Explosive welding device and method

A technology of explosive welding and electric explosion, applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve problems such as poor welding quality of explosive welded composite plates, avoid welding quality problems, improve welding effect, and reduce plate waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

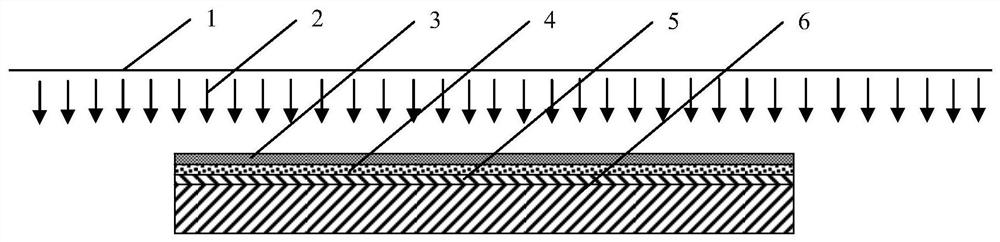

[0042] like figure 1 As shown, the object to be welded in this embodiment is the doubler plate 5, and the main explosive is laid on the surface of the doubler plate 5 to form the main explosive layer 4; then the photosensitive explosive is coated on the surface of the main explosive layer 4 to form a photosensitive explosive coating 3. Applying explosives can be done remotely by a spray robot or robotic arm.

[0043]When explosively welding plates, the metal wire 1 undergoes an electric explosion under the action of a strong current to generate strong light 2, and the strong light 2 irradiates the photosensitive explosive coating 3 coated on the surface of the main explosive layer 4, so that the photosensitive explosive coating 3 is completely coated. The layer explodes at the same time, and generates a detonation wave to detonate the main explosive layer 4 on the lower side. The main explosive layer 4 on the lower side detonates at the same time and acts on the doubler plate...

Embodiment 2

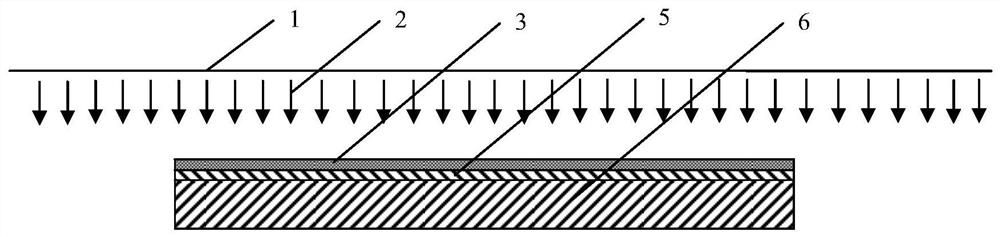

[0045] The difference from Embodiment 1 is that this embodiment does not include a main explosive layer.

[0046] like figure 2 As shown, when explosively welding plates, the metal wire 1 undergoes an electric explosion under the action of a strong current to generate strong light 2, and the strong light 2 irradiates the photosensitive explosive coating 3 coated on the surface of the double board 5, so that the photosensitive explosive coating 3 The entire coating surface explodes at the same time and acts on the doubler plate 5, causing the doubler plate 5 to hit the base plate 6 to achieve the purpose of welding. One or more metal wires 1 can be used as the light source of the strong light 2 to ensure uniform illumination of the photosensitive explosive coating 3 and improve the discharge energy of the detonating device to ensure the synchronization of large-area detonation of the photosensitive explosive 3; A certain gap is set between 5 and the substrate 6, and the two c...

Embodiment 3

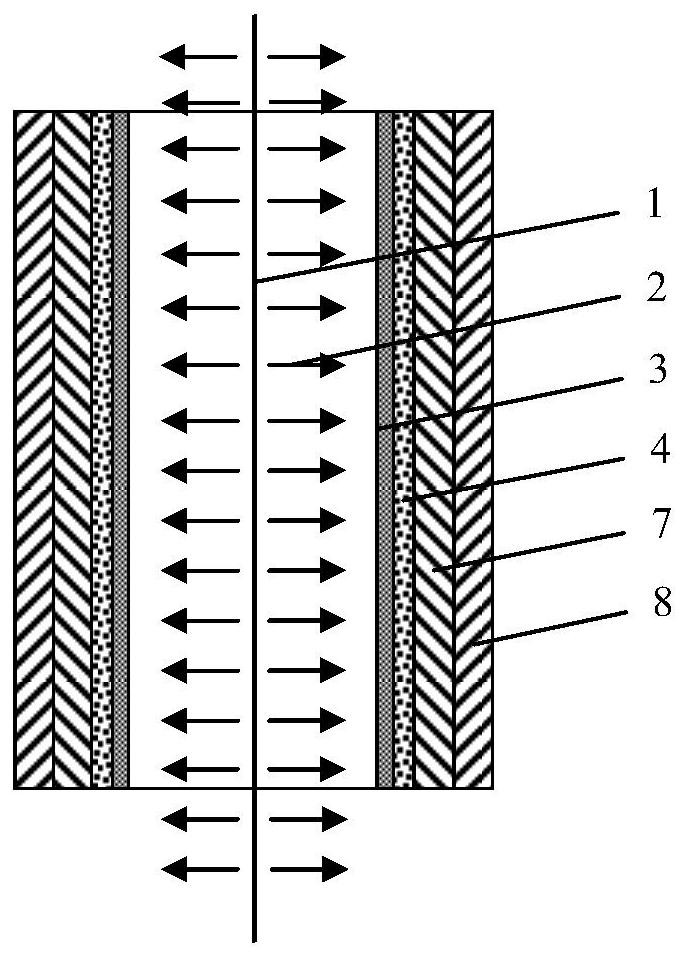

[0048] like image 3 As shown, the welding target of the present embodiment is a multiple tube 7, and the main explosive layer 4 is laid on the inner surface of the multiple tube 7, and then the surface of the main explosive layer 4 is coated with a photosensitive explosive to form a photosensitive explosive coating 3. The metal wire 1 is placed in the multiple tube 7 .

[0049] When explosively welding pipes, the metal wire 1 undergoes an electric explosion under the action of a strong current to generate strong light 2, and the strong light 2 irradiates the photosensitive explosive coating 3 coated on the surface of the main explosive layer 4, so that the photosensitive explosive coating 3 is completely coated. Layers explode simultaneously, and generate detonation waves to detonate the outer main explosive layer 4, and the outer main explosive layer detonates at the same time and acts on the multiple tube 7, causing the multiple tube 7 to hit the base tube 8 to achieve the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com