Prefabricated continuum model box for simulating underground structure under combined action of fault and seismic oscillation

A technology of underground structure and model box, applied in the test of basic structure, test of machine/structural components, basic structure engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is attached Figure 1-9 , to illustrate specific embodiments of the present invention.

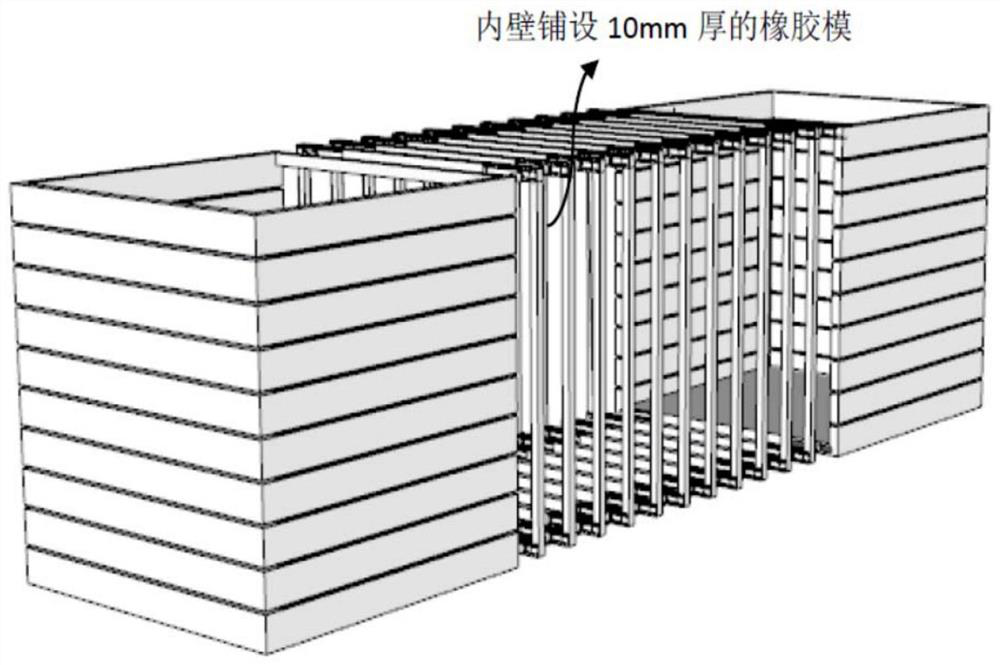

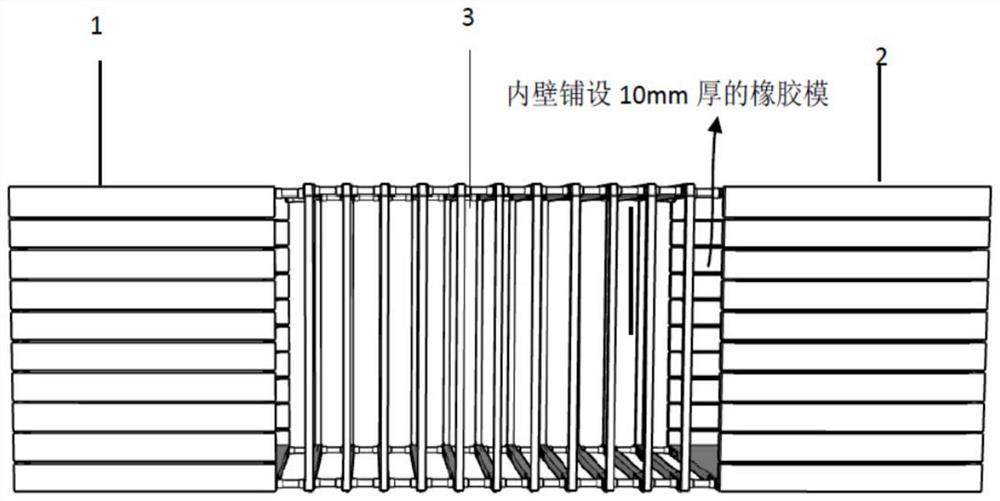

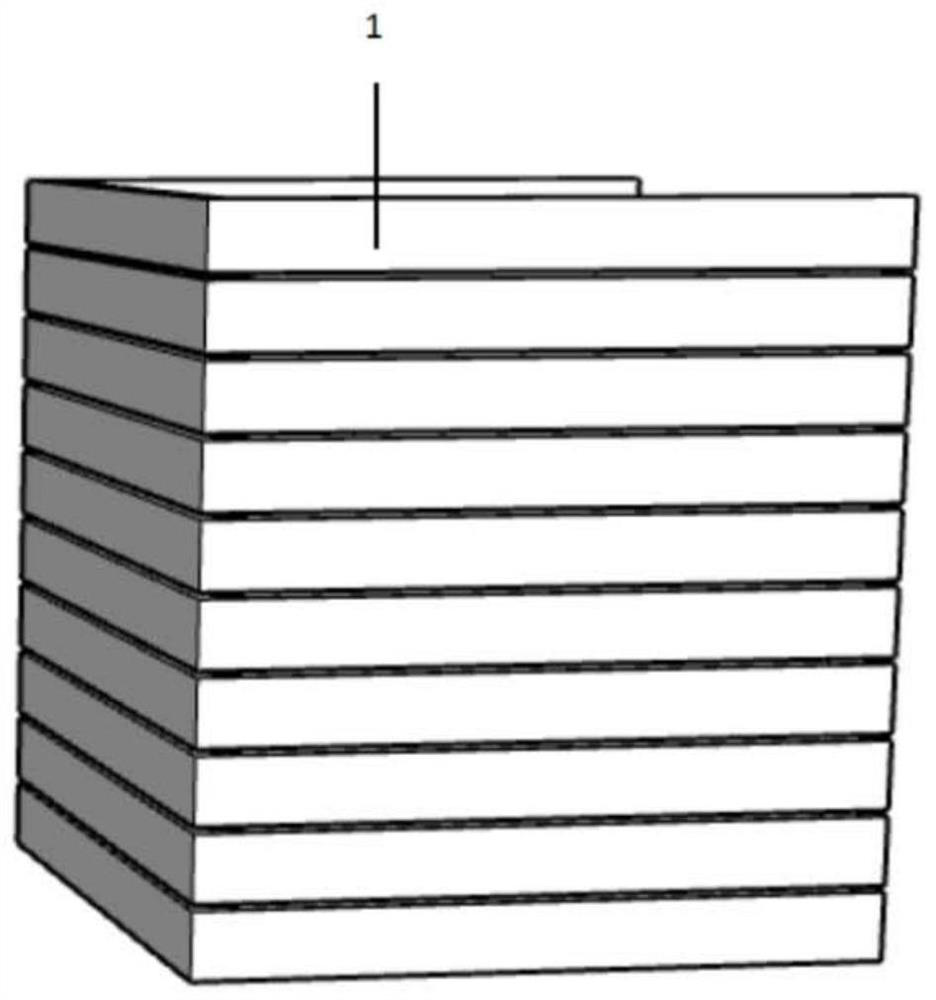

[0029] A multi-array shaking table model test device for an underground structure, installed on a shaking table, including a first end box 1, a second end box 2, a middle box 3, a sliding ball joint 4, a hinge device 5, and a slide rail 6.

[0030] The bottoms of 1 and 2 of the end box are connected with the vibrating table by bolts, and several holes are arranged on the bottom of the end box.

[0031] The end boxes 1 and 2 are composed of U-shaped frames stacked up and down, and the layers are connected by slide rails 6 to simulate horizontal shearing of soil. The slide rail 6 is composed of upper and lower parts spliced together, and is connected with the U-shaped frame by bolts. A number of bolt holes are reserved in the bottom of the slide rail 6, and the maximum shear displacement of the soil can be artificially limited by installing bolts in the bolt holes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com