Joining components by means of resistance welding

A technology of resistance welding and components, which is applied in the direction of resistance welding equipment, welding equipment, resistance electrode holders, etc., and can solve the problems of the necessity of multiple welding stations in a large takt time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

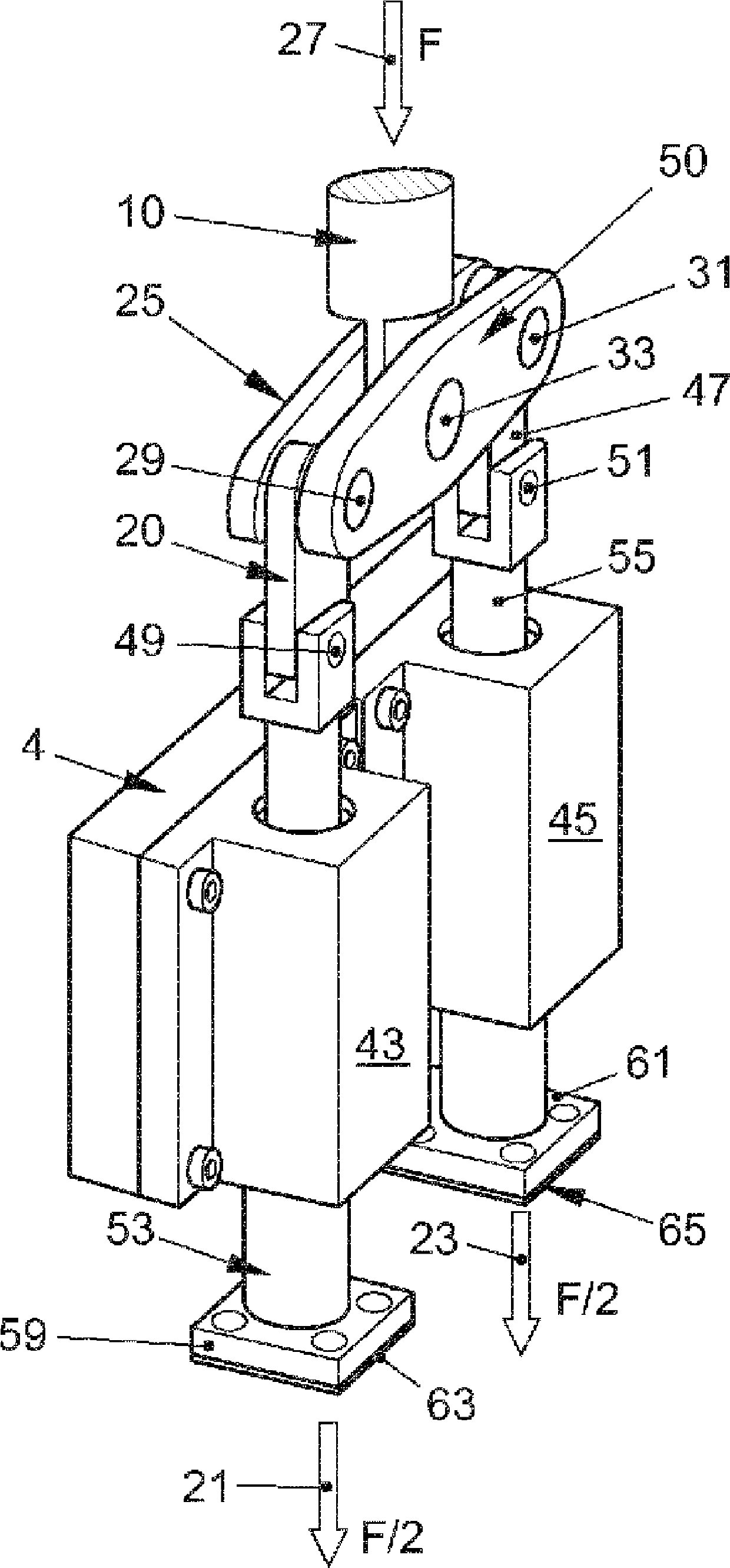

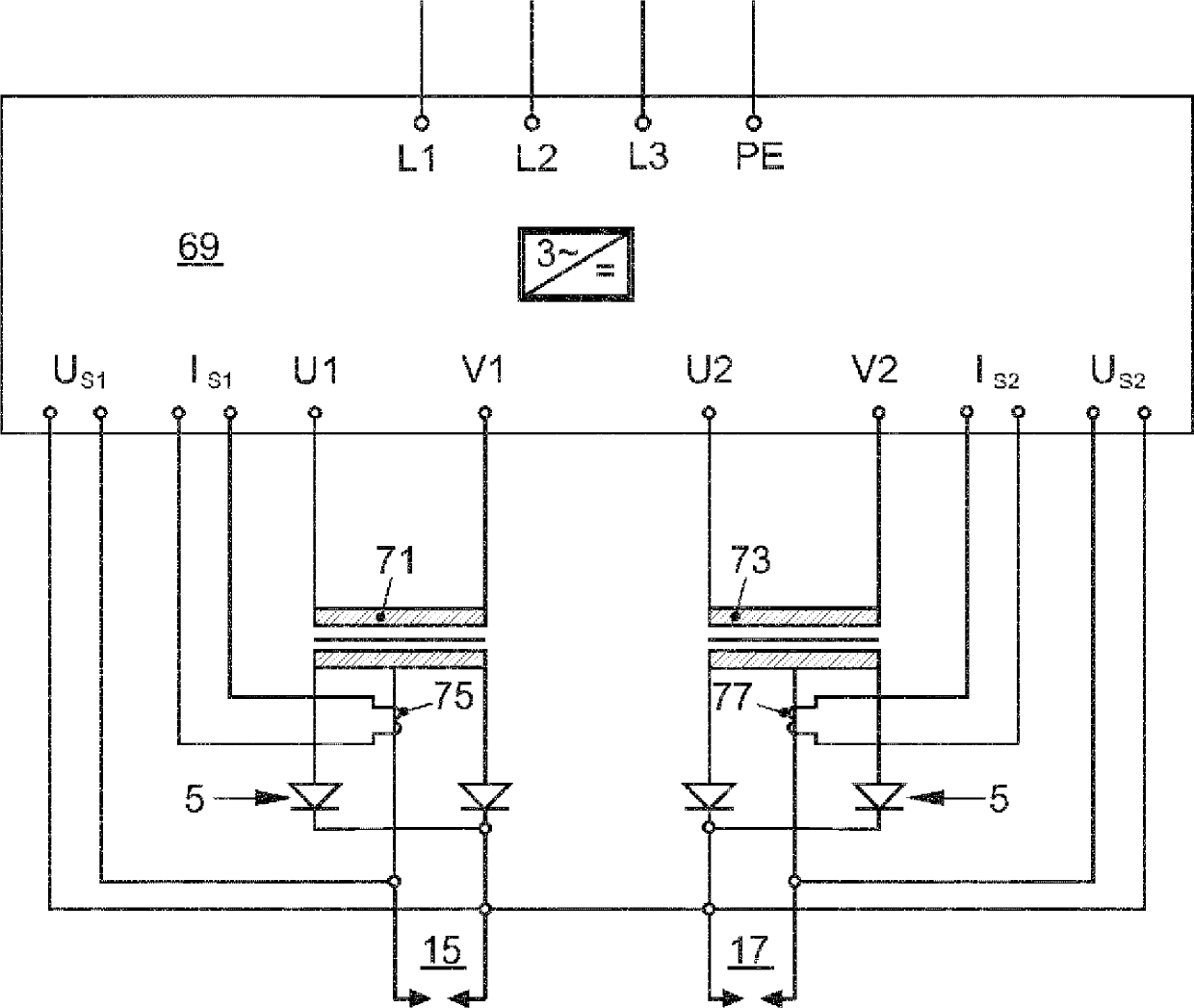

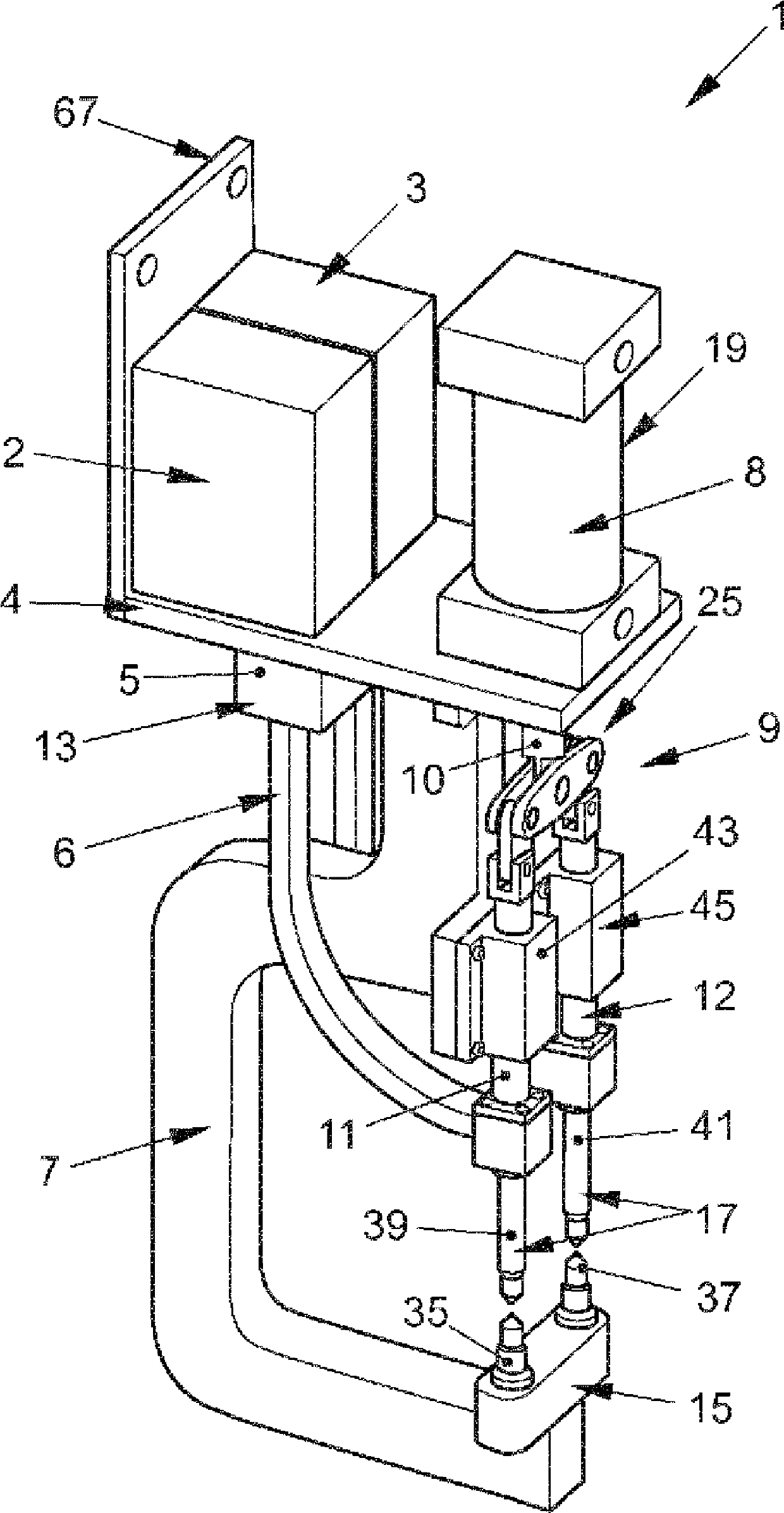

[0025] figure 1 A three-dimensional view of the C-Bügel (C-Bügel) 7 of the welding device 1 is shown diagonally from the front and above. The welding device 1 has an electrode pair 15 and another electrode pair 17. Two or more mating partners may be positioned between the electrode pairs 15, 17. The total electrode force 27 is applied to the electrode pairs 15 and 17 by means of the force source 19. In this way, the joining partner is temporarily fixed between the electrode pairs 15, 17 and pressed together so that the two welding currents provided by the welding transformer (Schweisstransformator) 2 and the other welding transformer 3 at least partially melt the material of the joining partner And as a result, the joint counterparts are connected at the two joint locations by means of resistance welding.

[0026] The welding transformers 2 and 3 are connected to the moving welding electrodes 39, 41 of the welding electrode pair 15, 17 by means of a secondary cable (Sekundaerst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com