Method for testing air shrinkage resistant performance of plastering material

A plastering material and ability testing technology, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., to achieve the effect of smooth surface, simple and easy method, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

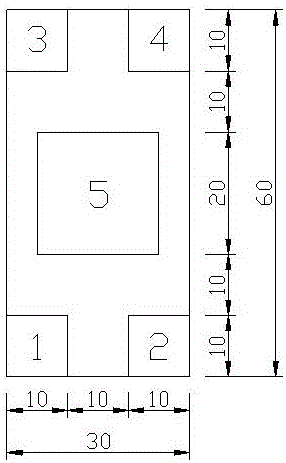

Method used

Image

Examples

example 1

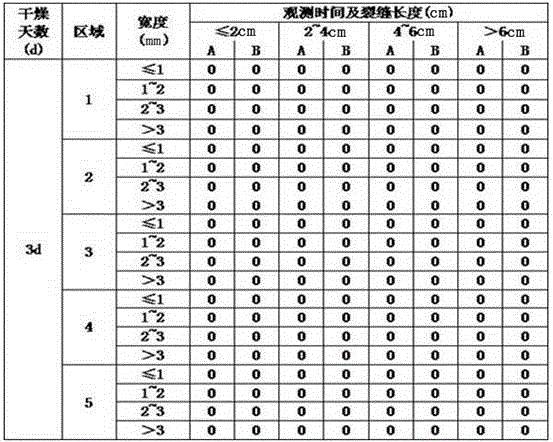

[0040] Observation table for the number of cracks recorded when a layer of plastering material is dried for 3 days:

[0041] Crack Quantity Observation Table (3d)

[0042]

[0043] The number of cracks recorded when the plastering material layer is dried for 7 days is as follows:

[0044] Crack Quantity Observation Table (7d)

[0045]

[0046] The observation table of the number of cracks recorded when the plastering material layer was dried for 14 days:

[0047] Crack Quantity Observation Table (14d)

[0048]

[0049] The number of cracks recorded in the plastering material layer when the number of drying days is 28 days:

[0050] Crack Quantity Observation Table (28d)

[0051]

[0052] In the above tables, Group A is the record at 8:00, and Group B is the record at 20:00.

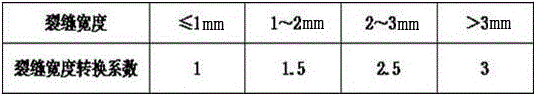

[0053] Use the crack width conversion coefficient table and the following formula to calculate the number of cracks and fill them in to form the following summary table:

[0054] Statist...

example 2

[0057] Take another observation table for the number of cracks recorded when a plastering material layer is dried for 3 days:

[0058] Crack Quantity Observation Table (3d)

[0059]

[0060] The number of cracks recorded when the plastering material layer is dried for 7 days is as follows:

[0061] Crack Quantity Observation Table (7d)

[0062]

[0063] The observation table of the number of cracks recorded when the plastering material layer was dried for 14 days:

[0064] Crack Quantity Observation Table (14d)

[0065]

[0066] The number of cracks recorded in the plastering material layer when the number of drying days is 28 days:

[0067] Crack Quantity Observation Table (28d)

[0068]

[0069] In the above tables, Group A is the record at 8:00, and Group B is the record at 20:00.

[0070] Use the crack width conversion coefficient table and the following formula to calculate the number of cracks and fill them in to form the following summary table:

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crack width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com