Device for assembling rock samples in true triaxial test

A true triaxial, rock sample technology, applied in the field of rock sample assembly devices in true triaxial tests, can solve problems such as loading center deviation, test result distortion, troublesome operation, etc., to achieve easy smearing and drying, simple operation, The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

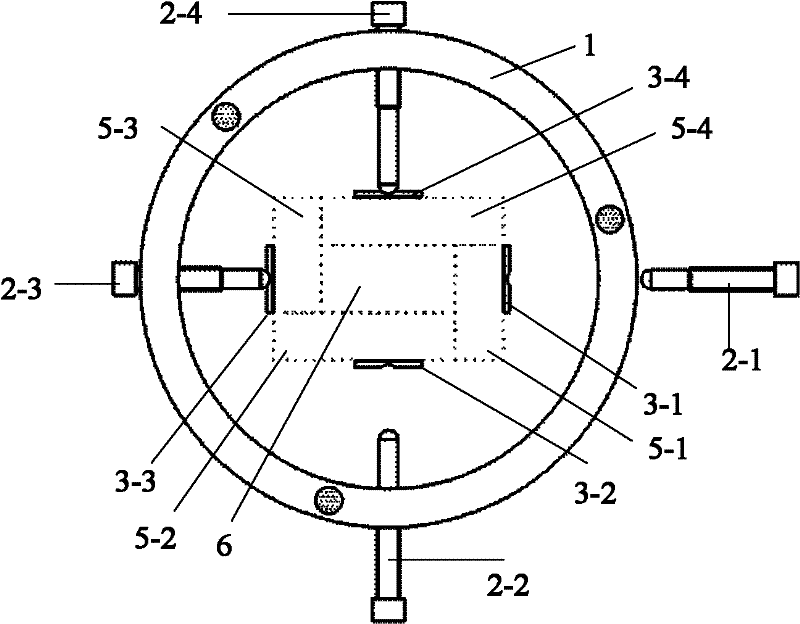

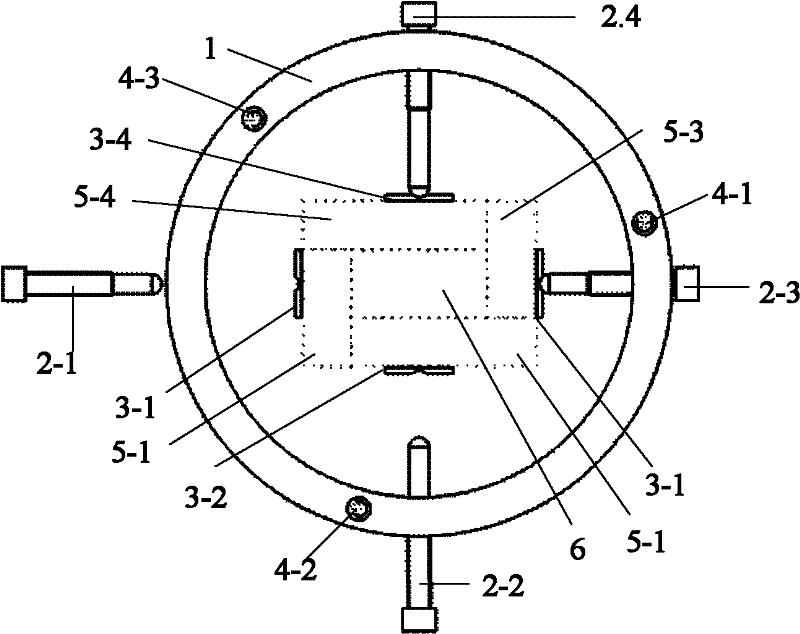

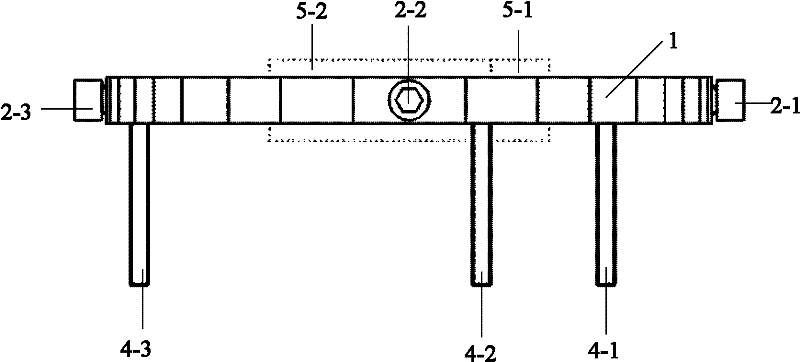

[0028] A device for assembling rock samples in a true triaxial test, the device includes a ring frame 1, a first locking bolt 2-1, a second locking bolt 2-2, a third locking bolt 2-3, The fourth locking bolt 2-4, the first disc washer 3-1, the second disc washer 3-2, the third disc washer 3-3, the fourth disc washer 3-4 and the first A support screw 4-1, a second support screw 4-2, and a third support screw 4-3. according to figure 1 , 2 , 3, the connection relationship is: the ring frame 1 has two pairs of orthogonal screw holes in the horizontal direction, the central axis of each pair of screw holes passes through the center of the ring frame 1, and two pairs of first locking bolts 2-1, The second locking bolt 2-2, the third locking bolt 2-3, and the fourth locking bolt 2-4 are respectively screwed in the horizontal screw holes of the ring frame 1; the first locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com