Gas electric vertical-position welding tray-free arc welding method for vertical-seam welding

A gas-electric vertical welding and gas-electric vertical technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of molten metal leakage, inconsistent weld quality, poor appearance and other problems, and achieve the improvement of construction progress, The effect of saving manpower and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

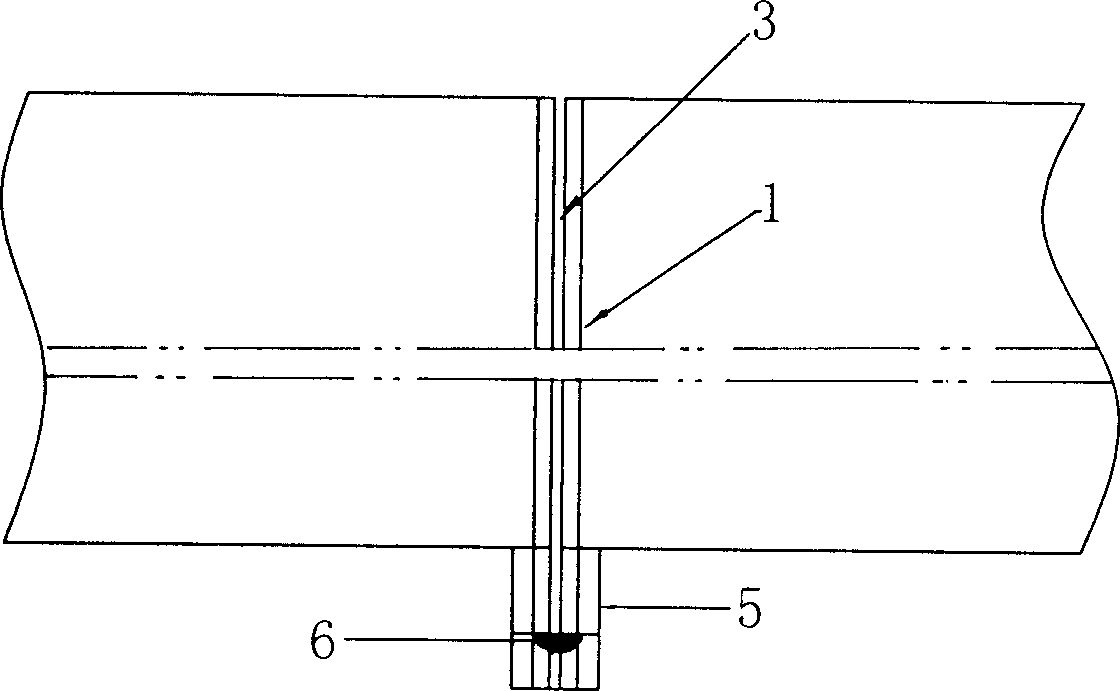

[0031] Such as figure 2 shown.

[0032] A gas-electric vertical welding without backing arc-starting welding method for vertical seam welding, which is formed by one-time welding with a gas-electric vertical welding machine. It mainly includes three processes: arc starting, normal welding, and cleaning. The welding machine is automatic, and the specific welding method is as follows:

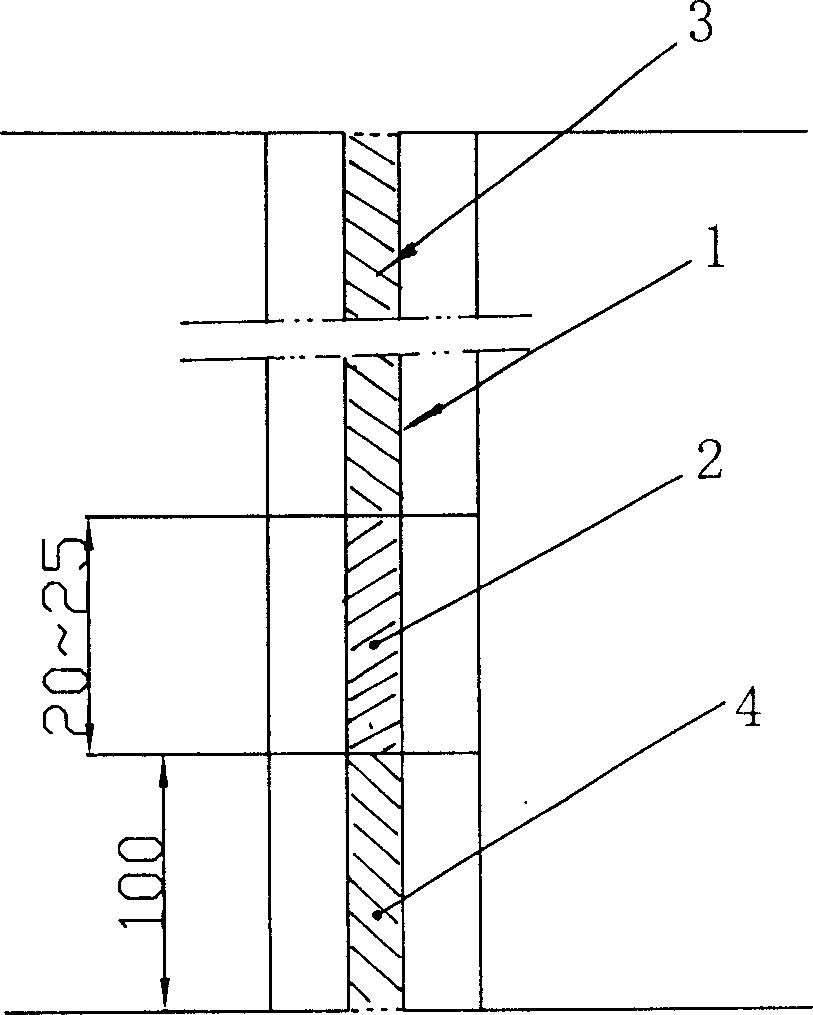

[0033] Step 1, weld an arc starting plate 6 with the same groove size as the vertical welding groove at the lower part of the vertical seam arc starting point without a circular seam;

[0034] Step 2, install the liner copper pad and the sliding water-cooled copper backing plate of the gas-electric vertical welding at the arc start of the vertical seam 1 to be welded;

[0035] The third step is to control the welding specification so that it transitions from the small specification to the normal specification one by one, and adopts interrupted arc welding within the scope of the small specific...

Embodiment 2

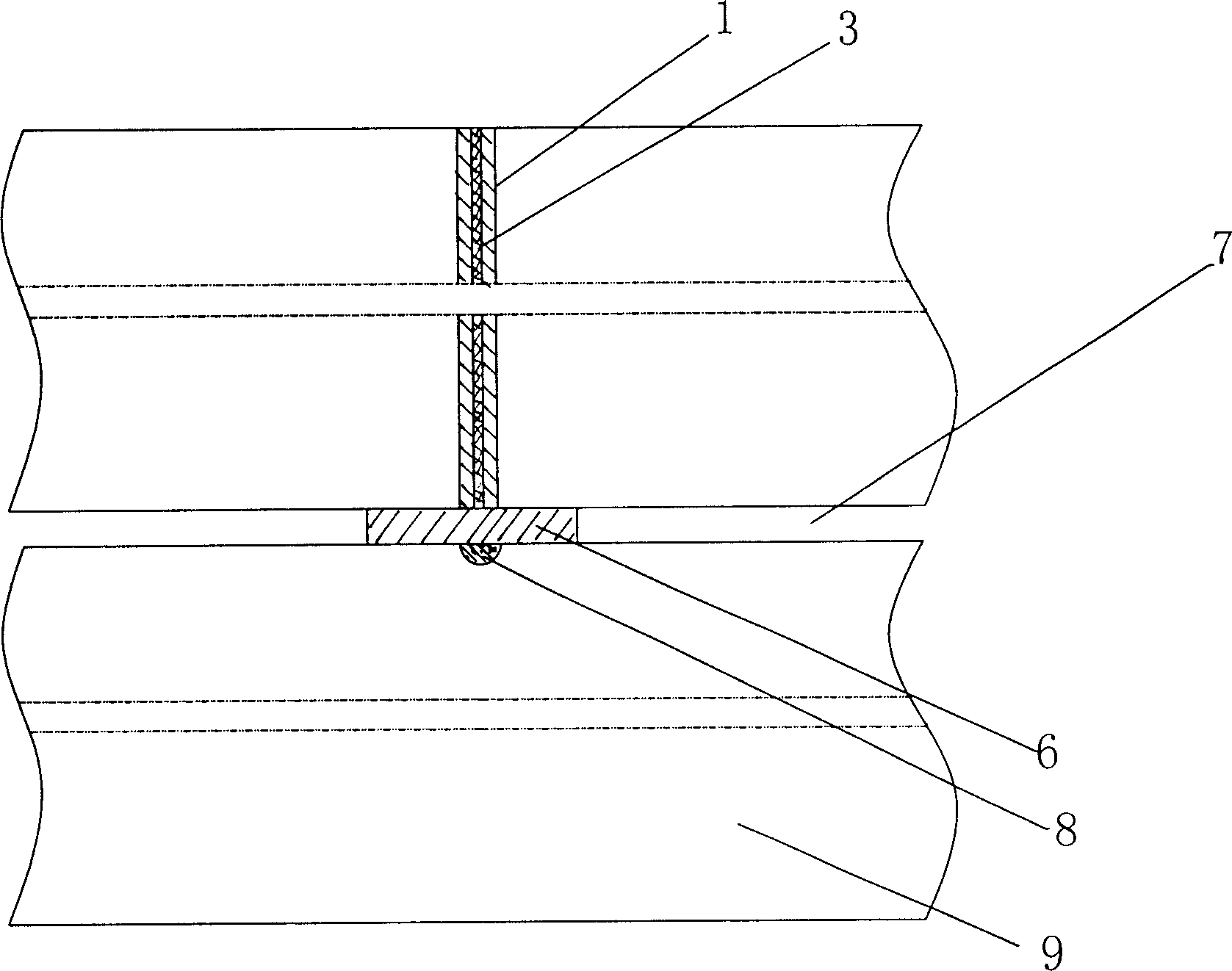

[0039] Such as image 3 shown.

[0040] A gas-electric vertical welding without backing arc-starting welding method for vertical seam welding, which is formed by one-time welding with a gas-electric vertical welding machine. It mainly includes three processes: arc starting, normal welding, and cleaning. The welding machine is automatic, and the specific welding method is as follows:

[0041] Step 1, on the circular seam 7 (formed by the vertical seam steel plate to be welded and the lower steel plate 9) at the junction with the arc starting point of the vertical seam 1, the circular seam groove of the part blocked by the water-cooled block is welded with an electrode arc welding It is full to obtain a process weld 6 with a welding length of 5-10 mm, and the weld is polished smooth;

[0042] Step 2, install the liner copper pad and the sliding water-cooled copper backing plate of the gas-electric vertical welding at the arc start of the vertical seam to be welded;

[0043] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com