Flame-retardant reinforced heat stable ABS composite material and preparation method thereof

A composite material and thermal stabilization technology, applied in the field of flame retardant and thermally stable ABS composite material and its preparation, can solve the problems of poor flame retardancy and poor thermal stability of ABS resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

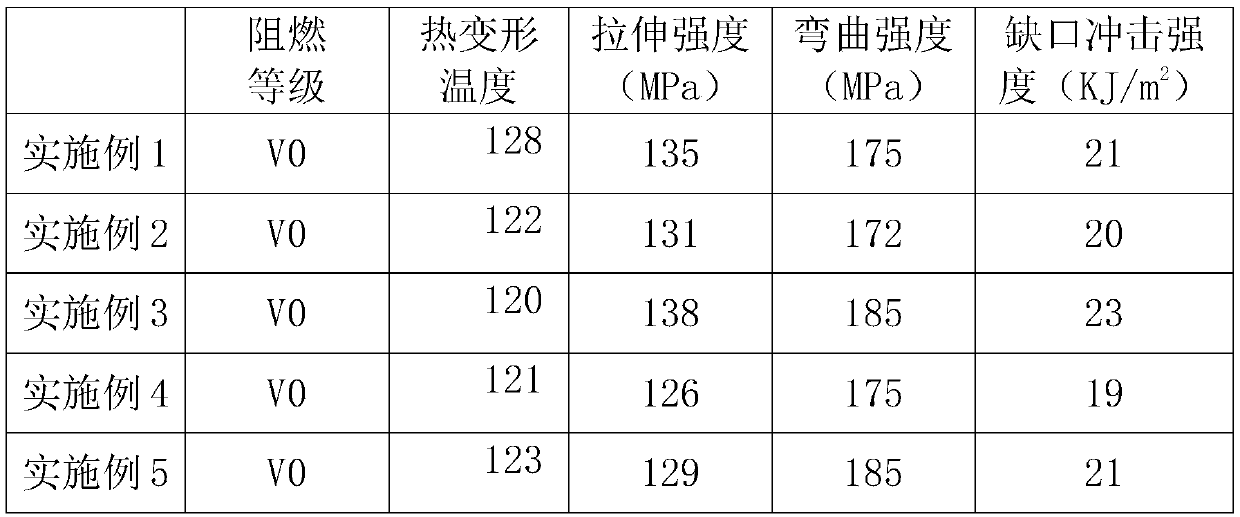

Examples

Embodiment 1

[0022] This embodiment provides a flame retardant enhanced heat stable ABS composite material, 80 parts of ABS resin, 20 parts of thermosetting resin, 8 parts of triazine boron flame retardant, 2 parts of sulfonate flame retardant, kevlar chopped fiber 8 parts, 3 parts of cellulose dispersant, 0.8 part of hyperbranched polyester, 3 parts of heat stabilizer, the structural formula of described triazine boron series flame retardant is: R is a hydrogen atom.

[0023] The melt index of the ABS resin at 220°C and a load of 10Kg is 25g / 10min, and the water content is not more than 0.05wt%. More than 15 μm, the cellulose dispersant is ethyl cellulose, the hyperbranched polyester is SeHBP H101, the heat stabilizer is 3,5-di-tert-butyl-4-hydroxybenzyl diethyl phosphate, The sulfonate flame retardant is sodium benzenesulfonylsulfonate.

[0024] The preparation method of the flame-retardant reinforced thermally stable ABS composite material is as follows:

[0025] Stir and mix ABS re...

Embodiment 2

[0028] This embodiment provides a flame retardant enhanced heat stable ABS composite material, 75 parts of ABS resin, 15 parts of thermosetting resin, 5 parts of triazine boron flame retardant, 1 part of sulfonate flame retardant, kevlar chopped fiber 5 parts, 2 parts of cellulose dispersant, 0.5 part of hyperbranched polyester, 1 part of heat stabilizer, the structural formula of the triazine boron series flame retardant is: R is methyl.

[0029] The melt index of the ABS resin at 220°C and a load of 10Kg is 20g / 10min, and the water content is not more than 0.05wt%. More than 15 μm, the cellulose dispersant is butyl cellulose, the hyperbranched polyester is SeHBP H201, the heat stabilizer is dioctadecyl pentaerythritol diphosphite, and the sulfonate flame retardant Potassium perfluorobutane sulfonate.

[0030] The preparation method of the flame-retardant reinforced thermally stable ABS composite material is as follows:

[0031] Stir and mix ABS resin, thermosetting resin...

Embodiment 3

[0034] This embodiment provides a flame retardant enhanced heat stable ABS composite material, 85 parts of ABS resin, 25 parts of thermosetting resin, 10 parts of triazine boron flame retardant, 3 parts of sulfonate flame retardant, kevlar chopped fiber 10 parts, 3 parts of cellulose dispersant, 1 part of hyperbranched polyester, 1-5 parts of heat stabilizer, the structural formula of the triazine boron-based flame retardant is: R is ethyl.

[0035] The melt index of the ABS resin at 220°C and a load of 10Kg is 30g / 10min, and the water content is not more than 0.05wt%. The thermosetting resin is melamine formaldehyde resin. No more than 15 μm, the cellulose dispersant is hydroxycellulose, the hyperbranched polyester is SeHBP H301, the heat stabilizer is octadecyl thiodipropionate, and the sulfonate flame retardant is para Sodium dibenzenesulfonate.

[0036] The preparation method of the flame-retardant reinforced thermally stable ABS composite material is as follows:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com