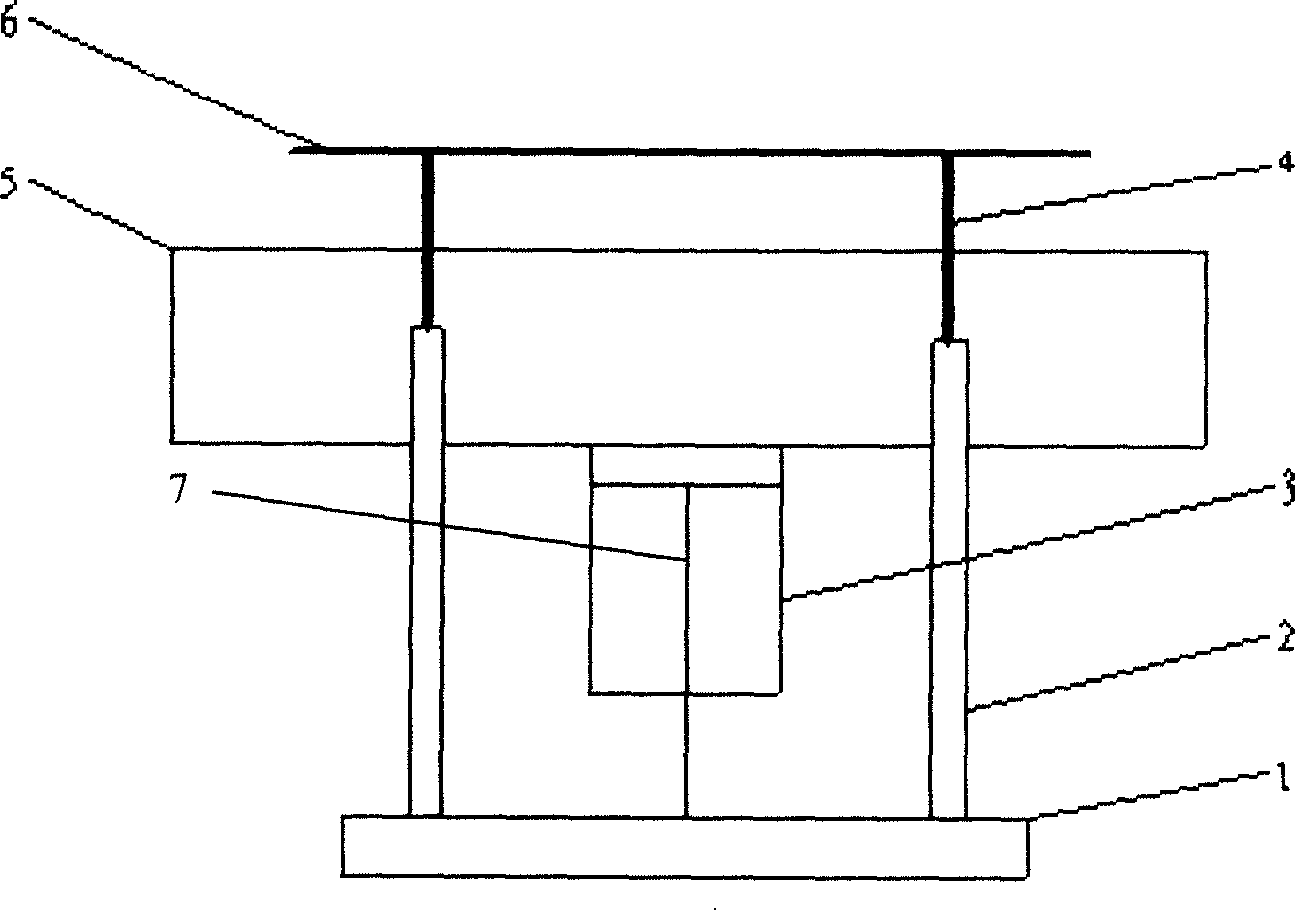

Control apparatus for eliminating reversing shake of dbl act gas cylinder

A double-acting cylinder and control device technology, applied in the direction of fluid pressure actuators, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of chip 6 out of position, adverse consequences, etc., to eliminate jitter, eliminate rapid expansion and contraction, The effect of meeting the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

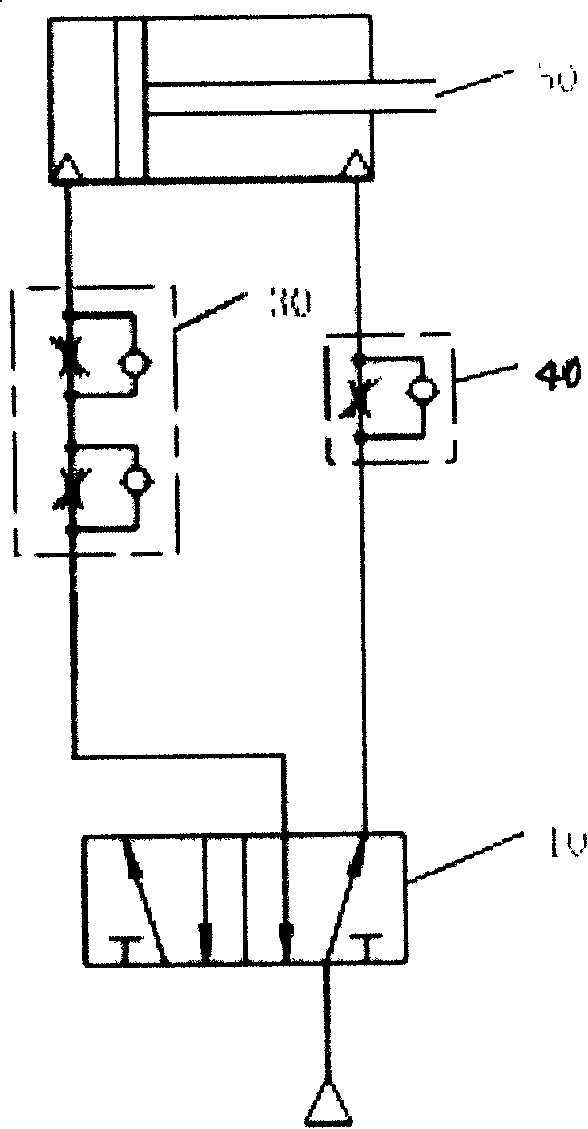

[0027] The control device for eliminating the reversing vibration of the double-acting cylinder provided by the present invention is an improvement on the prior art, such as image 3 As shown, the air inlet of the two-position five-way solenoid valve 10 as a reversing valve is connected to the air source, and an outlet of the two-position five-way solenoid valve 10 is connected with a two-way speed regulating valve 30, and the two-way speed regulating valve 30 The other end is connected to an intake port of the double-acting cylinder 50 . When the wafer is transferred from the highest position to the lowest position, the air flow flows out from an outlet of the two-position five-way solenoid valve 10 and enters the rodless chamber of the double-acting cylinder 10 through the two-way speed regulating valve 30. In order to prevent the double-acting cylinder 50 from starting When the piston rod of the cylinder "extends rapidly", the flow rate of the air flow in the pipeline can b...

Embodiment 2

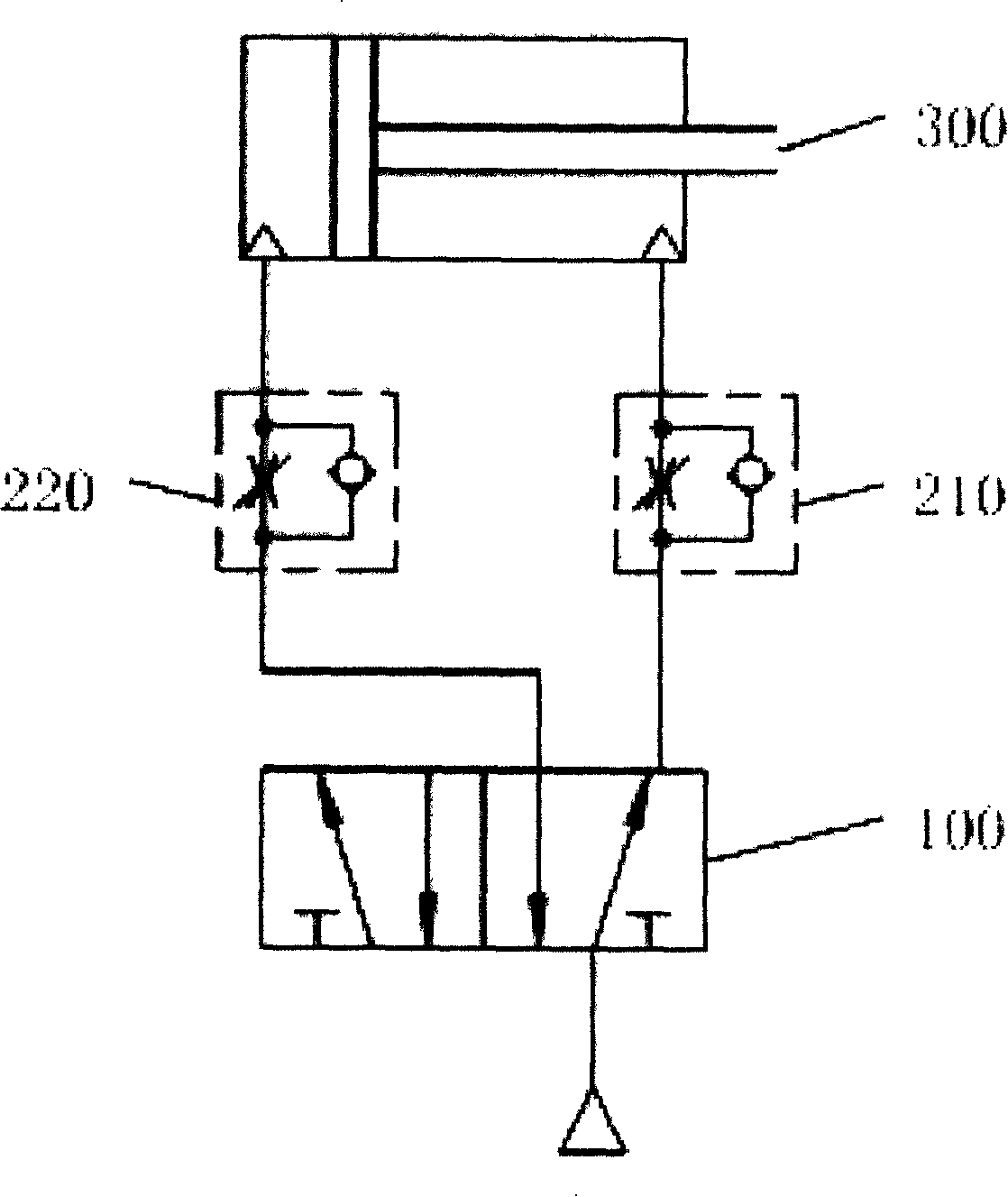

[0030] This example is a preferred embodiment of the present invention. In order to ensure that the operation process of the double-acting cylinder is stable and the operation time can meet the requirements, a speed change device is added to the control device, such as Figure 4 As shown, in the control air circuit of the wafer lifting device in the first embodiment, a transmission device is added, and the transmission device includes two first two-position two-way solenoid valves 21 and second two-position two-way solenoid valves 22. One two-position two-way solenoid valve 21 is installed on the air pipeline provided with a two-way speed regulating valve 30, and is connected in series with the two-way speed regulating valve 30, and the second two-position two-way solenoid valve 22 is connected in parallel with the two-way speed regulating valve 30 and the two-way speed regulating valve 30 connected in series. The two ends of the first two-position two-way solenoid valve 21. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com