Method for intermittently coating battery pole piece

A battery pole piece and coating method technology, applied to battery electrodes, devices for coating liquid on the surface, circuits, etc., can solve problems such as coating thickness deviation, U-shape, and influence on the uniformity of the pole piece, and achieve additional The effect of quantity control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Preparation of slurry

[0017] Mix 143 grams of positive electrode active ingredient LiFePO4, 6.4 grams of conductive agent SP, 9.55 grams of binder polyvinylidene fluoride PVDF, and 262 grams of N-methylpyrrolidone, and then stir in a vacuum mixer to form a uniform positive electrode slurry.

[0018] (2) intermittent coating

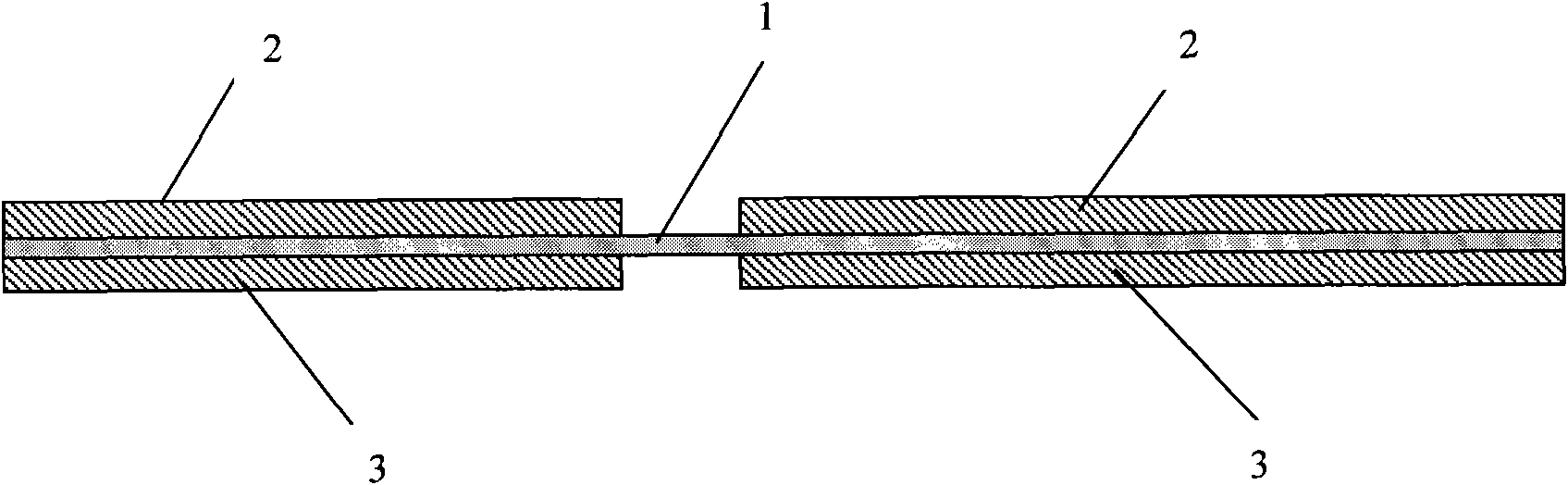

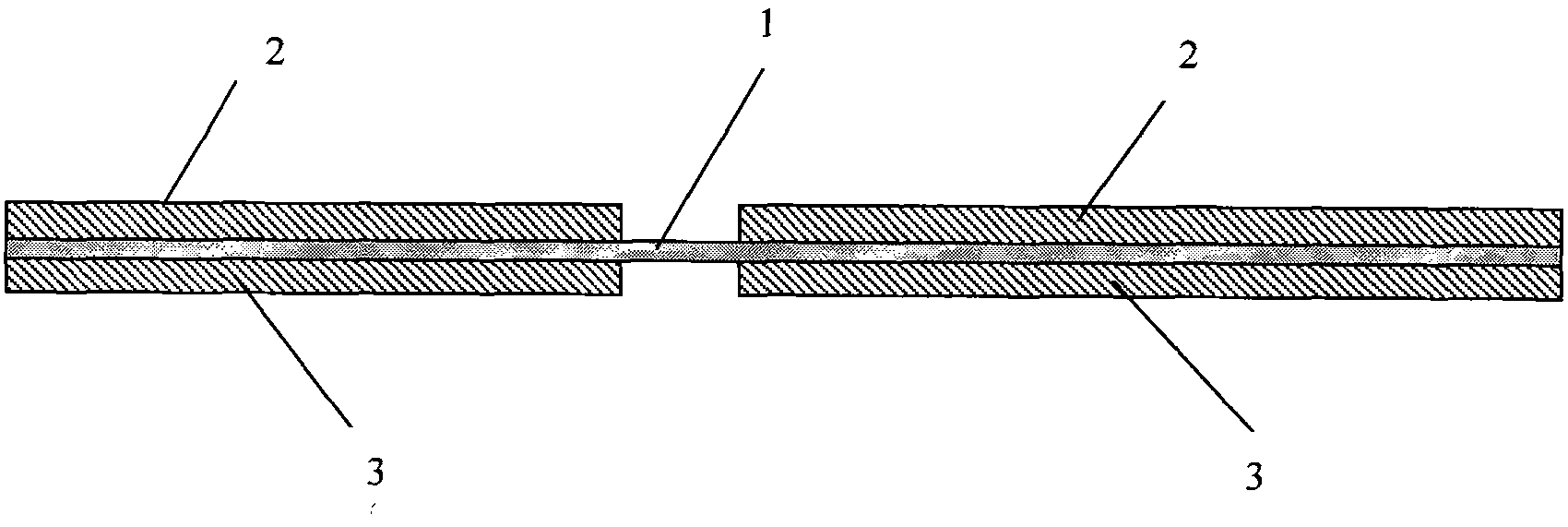

[0019] according to figure 1 The process shown is intermittent coating; the specific operation steps are:

[0020] A, the slurry prepared in step (1) is carried out one-sided coating to pole piece 1 according to above-mentioned process, first coat slurry 2,

[0021] B. The intermittent distance on one side of slurry 2 is 8mm;

[0022] C. Dry the coated single-sided pole piece and pass through the coating machine head once;

[0023] D. Carry out intermittent coating on the second side of the single-sided pole piece that has passed through the empty strip, coat the slurry 3, and dry the product after coating;

[0024] The prepared product ...

Embodiment 2

[0027] Mix 143 grams of positive electrode active ingredient LiFePO4, 6.4 grams of conductive agent SP, 9.55 grams of binder polyvinylidene fluoride PVDF, and 262 grams of N-methylpyrrolidone, and then stir in a vacuum mixer to form a uniform positive electrode slurry.

[0028] (2) intermittent coating

[0029] according to figure 1 The process shown is for coating, and the specific operation steps are:

[0030] a. The slurry prepared in step (1) is coated on one side according to the above process, and the pole piece 1 is first coated with the slurry 2;

[0031] b. The intermittent distance of one side of slurry 2 is 10mm;

[0032] c. Dry the coated single-sided pole piece and pass through the coating machine head once;

[0033] D, carry out the second side intermittent coating of the single-sided pole piece that has passed the empty band, carry out the coating of slurry 3, dry and make product after coating is finished;

[0034] The prepared product was tested, and the m...

Embodiment 3

[0037] Mix 143 grams of positive electrode active ingredient LiFePO4, 6.4 grams of conductive agent SP, 9.55 grams of binder polyvinylidene fluoride PVDF, and 262 grams of N-methylpyrrolidone, and then stir in a vacuum mixer to form a uniform positive electrode slurry.

[0038] (2) intermittent coating

[0039] according to figure 1 The process shown is for coating, and the specific operation steps are:

[0040] 1) The slurry prepared in step (1) is coated on one side according to the above-mentioned process, first, the pole piece 1 is coated with the slurry 2;

[0041] 2) The intermittent distance of slurry 2 coating on one side is 5mm;

[0042] 3) Dry the coated single-sided pole piece and pass through the coating machine head once;

[0043] 4) Carry out intermittent coating on the second side of the single-sided pole piece that has passed through the empty strip, and then coat the slurry 3, and dry the product after the coating is completed;

[0044] The prepared produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com