Global shaping mould and method of titanium alloy air inlet part

A technology of integral forming and air inlet, applied in the field of sheet metal and hot processing, can solve the problems of difficult cold forming, low efficiency, large deformation resistance, etc., to achieve the effect of stable placement and forming, and reducing the depth of the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following describes the present invention in detail with reference to the drawings and embodiments:

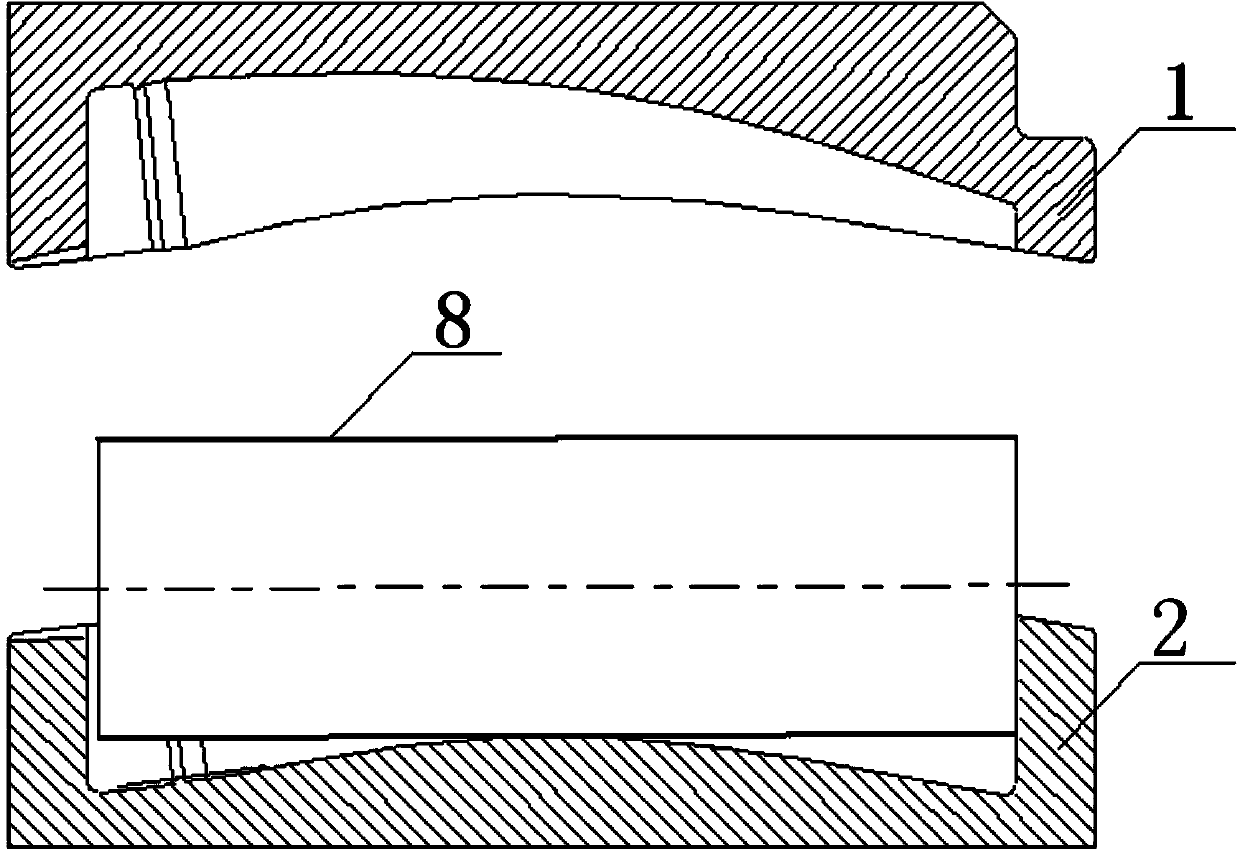

[0017] Titanium alloy parts are a kind of special-shaped curved thin-wall parts with shapes and sizes such as Figure 4 As shown, in order to reduce the depth of the mold cavity, facilitate the stable placement and forming of the blank, and facilitate the smooth removal of the mold after the mold is opened, it is determined that the process parts are deflected by 7°. Take the largest cross section of the process part as the parting surface to design the superplastic forming mold.

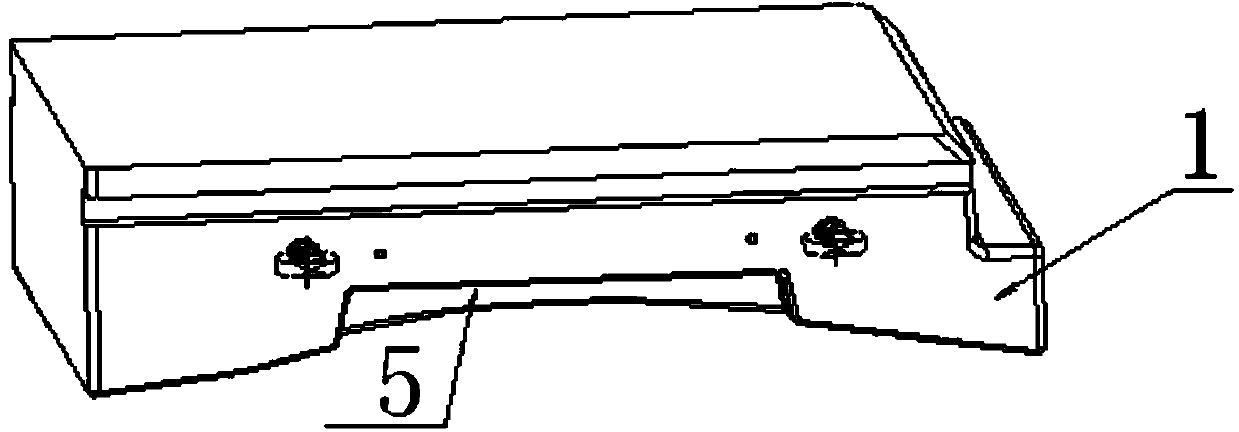

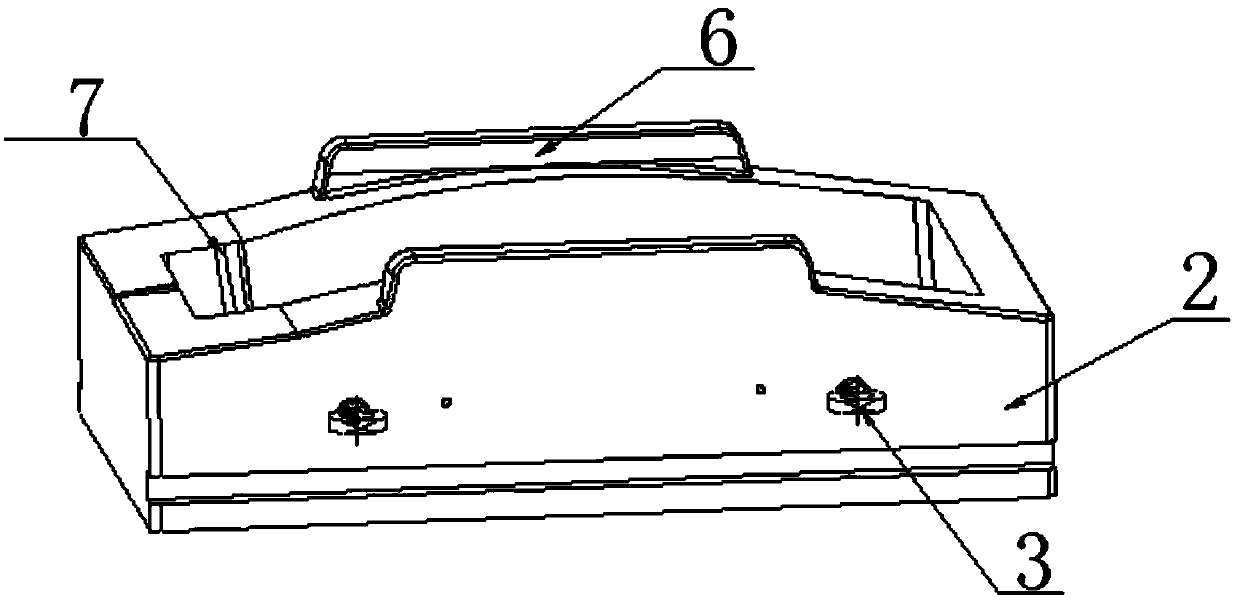

[0018] figure 1 with figure 2 It is a schematic diagram of an upper mold and a lower mold of an integral forming mold for titanium alloy air inlet parts. The mold includes an upper mold 1 and a lower mold 2. Two lifting screws 3 are provided on the upper mold 1 and the lower mold 2. A guide groove 5 is opened at the lower part of the upper mold 1, a guide boss 6 is provided on the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com