Thick-walled pipe lateral induction straight seam welding device and method

A technology of straight seam welding and induction heating device, used in welding equipment, welding equipment, auxiliary devices, etc., can solve the problem that induction heating cannot be widely used, the temperature distribution of the side wall of the welding seam is uneven, and the straight seam welding of thick-walled pipes is impossible. and other problems, to achieve the effect of solving uneven heating, uniform heating and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise. Is, unless otherwise noted, technical and scientific terms used herein should be understood by those skilled in the usual sense of the present invention should be noted. The present invention is used, for example, the front, rear, left, and right are merely exemplary in nature, are terms used for convenience of description.

[0034] The technical solutions of the present invention are further specifically described below by way of examples and in connection with the accompanying drawings.

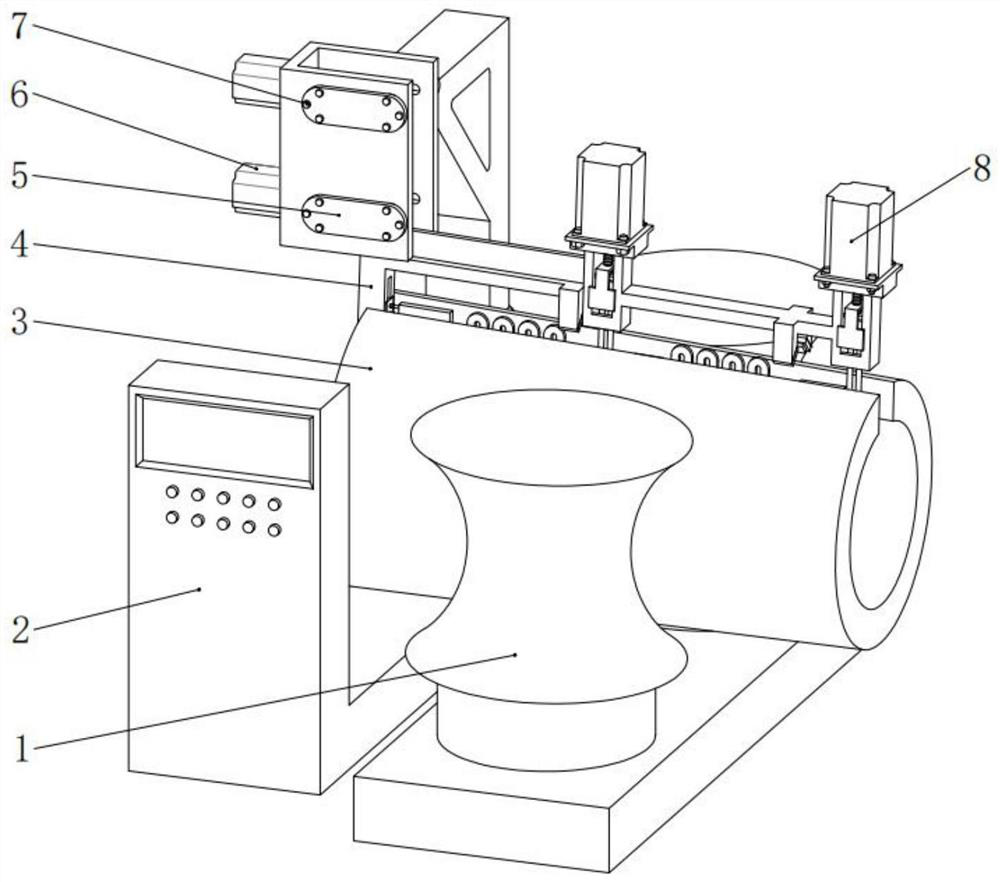

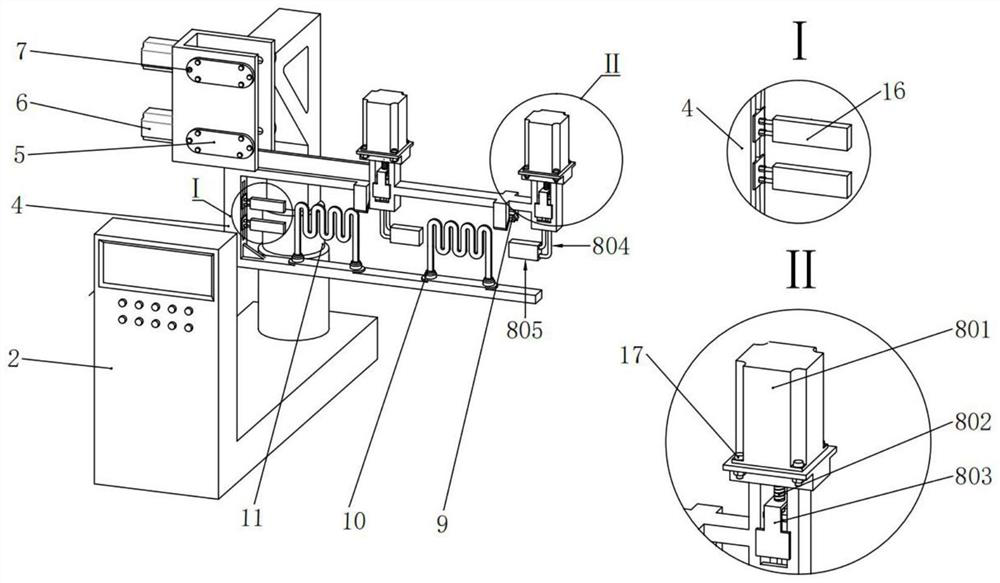

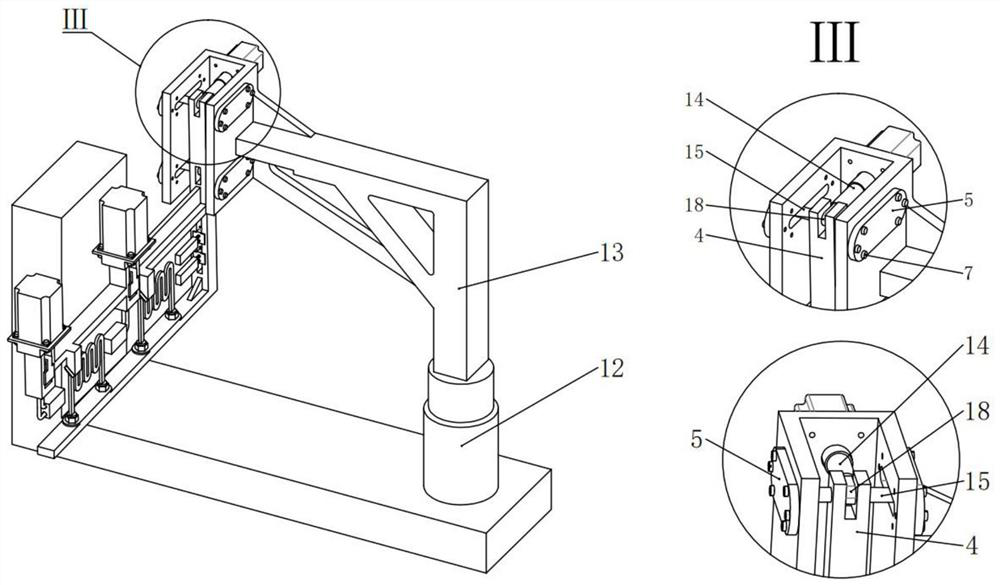

[0035] like Figure 1 - Figure 7 , The induction welding apparatus Longitudinal thick pressed in a platen roller and pushes the transmission tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com