Production method of porous shell

A manufacturing method and shell technology, applied in anodic oxidation, etc., can solve the problems of inaccurate opening, inability to mass produce, slow speed, etc., and achieve the effects of improving wear resistance, improving production efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

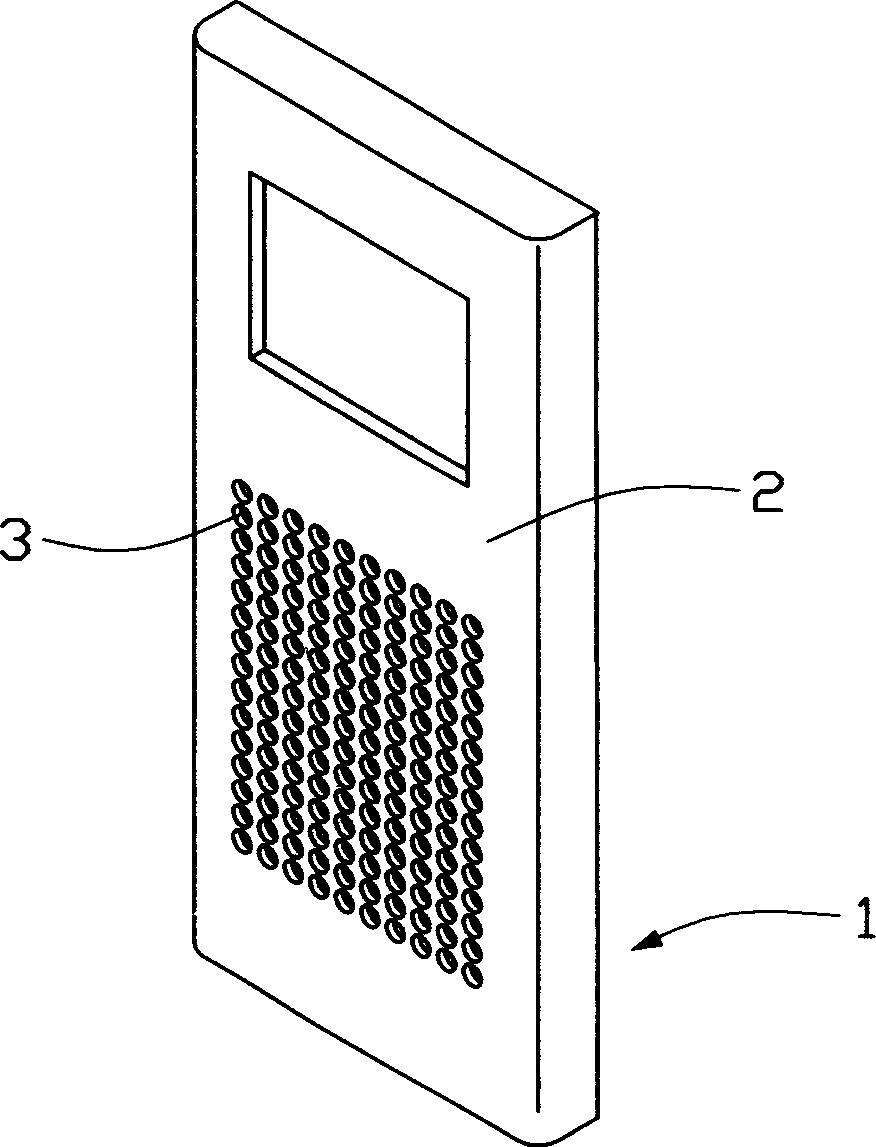

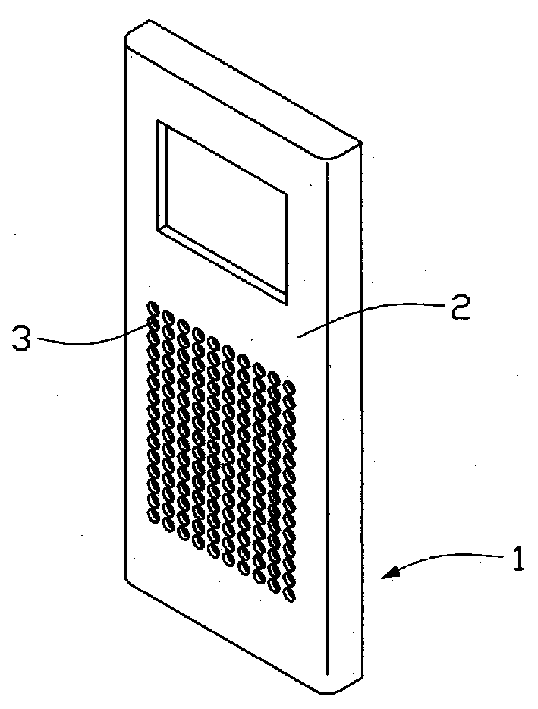

[0007] In this embodiment, the method of manufacturing the porous housing is specifically described by taking the manufacturing of a porous housing of a portable electronic device as an example. Please refer to figure 1 The porous shell 1 includes a base 2 with a honeycomb-shaped through hole 3, and the through hole 3 is circular. The substrate 2 is a metal substrate with an anodic oxide film on its surface. The anodic oxide film can be colored in various colors as needed, and patterns can also be formed on the surface.

[0008] Manufacturing the above-mentioned porous shell 1 mainly includes the following steps:

[0009] (1) Punching;

[0010] (2) Stamping and forming;

[0011] (3) Grinding;

[0012] (4) Anodizing.

[0013] Among them, step (1) is to continuously punch the metal sheet through several punching stations. Each station is provided with at least one punching machine, each punching machine is provided with at least one punching die, and the upper die of each punching d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com