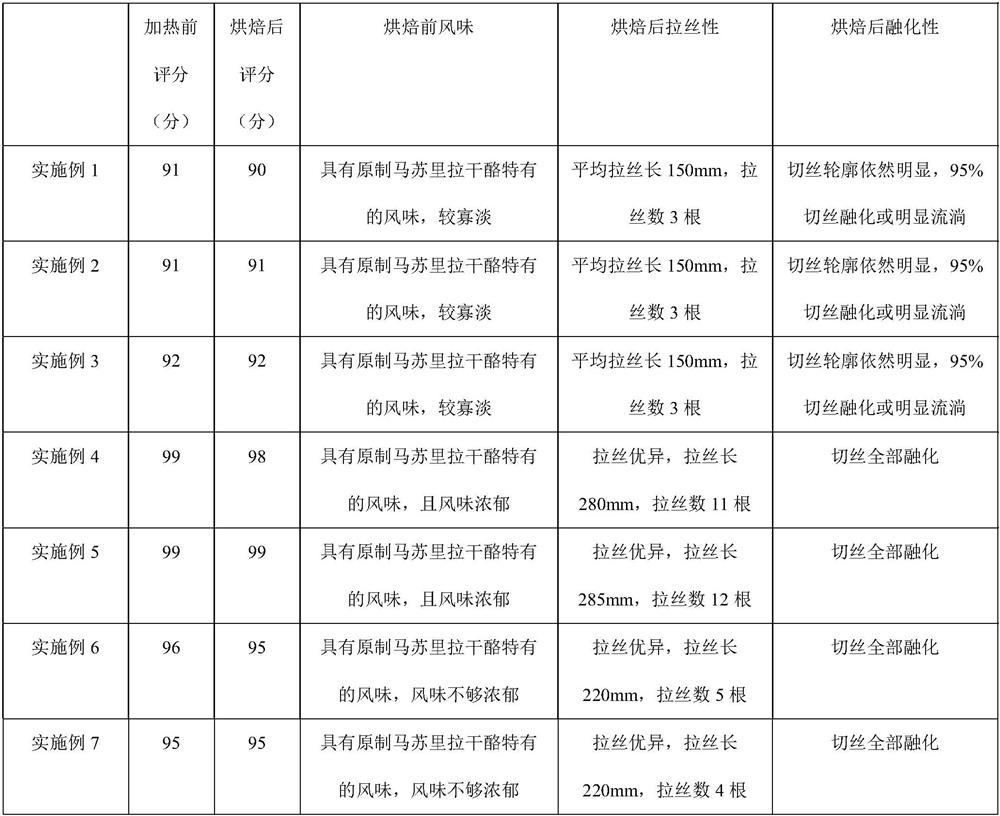

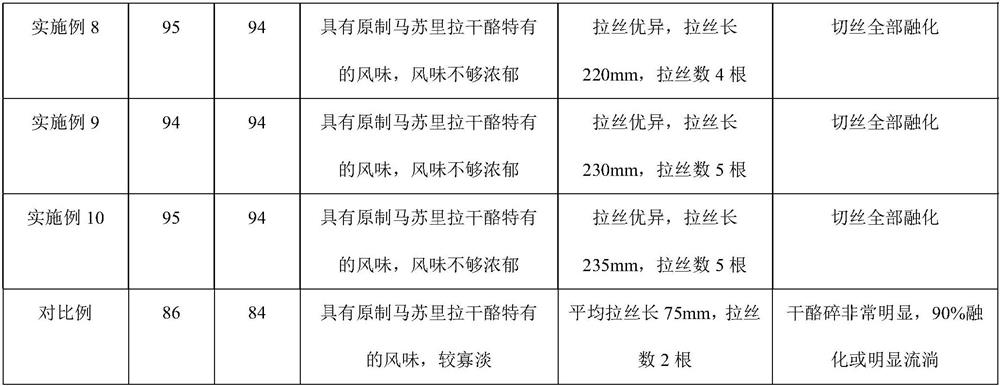

Examples

Embodiment 1

[0058] A reprocessed mozzarella cheese, in parts by weight, is made from the following raw materials: 20 parts of original mozzarella cheese, 40 parts of water, 18 parts of palm oil, 12 parts of casein, 5 parts of modified starch, 0.7 parts of sodium citrate, 0.5 parts of sodium hexametaphosphate, 0.5 parts of dipotassium hydrogen phosphate, 0.8 parts of sodium chloride, 0.4 parts of citric acid, 0.1 parts of potassium sorbate, and 3 parts of natural cheese essence.

[0059] Food additives in raw materials should meet the requirements of GB2760.

[0060] In terms of weight percentage, the nutritional composition of the original mozzarella cheese is: 22% fat, 26% protein and 52% dry matter.

[0061] The modified starch is a modified starch specially suitable for processed cheese with a high melting point, and is purchased from Houman Biotechnology (Shanghai) Co., Ltd.

[0062] The natural cheese essence is cheese with high maturity and cheese spice.

[0063] The preparation m...

Embodiment 2

[0074] A reprocessed mozzarella cheese, in parts by weight, is made from the following raw materials: 23 parts of original mozzarella cheese, 35 parts of water, 22 parts of palm oil, 8 parts of casein, 7 parts of modified starch, 0.5 parts of sodium citrate, 0.6 parts of sodium hexametaphosphate, 0.3 parts of dipotassium hydrogen phosphate, 1.2 parts of sodium chloride, 0.2 parts of citric acid, 0.2 parts of potassium sorbate, and 1 part of natural cheese essence.

[0075] Food additives in raw materials should meet the requirements of GB2760.

[0076] In terms of weight percentage, the nutritional composition of the original mozzarella cheese is: 22% fat, 26% protein and 52% dry matter.

[0077] The modified starch is a modified starch specially suitable for processed cheese with a high melting point, and is purchased from Houman Biotechnology (Shanghai) Co., Ltd.

[0078] The natural cheese essence is cheese with high maturity and cheese spice.

[0079] The preparation met...

Embodiment 3

[0090] A reprocessed mozzarella cheese, in parts by weight, is made from the following raw materials: 21 parts of original mozzarella cheese, 38 parts of water, 20 parts of palm oil, 10 parts of casein, 6 parts of modified starch, 0.6 parts of sodium citrate, 0.55 parts of sodium hexametaphosphate, 0.4 parts of dipotassium hydrogen phosphate, 1 part of sodium chloride, 0.3 parts of citric acid, 0.15 parts of potassium sorbate, and 2 parts of natural cheese essence.

[0091] Food additives in raw materials should meet the requirements of GB2760.

[0092] In terms of weight percentage, the nutritional composition of the original mozzarella cheese is: 22% fat, 26% protein and 52% dry matter.

[0093] The modified starch is a modified starch specially suitable for processed cheese with a high melting point, and is purchased from Houman Biotechnology (Shanghai) Co., Ltd.

[0094] The natural cheese essence is cheese with high maturity and cheese spice.

[0095] The preparation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com