Sputtering device

A sputtering device and sputtering method technology, applied in sputtering coating, vacuum evaporation coating, coating, etc., can solve the problems of volume increase, building configuration, complex vacuum sealing structure, and rising manufacturing costs. Achieve the effects of reducing the occurrence of poor film formation, reducing the occurrence of particles, and increasing the amount of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Next, a sputtering device according to an embodiment of the present invention will be described based on the drawings. In addition, the present embodiment is specifically described for better understanding of the gist of the present invention, and does not limit the present invention unless otherwise specified.

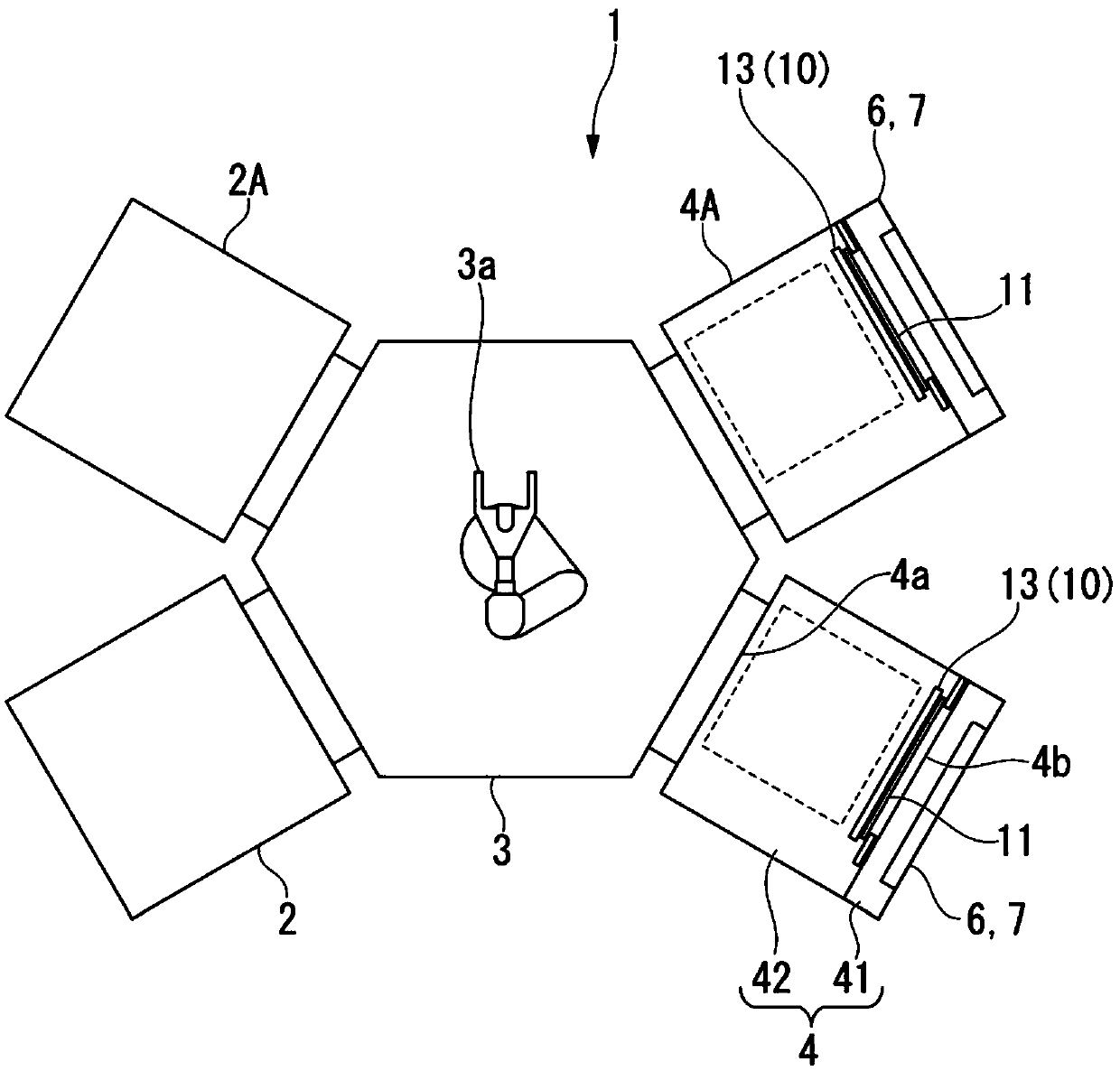

[0061] figure 1 is a schematic plan view showing the sputtering device according to the present embodiment, and figure 1 Among them, reference numeral 1 is a sputtering device.

[0062] The sputtering device 1 according to the present embodiment is used for a substrate to be processed formed of glass or resin, for example, when a TFT (Thin film transistor, thin film transistor) is formed on a substrate formed of glass or the like in a manufacturing process of a liquid crystal display. Reciprocating vacuum processing equipment that performs heat processing, film formation processing, etching processing, etc. in a vacuum environment.

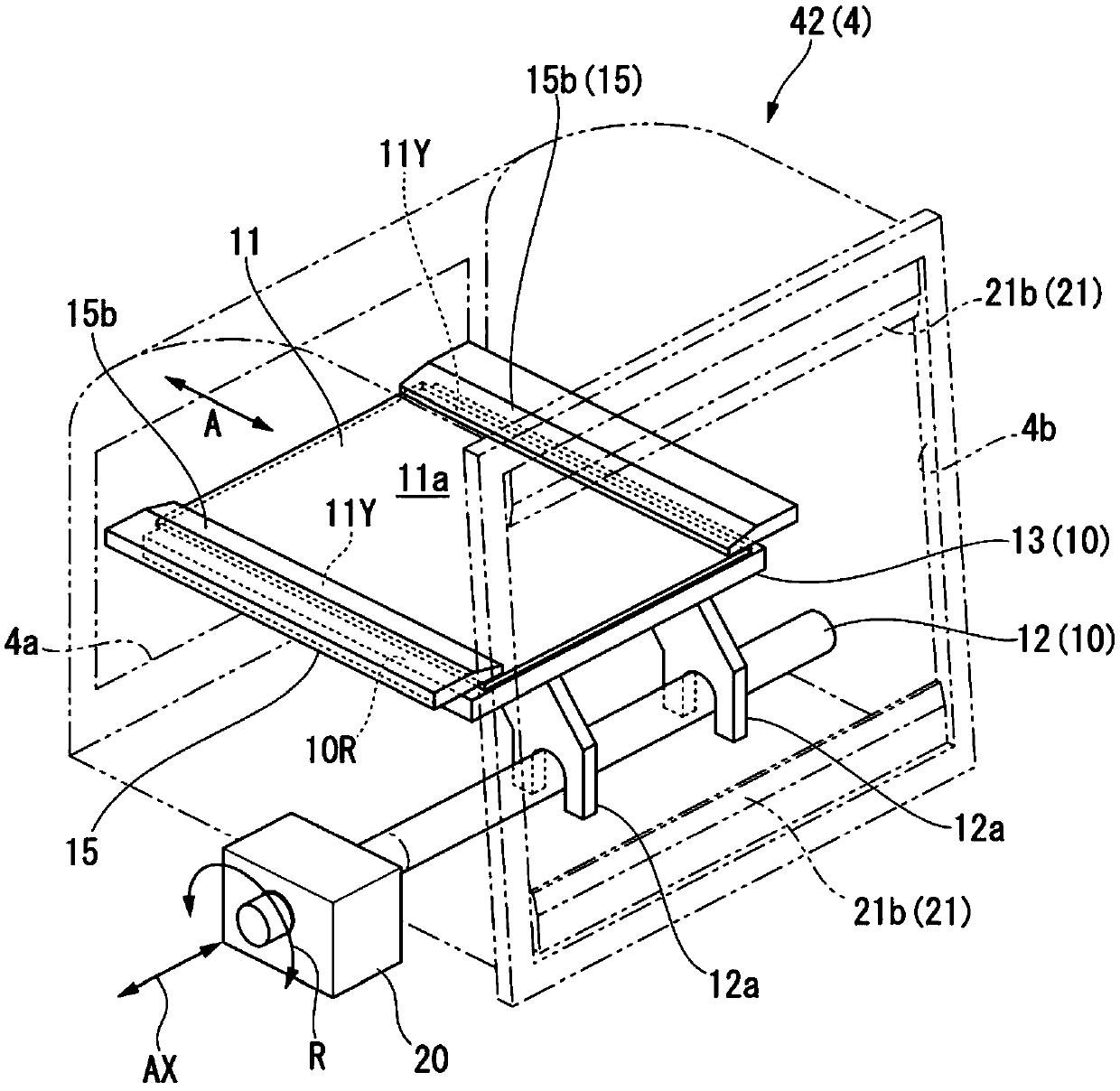

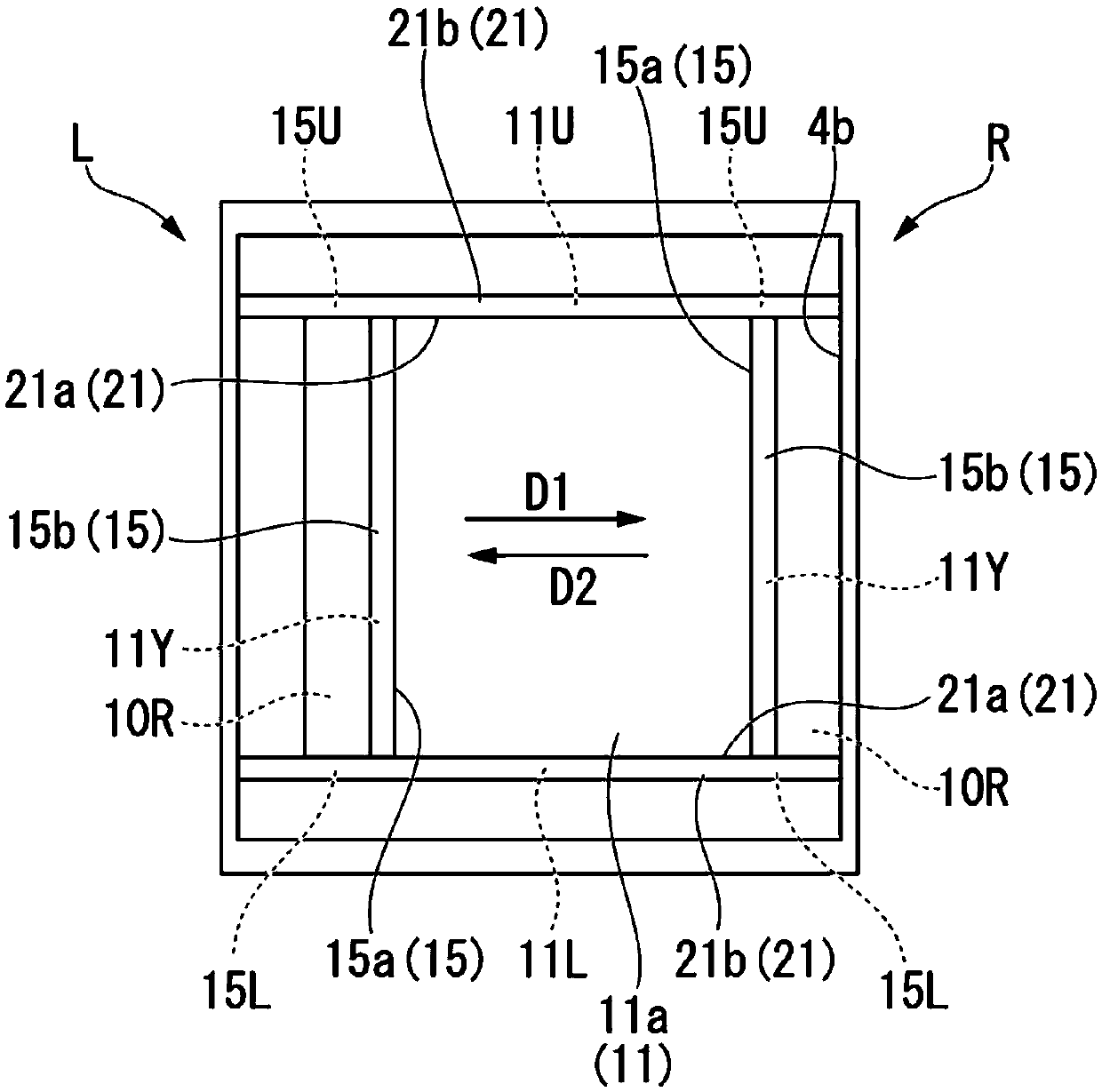

[0063] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com