Electronic part installing method and installing device

A technology of electronic parts and installation methods, applied in the direction of electrical components, electrical components, etc., can solve problems such as easy misalignment, position deviation, and increase in types of holding tools, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

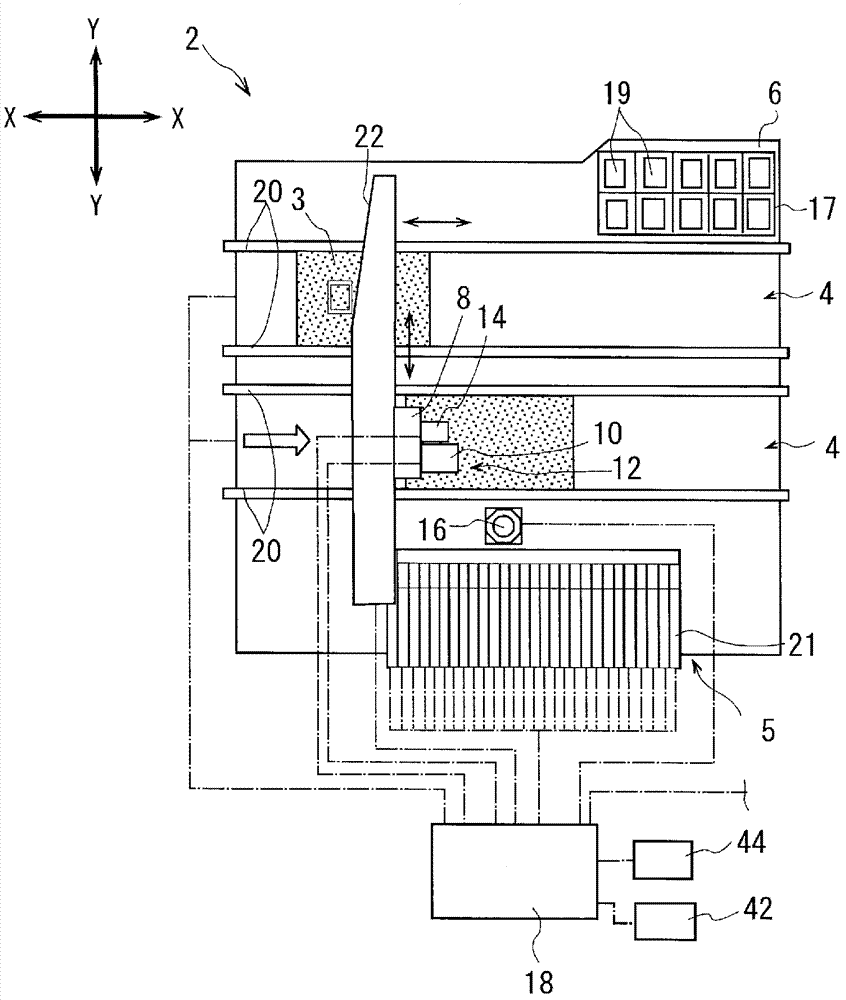

[0045] Hereinafter, 1st Embodiment of the electronic component mounting apparatus which implements the electronic component mounting method of this invention is demonstrated based on drawing.

[0046] Such as figure 1 As shown, the electronic component mounting apparatus 2 includes: a substrate transfer device 4 for carrying a substrate 3 into a loading position and positioning it at a predetermined position; a component supply device 5; Device 12 and mark identification camera 14, the mobile platform 8 is supported to be able to move in the horizontal direction relative to the base platform 6, that is, the X direction and the Y direction; the part identification camera 16 fixed on the base platform 6; The control device 18 for the installation performed by the carrier device 12.

[0047] The substrate transfer device 4 is a so-called double-conveyor type, and each conveyor includes: parallel conveyor belts (not shown), arranged side by side along the guide rail 20 extending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com