Waste polypropylene long branched chain material and preparation method thereof

A waste polypropylene, long-chain branched technology, applied in the field of polymer materials, can solve the problems of waste of resources, environment, pollution, etc., and achieve the effects of good mechanical properties and good melt flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the preparation process of waste polypropylene graft, the mass ratio of polypropylene for waste household appliances, initiator, styrene and epoxy functional monomer is 100:0.1~2: 0.1~10: 0.1~10, preferably 100 :0.1~0.5:3~6:3~6, more preferably 100:0.1~0.2:4~5:4~5. The melting temperature of the prepared waste polypropylene graft is preferably 180-210°C, more preferably 185-205°C.

[0035] The present invention has no specific limitation on the equipment used in the melt blending of polypropylene for waste household appliances, initiator, styrene and epoxy functional monomers, preferably a twin-screw extruder well known to those skilled in the art. In the present invention, during the operation of the twin-screw extruder, the temperature of each section from the feeding port to the machine head is preferably 185°C, 190°C, 195°C, 200°C, 205°C, 205°C, 200°C, 190°C, 185°C; the rotational speed of the twin-screw extruder is preferably 82r / min.

[0036] During the blend...

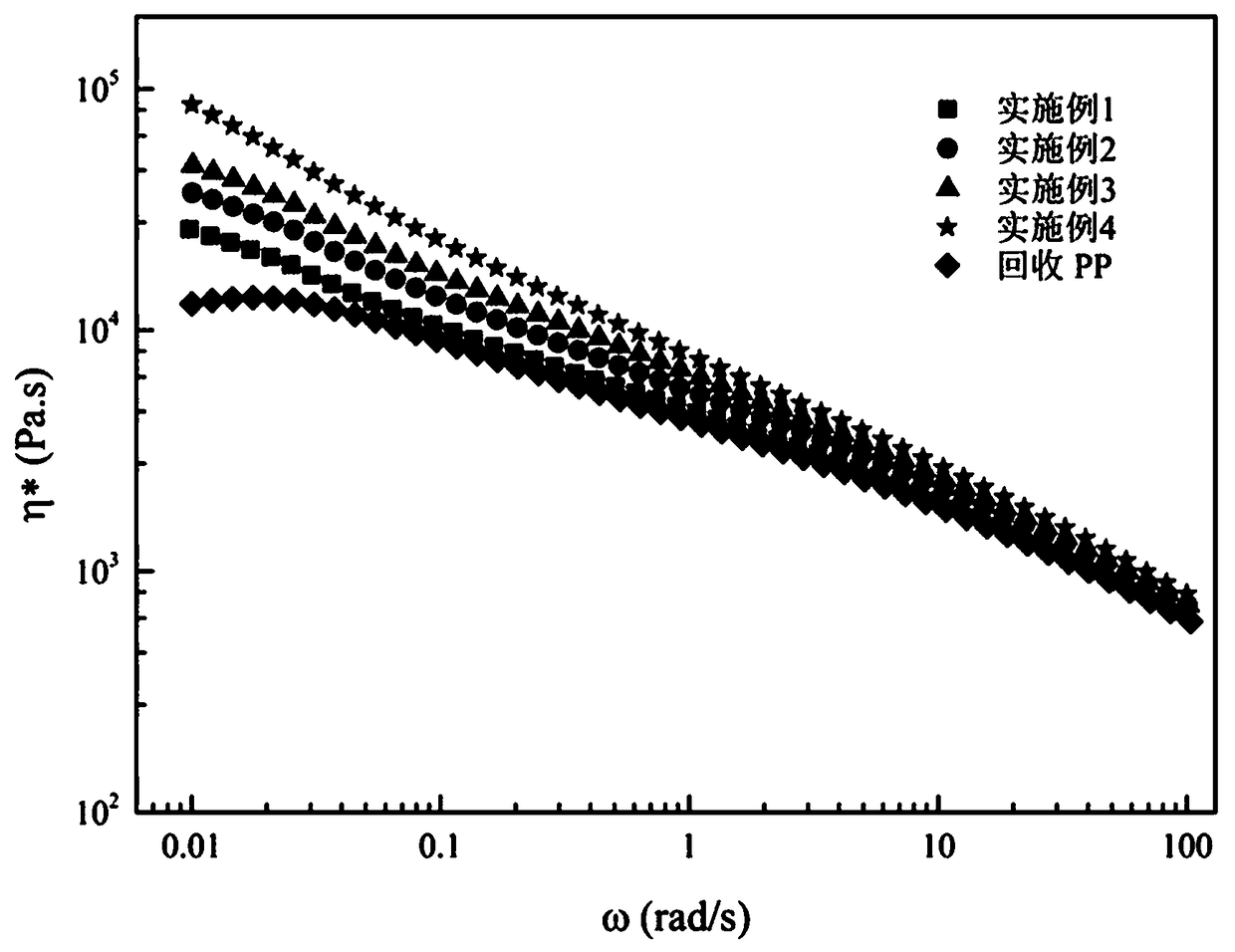

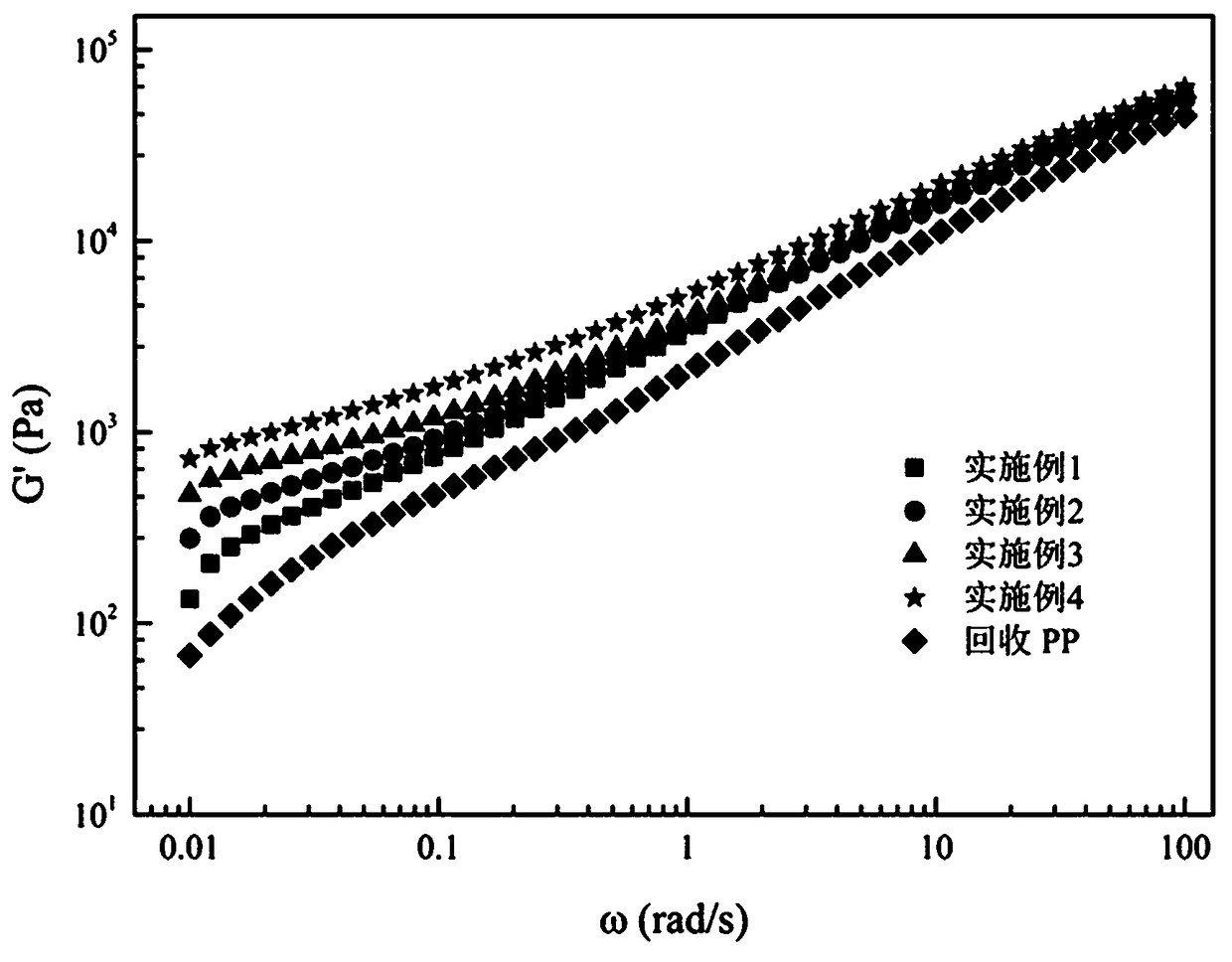

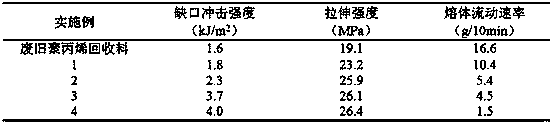

Embodiment 1

[0043]The polypropylene used for waste household appliances was crushed into a particle size of 5-15mm, and then the polypropylene used for household appliances was placed in a vacuum drying oven and dried for 10 hours at a drying temperature of 100°C. After mixing 100g of polypropylene for waste household appliances, 0.2g of dicumyl peroxide, 4.0g of styrene and 4.0g of glycidyl methacrylate, they were added to a twin-screw extruder, and the twin-screw extruder was set. The temperature of each section from the feeding port to the head of the machine: 185°C, 190°C, 195°C, 200°C, 205°C, 205°C, 200°C, 190°C, 185°C, and the screw speed is 82r / min. The material is melt-extruded and granulated to prepare waste polypropylene grafts. The particle size of waste polypropylene grafts is 3-5 mm; the pellets of waste polypropylene grafts are placed in a vacuum drying oven and dried for 10 hours. The drying temperature was 100°C. The waste polypropylene graft of 100g, the maleic anhydride...

Embodiment 2

[0046] The polypropylene used for waste household appliances was crushed into a particle size of 5-15mm, and then the polypropylene used for household appliances was placed in a vacuum drying oven and dried for 10 hours at a drying temperature of 100°C. After mixing 100g of polypropylene for waste household appliances, 0.2g of dicumyl peroxide, 4.0g of styrene and 4.0g of glycidyl methacrylate, they were added to a twin-screw extruder, and the twin-screw extruder was set. The temperature of each section from the feeding port to the head of the machine: 185°C, 190°C, 195°C, 200°C, 205°C, 205°C, 200°C, 190°C, 185°C, and the screw speed is 82r / min. The material is melt-extruded and granulated to prepare waste polypropylene grafts. The particle size of waste polypropylene grafts is 3-5 mm; the pellets of waste polypropylene grafts are placed in a vacuum drying oven and dried for 10 hours. The drying temperature was 100°C. The waste polypropylene graft of 100g, the maleic anhydrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com