Hybrid supported metallocene catalyst, and polyolefin resin having excellent processability and using same

A metallocene catalyst and metallocene compound technology, applied in the field of supported hybrid metallocene catalyst and its preparation, can solve the problems of no display gap, resin molecular weight gap, no display molecular weight gap, etc., and achieve excellent processability and excellent impact strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

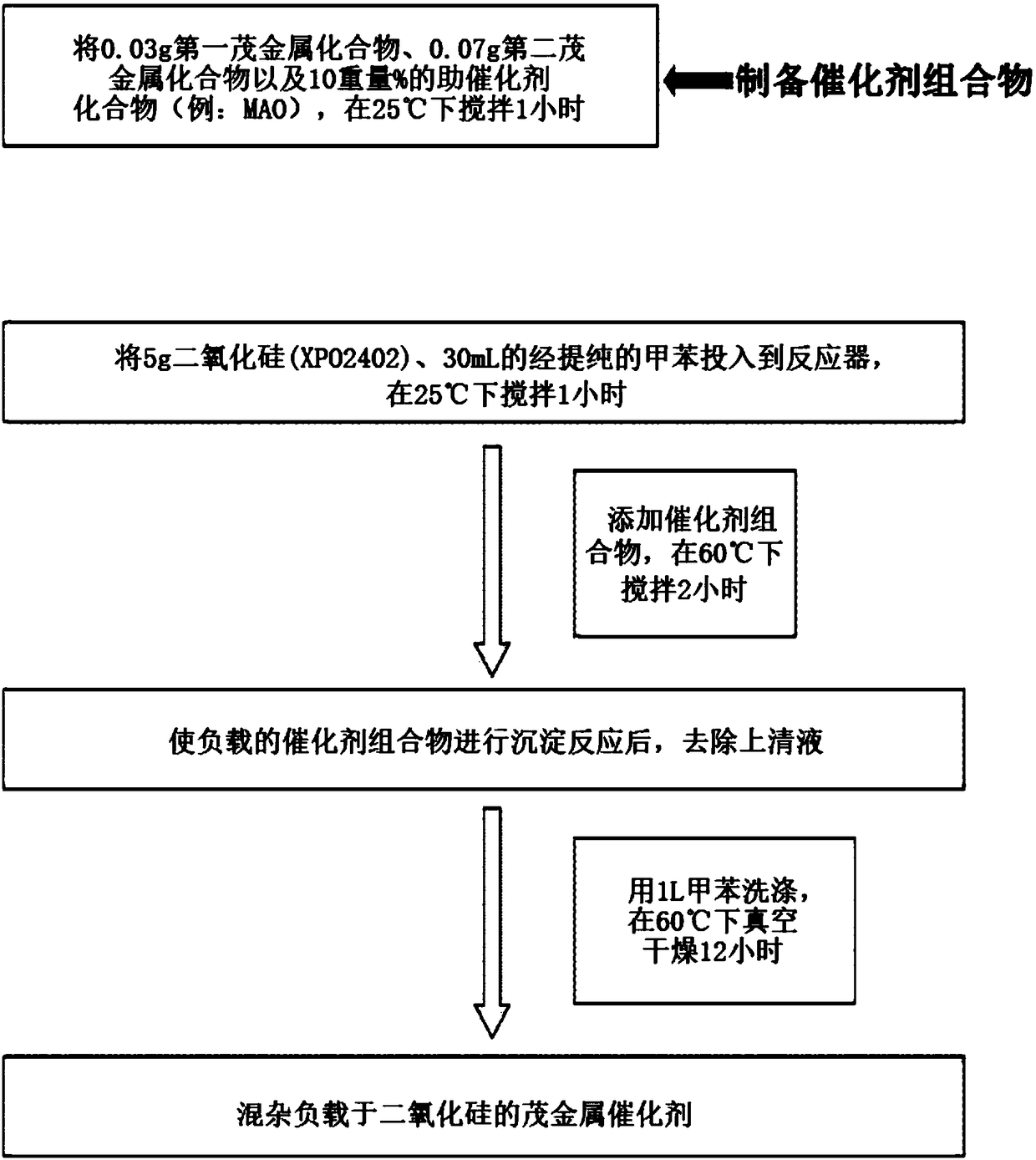

preparation example Construction

[0174] The preparation method of the polyolefin resin involved in the present invention comprises the step of contacting the supported hybrid metallocene catalyst with at least one olefin monomer and preparing a polyolefin homopolymer or copolymer.

[0175] The preparation method (polymerization reaction) of the polyolefin resin of the present invention may be a slurry phase or a gas phase polymerization reaction. In addition, each polymerization reaction condition can be changed variously according to the polymerization method (slurry polymerization, gas phase polymerization reaction), the desired polymerization result, or the form of the polymer. The degree of deformation can be easily realized by those skilled in the art.

[0176] When the polymerization is carried out in a slurry phase, a solvent or the olefin itself may be used as a medium. The solvent may be propane, butane, pentane, hexane, octane, decane, dodecan, cyclopentane, methylcyclopentane, cyclohexane, methylc...

preparation example 1

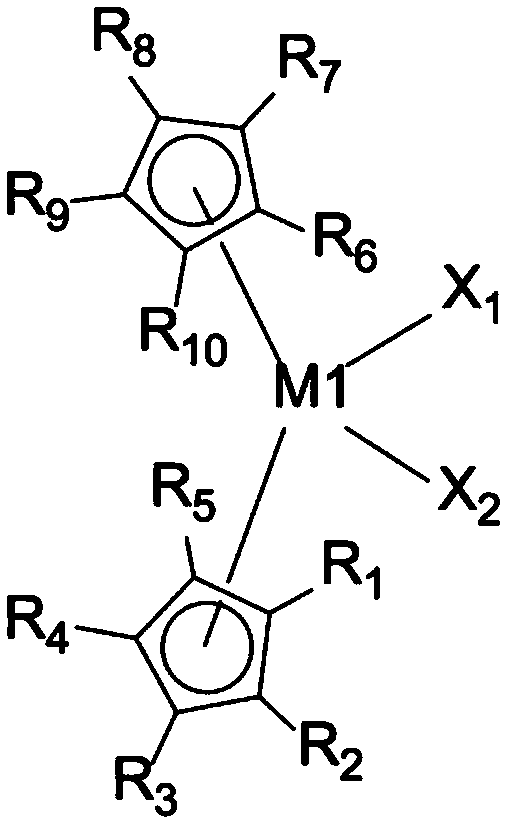

[0192] Preparation example 1 of the first metallocene compound: (indenyl (cyclopentadienyl)) zirconium dichloride [(Indenyl (cyclopentadienyl)] ZrCl 2 ) preparation

[0193] Indene (5g, 0.043mol) was dissolved in hexane (150mL) and then fully stirred. After cooling to -30°C, 2.5M n-butyllithium (n-BuLi) hexane solution was slowly dripped into the hexane solution ( 17mL, 0.043mol), stirred at room temperature for 12 hours. The white suspension was filtered through a glass filter, and after the white solid was sufficiently dried, indene lithium salt was obtained (yield: 99%).

[0194] Indene lithium salt (1.05g, 8.53mmol) slurry (slurry) solution and (cyclopentadienyl) zirconium trichloride ((cyclopentadienyl) ZrCl 3 ) (2.24g, 8.53mmol) was slowly dissolved in ether (30mL) and cooled to -30°C. Into this ether solution, indene lithium salt dissolved in ether (15 mL) was slowly added dropwise, followed by stirring for 24 hours to obtain (indenyl(cyclopentadienyl))zirconium dich...

preparation example 2

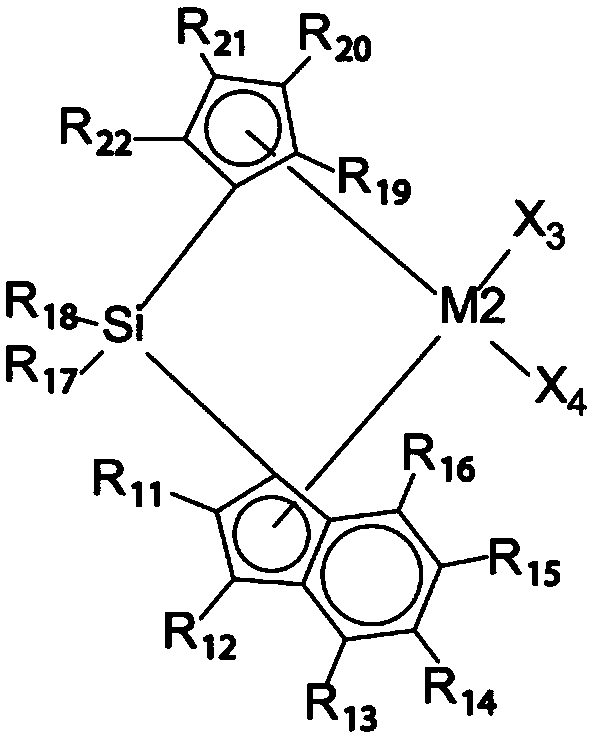

[0195] Preparation Example 2 of the First Metallocene Compound: (2-Methylbenzo[e]indenyl(cyclopentadienyl))zirconium dichloride[(2-methyl benzoindenyl(cyclopentadienyl)]ZrCl 2 ) preparation

[0196] Using 2-methylbenzo[e]indene (2-methylbenzoindene), obtain (2-methylbenzo[e]indenyl (cyclopentadienyl)) dichloride by the same method as Preparation Example 1 Zirconium ([2-methyl benzoindenyl(cyclopentadienyl)]ZrCl 2 ) (yield: 95%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com