A true triaxial seepage characteristics and strength test device for large-scale soil samples

A strength test, true triaxial technology, applied in the direction of measuring device, using stable tension/pressure test material strength, permeability/surface area analysis, etc., can solve the problem of inability to truly reflect the soil strength and seepage characteristics, and the deviation of test results , the small size of the test soil sample, etc., to achieve the effects of reducing the influence of boundary effects, widening the research range, and improving the test stress level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

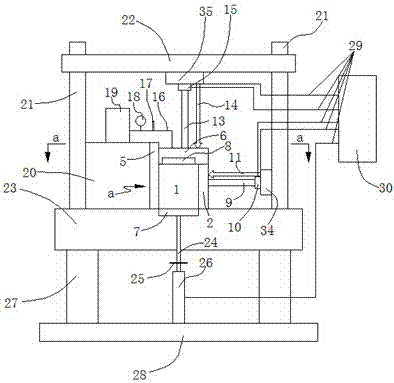

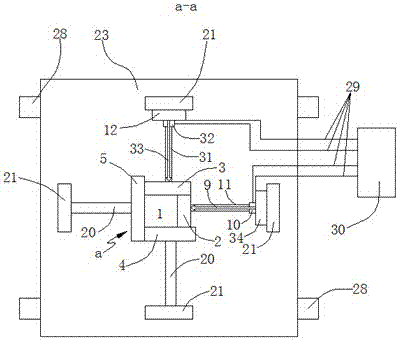

[0025] see Figure 1-2 , it comprises frame, and this frame is made up of test frame base 28 that is arranged parallel to each other, rigid test pressurized platform 23 and rigid pressurized reaction frame crossbeam 22, wherein, described test frame base 28 and rigid test pressurized The platforms 23 are connected and fixed by the base column 27, and the rigid test pressurized platform 23 and the rigid pressurized reaction frame crossbeam 22 are connected and fixed by four rigid pressurized reaction frame columns 21 respectively located at its four sides , the pressure chamber a is set on the rigid test pressurized platform 23;

[0026] The pressure chamber a includes an earth pressure chamber y-directed fixed side plate 4 and an adjacent earth pressure chamber x-directed fixed side plate 5, and the earth pressure chamber y-directed fixed side plate 4 and the earth pressure chamber x-directed The fixed side plates 5 are respectively fixed on the columns 21 of the rigid pressu...

Embodiment 2

[0034] When carrying out the true triaxial strength test of large-scale soil samples, put the soil sample 1 into the rubber mold (drainage and seepage tests put the soil sample into the rubber membrane with the lower opening, and the undrained test put the soil sample into the rubber membrane with the lower part closed). film), and then put it on the bottom permeable stone 7, start the x-direction horizontal pressure plate driver 9 and the y-direction horizontal pressure plate driver 31 to respectively drive the x-direction laterally shrinkable pressure plate 2 and the y-direction laterally retractable The pressure plate 3 is in close contact with the side surface of the sample 1, and then the vertical pressure driver 13 is started to make the top pressure plate 6 contact the upper surface of the soil sample 1, and the x-direction deformation tester 11 and the y-direction deformation tester 11 are adjusted. Instrument 33 and vertical deformation tester 14 make it in good contac...

Embodiment 3

[0036] When carrying out a triaxial test with different water contents and equal confining pressure on a large-scale soil sample, first drive the x-direction horizontal pressure plate driver 9, the y-direction horizontal pressure plate driver 31 and the vertical pressure driver 13 simultaneously to make the three-way pressure When the same value is reached, soil sample 1 is consolidated under hydrostatic pressure. After the consolidation is completed, the vertical presser 13 is turned on to drive the top presser plate 6 until the soil sample 1 reaches the failure condition, and the deformation and stress of the soil sample 1 are recorded by the data acquisition system 30 during the whole process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com