Waste high impact polystyrene modified material and preparation method thereof

A technology for polystyrene and modified materials, which is applied in the field of waste high-impact polystyrene modified materials and its preparation, and can solve problems such as environmental hazards, rising waste, and poor mechanical properties of high-impact polystyrene , to achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing a waste high-impact polystyrene modified material, comprising the following steps:

[0039] 100 parts by weight of waste high-impact polystyrene and 0.3-1.5 parts by weight of a bisoxazoline compound are melt-blended to obtain a modified material of waste high-impact polystyrene;

[0040] The notched impact strength of the waste high-impact polystyrene is lower than 4kJ / m 2 .

[0041] In the preparation method provided by the invention, waste high-impact polystyrene and bisoxazoline compounds are firstly melt-blended. Wherein, the notched impact strength of the waste high-impact polystyrene is lower than 4kJ / m 2 .

[0042] In an embodiment provided by the present invention, the notched impact strength of the waste high-impact polystyrene is lower than 3kJ / m 2 ; In another embodiment provided by the present invention, the notched impact strength of the waste high-impact polystyrene is less than or equal to 2.8kJ / m 2 .

...

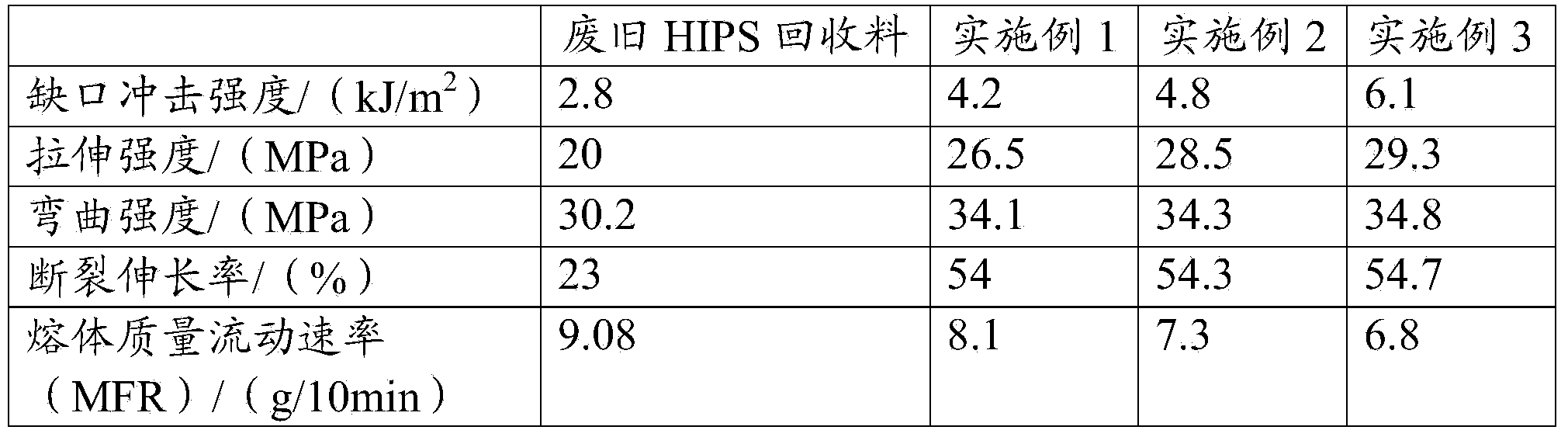

Embodiment 1

[0057] Grind waste high-impact polystyrene recycled materials into flakes with a length of less than 1cm, a width of less than 5mm, and a thickness of less than 2mm, and then mix 500g of the crushed flakes with 1,3-bis(2-oxazoline ) 2.5 g of benzene was placed in a blast drying oven, and dried at 80° C. for 12 hours. After drying, the dried waste high-impact polystyrene recycled material and 1,3-bis(2-oxazolinyl)benzene are uniformly mixed and fed into a twin-screw extruder. Waste high-impact polystyrene recycled materials and 1,3-bis(2-oxazolinyl)benzene are melt-blended in a twin-screw extruder and then extruded at a temperature of 190°C. The discharged material is cooled and granulated in sequence to obtain waste high-impact polystyrene modified materials.

[0058] In this example, the waste high-impact polystyrene recycled materials used are provided by Zhengzhou Shuangcheng Plastic Tray Preparation Co., Ltd., and the notched impact strength of the waste high-impact polys...

Embodiment 2

[0060] Grind waste high-impact polystyrene recycled materials into flakes with a length of less than 1cm, a width of less than 5mm, and a thickness of less than 2mm, and then mix 500g of the crushed flakes with 1,3-bis(2-oxazoline ) 4.5 g of benzene was placed in a blast drying oven, and dried at 80° C. for 12 hours. After drying, the dried waste high-impact polystyrene recycled material and 1,3-bis(2-oxazolinyl)benzene are uniformly mixed and fed into a twin-screw extruder. Waste high-impact polystyrene recycled materials and bisoxazoline compound 1,3-bis(2-oxazoline)benzene were extruded after melt blending in a twin-screw extruder, and the extrusion temperature was 190°C. The extruded material obtained by extrusion is cooled and granulated in sequence to obtain waste high-impact polystyrene modified material.

[0061] In this embodiment, the waste high-impact polystyrene recycled material used is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com