Long chain branching polypropylene random copolymer and preparation method thereof

A technology of random copolymerization and long-chain branching, which is applied in the field of preparation of random copolymerized polypropylene, can solve problems such as shortage, and achieve the goal of increasing β-crystal content, excellent processability and mechanical properties, and low melt flow rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

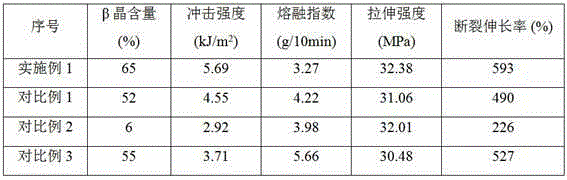

Embodiment 1

[0039] The preparation method of the embodiment of the present invention 1 is as follows:

[0040] 1) Weigh 4 parts by weight of rare earth organic complex β-nucleating agent and evenly disperse it in a small amount of acetone to form the first dispersion liquid, and then uniformly mix it with 96 parts by weight of random copolymerized polypropylene and volatilize the solvent before extruding on twin-screw Melt extrusion granulation in the machine, the heating temperature of each section of the extruder is: 170°C, 180°C, 190°C, 195°C, 200°C, 195°C, the screw speed is 120rpm, and the β masterbatch is obtained;

[0041] 2) Evenly mix 0.03 parts by weight of dibenzoyl peroxide and 1.5 parts by weight of trimethylolpropane triacrylate in a small amount of acetone to form a second dispersion, and then mix with 100 parts by weight of random copolymerized polypropylene, 7.5 parts by weight of the above-mentioned β masterbatch (equivalent to 0.3 parts by weight of β-nucleating agent),...

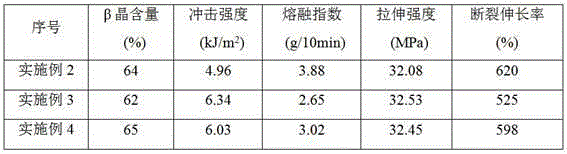

Embodiment 2

[0060] The preparation method of embodiment 2 is as follows:

[0061] 1) Weigh 4 parts by weight of the rare earth organic complex β-nucleating agent and evenly disperse it in a small amount of acetone to form the first dispersion liquid, and then mix it with 96 parts by weight of random copolymerized polypropylene and volatilize the solvent before extruding on a twin-screw Melting extrusion granulation in the extruder, the heating temperature of each section of the extruder is: 160°C, 175°C, 185°C, 195°C, 200°C, 195°C, the screw speed is 130rpm, and the β masterbatch is obtained;

[0062] 2) Evenly mix 0.03 parts by weight of azobisisobutyronitrile and 1 part by weight of trimethylolpropane triacrylate in a small amount of acetone to form a second dispersion, and then mix them with 100 parts by weight of random copolymerized polypropylene, 7.5 parts by weight of the above-mentioned random β masterbatch and 0.05 parts by weight of antioxidant are mechanically mixed uniformly a...

Embodiment 3

[0065] The preparation method of embodiment 3 is as follows:

[0066] 1) Weigh 4 parts by weight of the rare earth organic complex β-nucleating agent and evenly disperse it in a small amount of acetone to form the first dispersion liquid, and then mix it with 96 parts by weight of random copolymerized polypropylene and volatilize the solvent before extruding on a twin-screw Melting extrusion granulation in the extruder, the heating temperature of each section of the extruder is: 170°C, 180°C, 190°C, 195°C, 200°C, 195°C, the screw speed is 130rpm, and the β masterbatch is obtained;

[0067] 2) Evenly mix 0.03 parts by weight of azobisisobutyronitrile and 2 parts by weight of trimethylolpropane triacrylate in a small amount of acetone to form a second dispersion, and then mix them with 100 parts by weight of random copolymerized polypropylene, 10 parts by weight of the above-mentioned β masterbatch and 0.05 parts by weight of antioxidant are mechanically mixed uniformly and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com