Method and device for alignment and assembly of glass micro nanofluidic chip

A nanofluidic and glass-micro technology, which is applied in the field of glass micro-nanofluidic chip alignment and assembly, can solve the problems of high cost and achieve the effect of reducing manufacturing cost and difficulty, simple operation, precise and fast alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

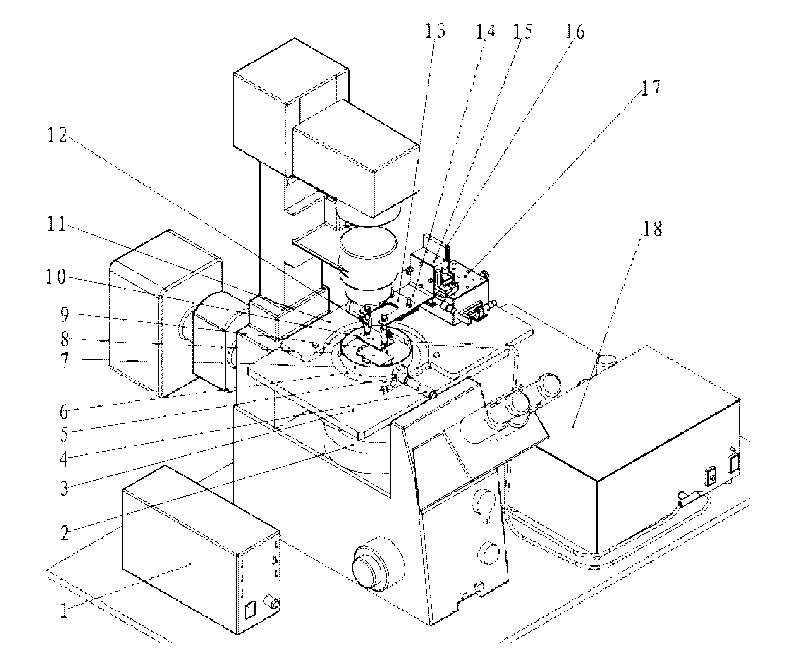

[0027] Embodiment 1: Three-dimensional micro mobile platform device

[0028] combined with figure 1 The configuration of the three-dimensional micro mobile station device according to the present invention will be described. The three-dimensional micro-moving device is mainly composed of a spiral measuring micrometer head 4, a spiral measuring micrometer head mounting seat 5, a cover plate 6, a chip container 7, a magnetic strip 9, a connecting plate 11, a vacuum chuck 12, a vacuum chuck mounting plate 13, and a right-angle plate 14 , a manual one-way micro-moving platform 15, a right-angle mounting plate 16, a manual two-way micro-moving platform 17 and the like. Install the spiral micrometer sub-head 4 on the spiral micrometer sub-head mounting base 5, then fix the installed spiral micrometer sub-head mounting base 5 together with the connecting plate 11 on the microscope stage 3, and put the cover plate 6 on the microscope In the circular groove corresponding to the stage...

Embodiment 2

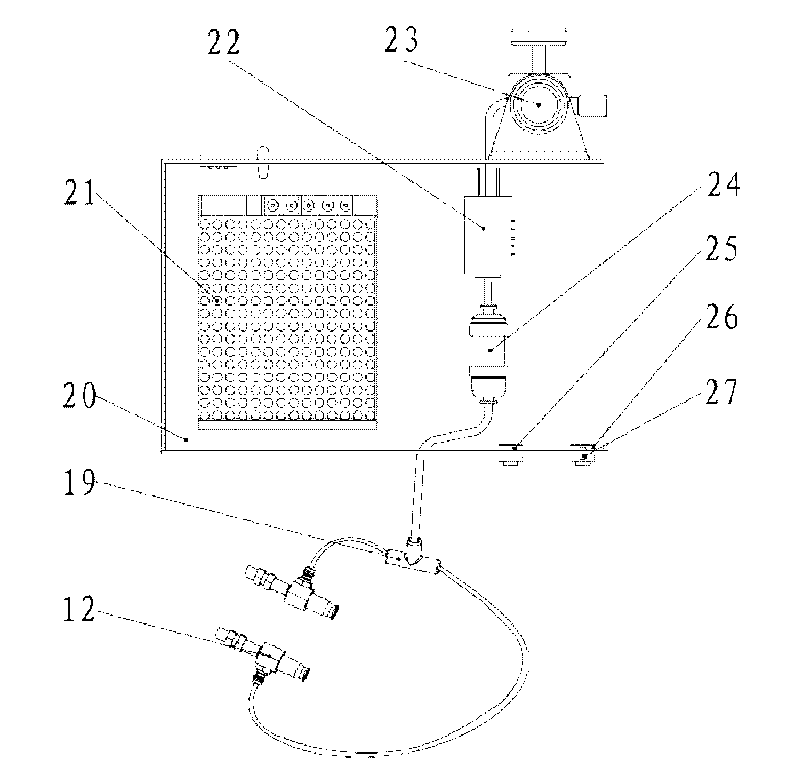

[0029] Embodiment 2: vacuum adsorption device

[0030] combined with figure 2 The structure of the vacuum adsorption apparatus concerning this invention is demonstrated. The vacuum adsorption device is mainly composed of a T-shaped connecting pipe 19, a box body 20, a DC power supply 21, a three-way solenoid valve 22, a vacuum air-conditioning valve 23, a vacuum filter 24, a power switch 25, a three-way solenoid valve switch 26, an indicator light 27, Vacuum pump 28 etc. are formed. Fix the DC power supply 21, the three-way electromagnetic valve 22, and the vacuum filter 24 on the bottom panel of the casing 20, and fix the vacuum pressure valve 23 on the rear panel of the casing 20 so that it is outside the casing 20, In order to check and adjust the vacuum pressure, a power switch 25, a three-way solenoid valve switch 26 and an indicator light 27 are fixed on the front panel of the box body 20 for easy operation by the operator.

Embodiment 3

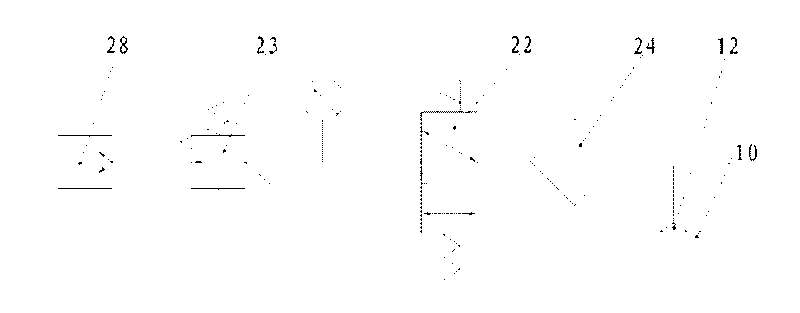

[0031] Embodiment 3: the adsorption of vacuum adsorption device

[0032] combined with image 3 The adsorption principle of the vacuum adsorption device according to the present invention will be described. Connect the vacuum pump 28, the vacuum air-conditioning valve 23 with the vacuum pressure gauge, the three-way solenoid valve 22, the vacuum filter 24, the T-shaped connecting pipe 19, and the vacuum chuck 12 in sequence with a flexible pipe. When the vacuum pump 28 is turned on, the three-way electromagnetic valve 22 is closed, and the air circuit with the vacuum chuck 12 is connected with the normal port of the three-way electromagnetic valve 22, and is connected to the atmosphere. When the three-way solenoid valve 22 is opened, the vacuum pump 28 is connected to the vacuum chuck 12 along the air path, and the vacuum chuck 12 can be used to suck the chip at this moment. After completing the operation, close the three-way electromagnetic valve 22, and now the vacuum chuc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com